Coffee yogurt flavoured seasoning and production process thereof

A technology of seasoning and caffeic acid, which is applied in the field of coffee yogurt flavor seasoning and its production technology, to achieve the effects of extending shelf life, reducing caking, and optimizing moisture absorption stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] The present embodiment prepares a kind of stabilizing agent, concrete process is as follows:

[0042] Weigh 1 kg of silicon dioxide, 0.3 kg of microcrystalline cellulose and 0.2 kg of sodium alginate, add them into a stirrer, and stir for 10 minutes to prepare a stabilizer.

Embodiment 2

[0044] The present embodiment prepares a kind of coffee yoghurt flavor seasoning, specifically as follows:

[0045] Weigh the following raw materials: whey powder 30kg, white sugar 15kg, maltodextrin 10kg, edible salt 5kg, instant coffee powder 5kg, skimmed milk powder 5kg, yogurt essence 1kg, coffee essence 1kg, edible glucose 1kg, low-fat yogurt powder 1kg , cheese powder 1kg, cocoa powder 1kg, stabilizer 0.1kg prepared in embodiment 1, citric acid 0.1kg, lactic acid 0.1kg, calcium lactate 0.1kg, aspartame 0.1kg;

[0046] The concrete preparation process of this kind of coffee yoghurt flavor seasoning is as follows:

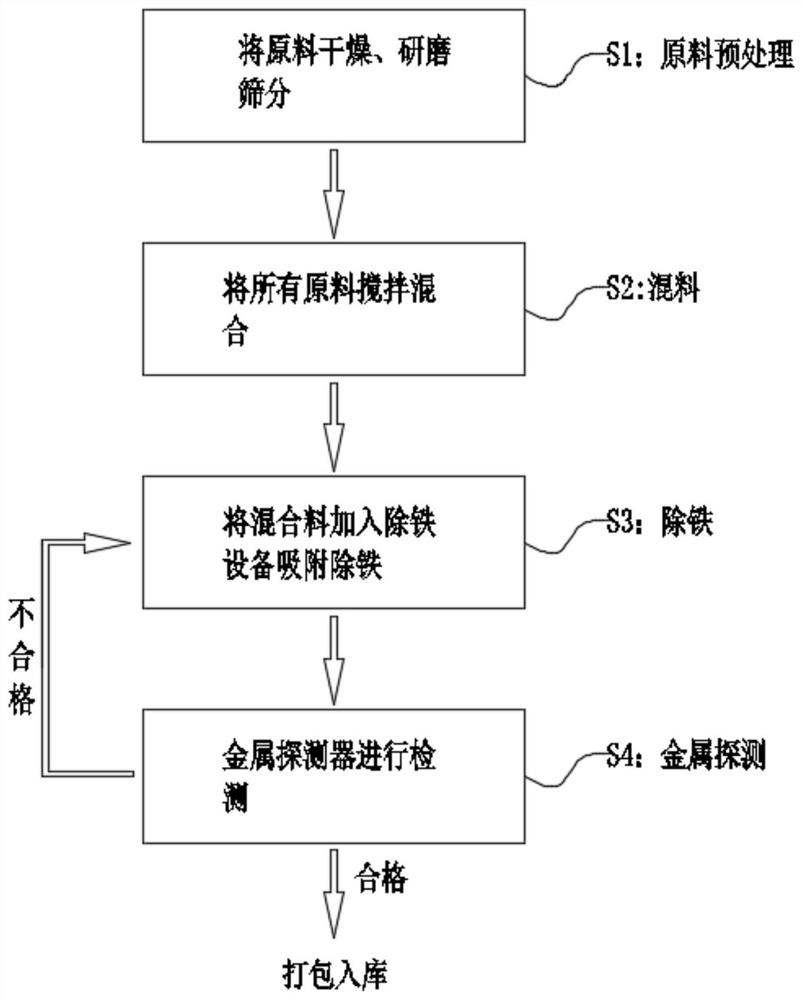

[0047] Raw material pretreatment: Dry the qualified raw materials at 42°C with low-temperature hot air until the water content of the raw materials does not exceed 1.2%, and then pass through an 80-mesh sieve to take the under-sieved powder;

[0048] Mixing: Weigh the yogurt essence, coffee essence, lactic acid and stabilizer according to the weight part for p...

Embodiment 3

[0054] The specific preparation steps of this example are the same as those of Example 1. The raw material pretreatment process is carried out with hot air drying at 45°C, and the stirring speed during the mixing process is 280r / min. The seasoning includes the following raw materials: whey powder 35kg, white sugar 17kg , maltodextrin 13kg, edible salt 7kg, instant coffee powder 8kg, skimmed milk powder 7kg, yogurt essence 3kg, coffee essence 3kg, edible glucose 3kg, low-fat yogurt powder 3kg, cheese powder 3kg, cocoa powder 3kg, embodiment 1 preparation Stabilizer 0.4kg, citric acid 0.4kg, lactic acid 0.4kg, calcium lactate 0.4kg, aspartame 0.4kg.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com