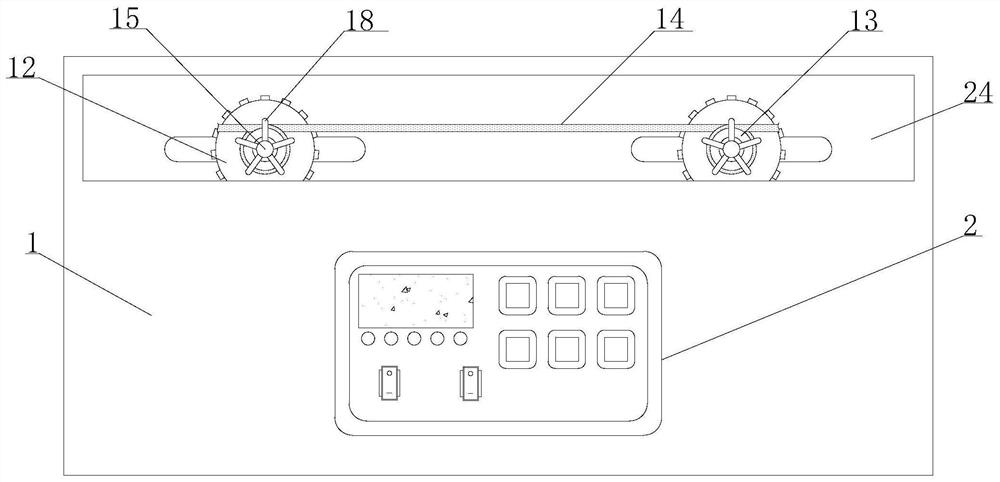

Coaxial cable tension test device

A technology of tensile test and coaxial cable, which is applied in the direction of measuring devices, using stable tension/pressure testing material strength, instruments, etc., can solve the problems of reducing stretching efficiency, wasting experiment time, and affecting stretching time, etc., to achieve Effects of improving accuracy, improving fastness, and improving stretching efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

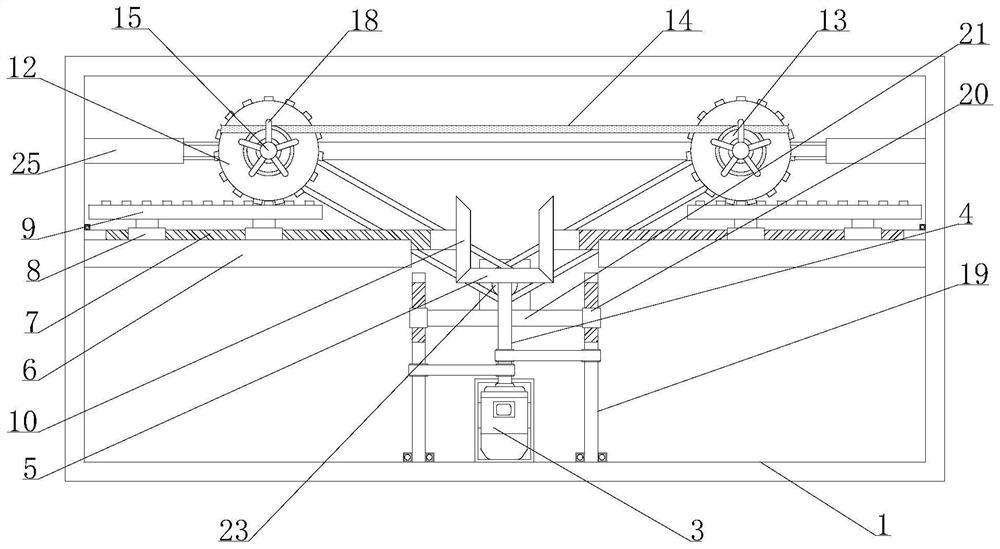

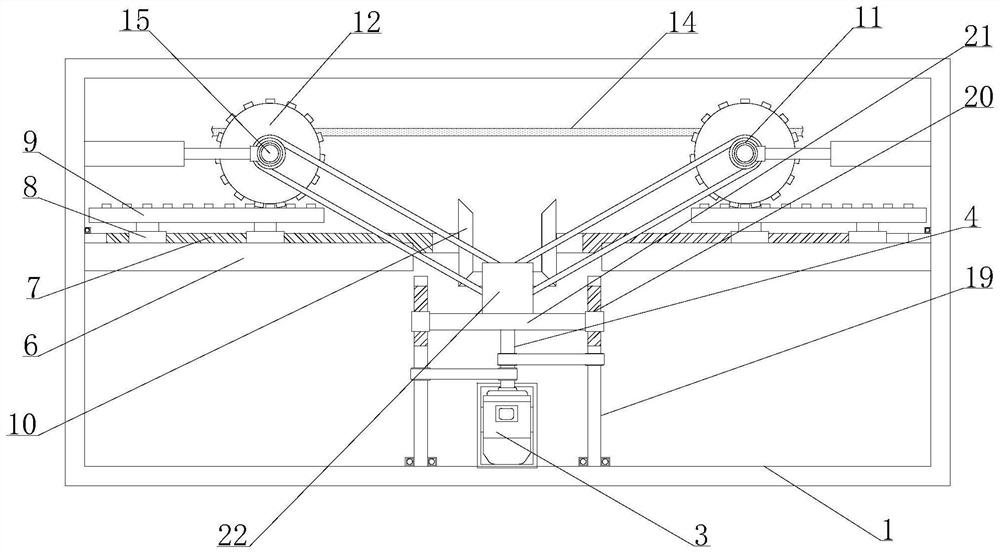

[0037] Embodiment 1, when the adjustment gear 12 moves in the opposite direction, the first transmission rod 4 drives the second rotating screw rod 19 to rotate through the crawler belt, so that the second sliding nut 20 on the surface of the second rotating screw rod 19 drives the second rotating screw rod 19 through the bearing plate 21. The second driving motor 22 moves up, thereby keeping the distance between the second transmission rod 23 and the second installation rod 15, making it convenient for the second transmission rod 23 to drive the first installation rod 11 to rotate through the crawler belt, and when the adjustment gear 12 moves oppositely , the upper side of the adjustment rod 9 will drive the adjustment gear 12 to rotate slowly in the opposite direction, and then the adjustment gear 12 will drive the first installation rod 11 to rotate slowly in the opposite direction, so that the track will rotate relatively on the surface of the first installation rod 11 with...

Embodiment 2

[0038] Embodiment 2, when the adjustment gear 12 moves in the opposite direction, the first installation rod 11 slides on the upper side of the isolation plate 24, and at the same time, the other end of the second installation rod 15 slides on both sides of one end inside the housing 1 through the auxiliary wheel 17 , so that when the adjusting gear 12 moves in the opposite direction, the stability of the installation shaft 13 pulling the cable body 14 is improved.

[0039] Working principle: before use, power on the control panel 2, the first drive motor 3, the second drive motor 22, the first electric cylinder 16 and the second drive motor 22, and wrap the two ends of the cable body 14 to be detected on the The surface of the installation shaft 13 on both sides. At this time, the first electric cylinder 16 drives the second installation rod 15 to shrink, and then the second installation rod 15 clamps the cable body 14 on the surface of the installation shaft 13 through the fa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com