A mineral impurity separation device for oil extraction

A technology for oil extraction and separation devices, applied in separation methods, filtration separation, chemical instruments and methods, etc., can solve the problems of easy accumulation of residual small minerals, decreased effect, and inconvenience for quick removal of impurities, reducing time and enhancing stability. , easy to extract and use the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

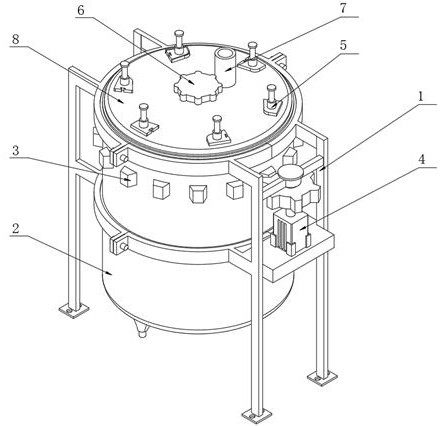

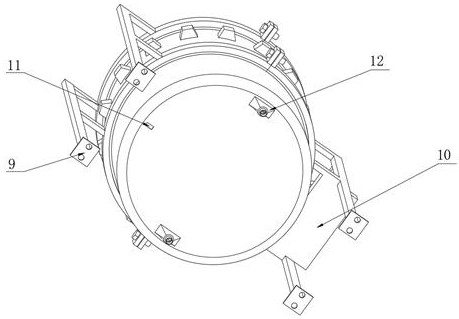

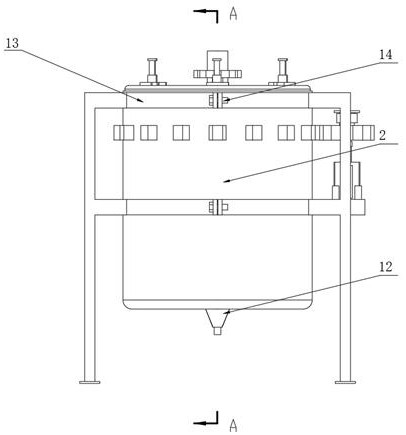

[0036] Such as Figure 1-13As shown, a mineral impurity separation device for oil exploitation includes a side support 1 and a storage tank 2, two side supports 1 are provided, and the corresponding surfaces of the two side supports 1 are integrally provided with a C-shaped limiter. Position rods 13, each C-type limit rod 13 is fixedly connected by fixing bolts 14, each C-type limit rod 13 inner wall is provided with a matching sliding groove 21, and the outer surface of the storage tank 2 is respectively integrally provided with a matching Sliding rings 24, the outer circumference of each matching sliding ring 24 is limitedly matched with the corresponding matching sliding groove 21, and the first matching teeth 3 are integrally provided between the two matching sliding rings 24 and on the outer surface of the storage tank 2. The inner wall of the tank 2 is respectively equipped with a number of separation components 5, and the inner bottom of the storage tank 2 is equipped w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com