Method for controlling gripper

A gripper and control cylinder technology, applied in the field of gripper control, can solve problems such as influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

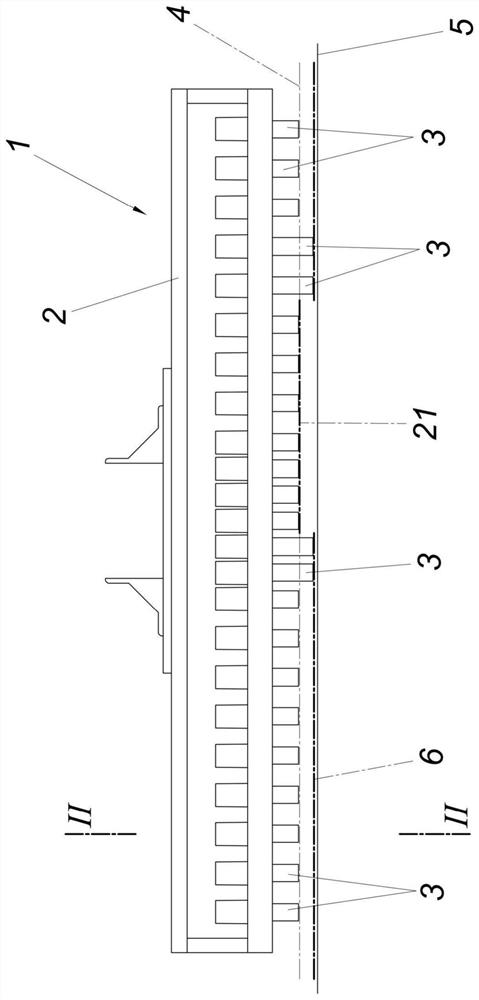

[0017] The gripper 1 according to the invention has a frame 2 in which a plurality of gripping elements 3 are arranged. These gripping elements 3 form a reference plane 4 which extends parallel to a flat support 5 for a material web 6, for example pre-impregnated or dry fiber material, a material or leather web, a film or analog. The gripping elements 3 are distributed in a grid-like manner in the reference plane 4, as can be obtained from Figure 5 seen in. The grid-like distribution does not have to be uniform. A denser distribution can be provided in areas where the outlines of individual billets are piled up, such as by Figure 5 The center area of the gripper 1 is shown.

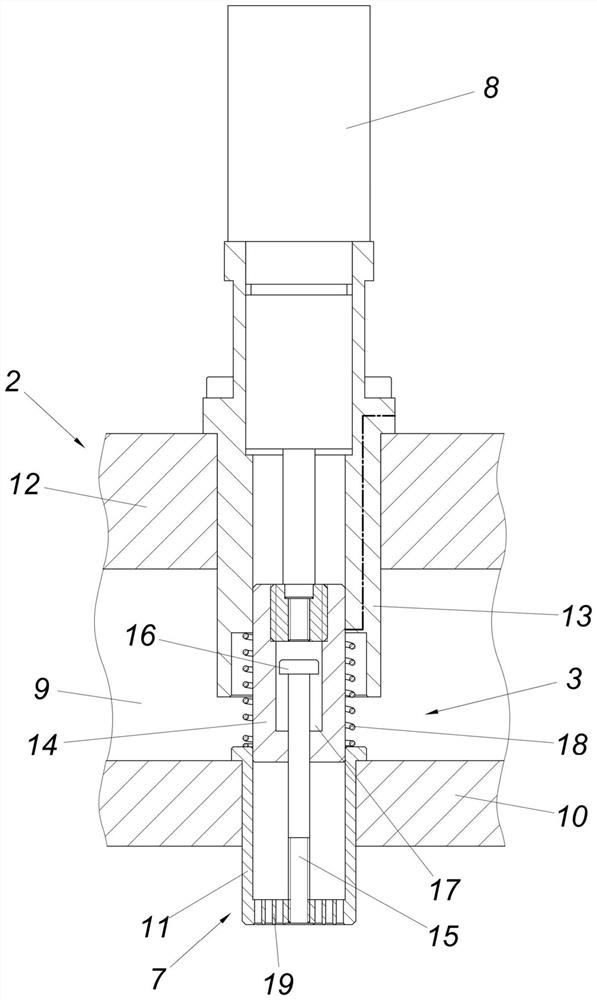

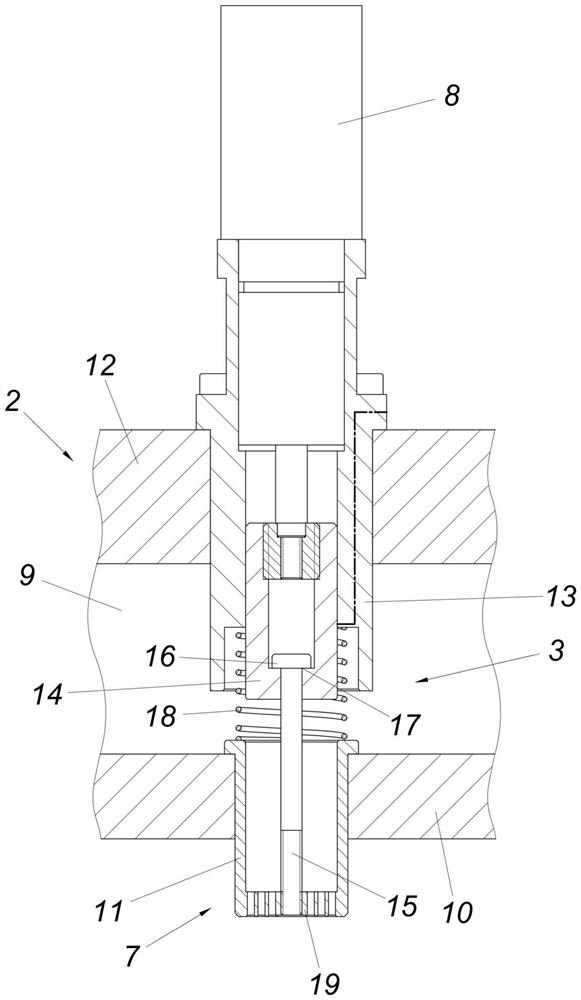

[0018] Although the gripping element 3 can, depending on the properties of the material web 6, clamp the blank, for example mechanically or magnetically, for most applications an advantageous dimension is obtained with the gripping element 3 forming the suction head 7, as shown in Figures 2 to 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com