Valve plate test line and test method

A test method and test line technology, applied in the field of transmission, can solve the problems of low efficiency and accuracy, cannot meet the production needs of valve plates, etc., achieve the effect of improving accuracy, providing test efficiency and test accuracy, and improving test efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

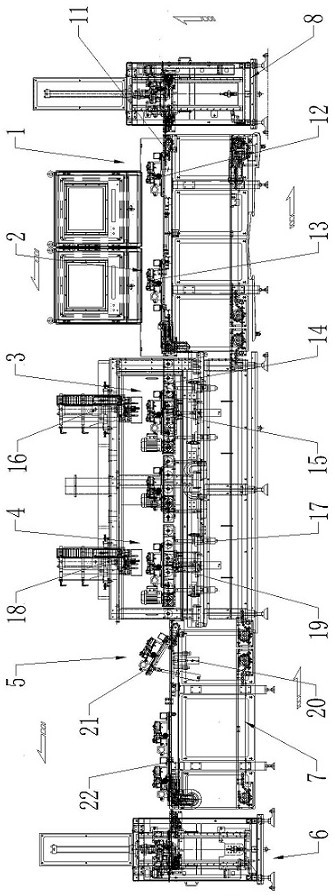

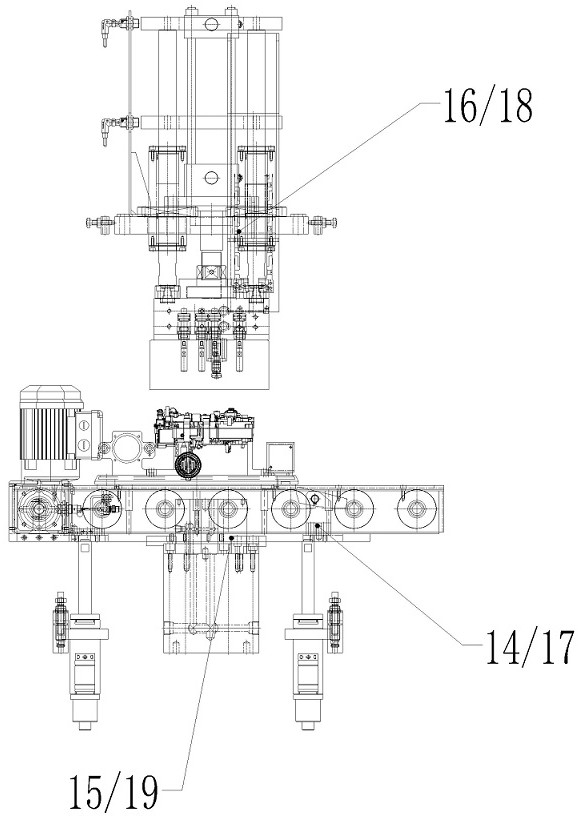

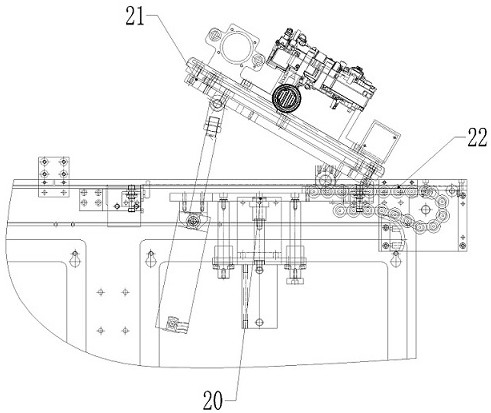

[0060] like figure 1 As shown, the valve plate test line includes a test conveying line. In the conveying direction of the test conveying line, the off-line station 1 for qualified products, the on-line station 2, the washing station 3, the test station 4, and the off-line station for unqualified products are arranged in sequence. Line station 5. In order to match the efficiency of the test line, several waiting stations can be set between the on-line station 2 and the flushing station 3, between the flushing station 3 and the test station 4, etc., to adjust the speed of the test line. It also includes a pallet 12 for loading the valve plate 13; the pallet 12 has a code, and the code of the pallet 12 on the test conveying line is unique, and is used for identifying the pallet 12. Each station has code reader, is used for reading the code on pallet 12. Among them, the code reader adopts the existing products on the market.

[0061] Among them, the on-line station 2 and the q...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com