Detection device for motor shaft

A detection device, motor shaft technology, applied in the direction of measuring device, using sound wave/ultrasonic wave/infrasonic wave to analyze solids, using sound wave/ultrasonic wave/infrasonic wave to analyze materials, etc. It can solve the problems of insufficient shaft radius, failure, stress concentration, etc., and achieve The effect of improving usability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

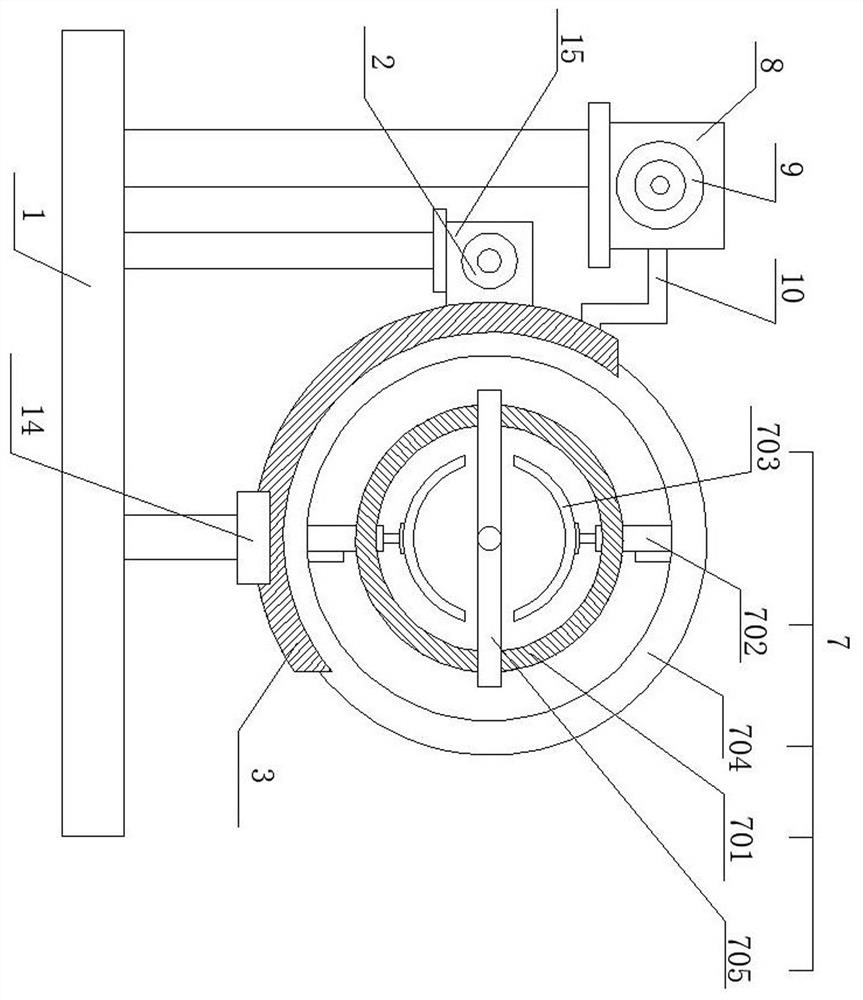

[0036] Example: refer to Figure 1-8 , a detection device for the motor shaft, including a detection workbench 1, a shaft support plate 11, a rotating clamping mechanism 7, an equipment rack 4, a transverse flaw detection mechanism, a moving mechanism and a torque sensor 19, and three groups are arranged above the detection workbench 1 The equipment frame 4 and the fixed plate 13 , and the transverse flaw detection mechanism and the moving mechanism are correspondingly arranged between the equipment frame 4 and the fixed plate 13 .

[0037] Further, the bottoms of the equipment frame 4 and the fixed plate 13 are bolted to the table top of the inspection table 1, and the cooperation between the equipment frame 4 and the fixed plate 13 plays the role of installation support for the setting of the transverse flaw detection mechanism and the moving mechanism.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com