High-position automatic water spraying noise reduction system following rocket exhaust plume

A technology of noise reduction system and water supply system, which is applied in the direction of rocket launcher, offensive equipment, weapon type, etc. It can solve the problems that the noise reduction water cannot reach in time and affect the noise reduction effect of high-level water spraying, so as to avoid low-frequency vibration, Reduced water hammer effect and excellent noise reduction performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in detail below with reference to the accompanying drawings and examples.

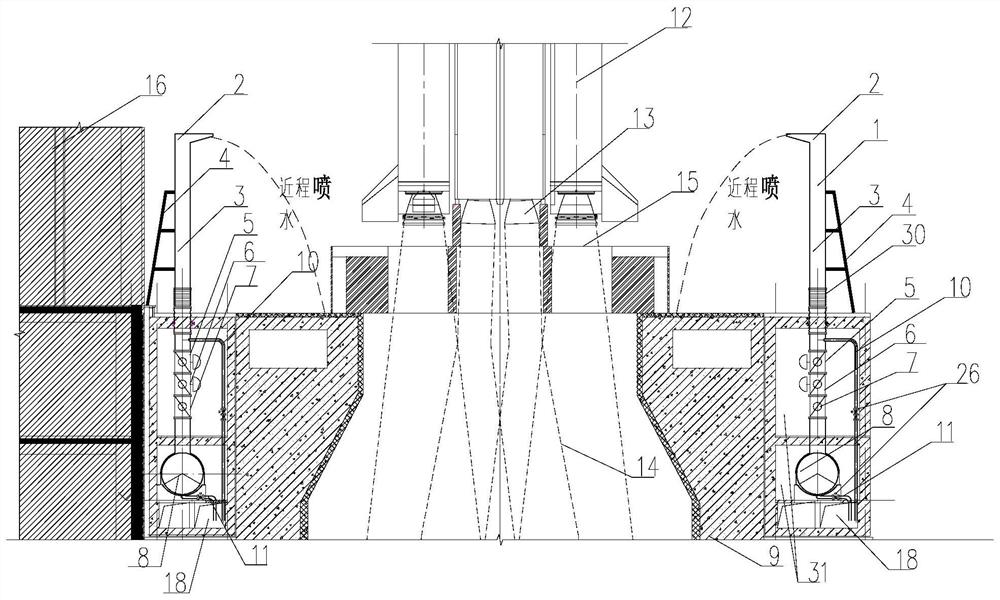

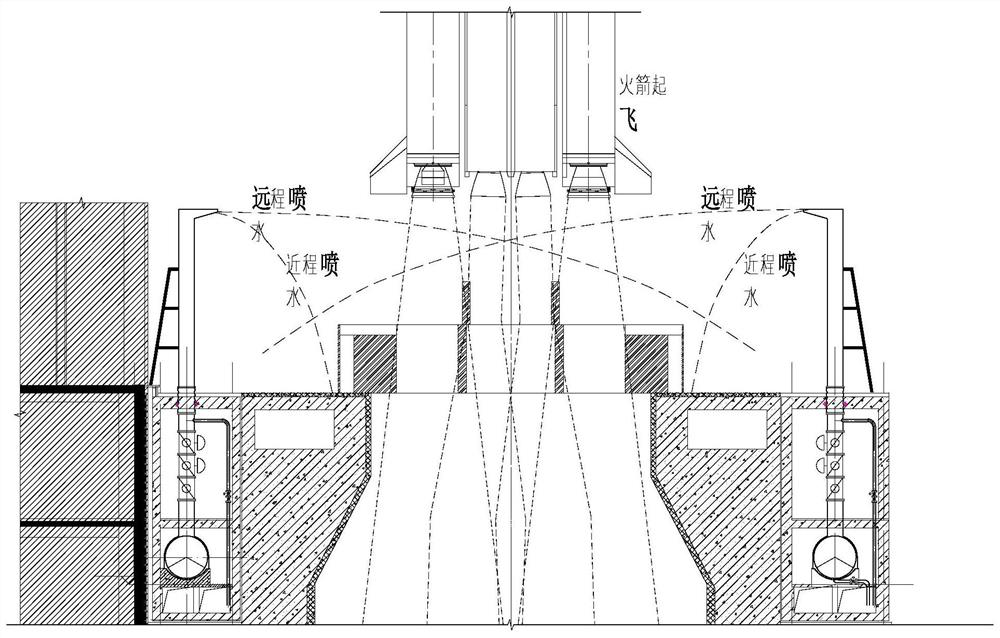

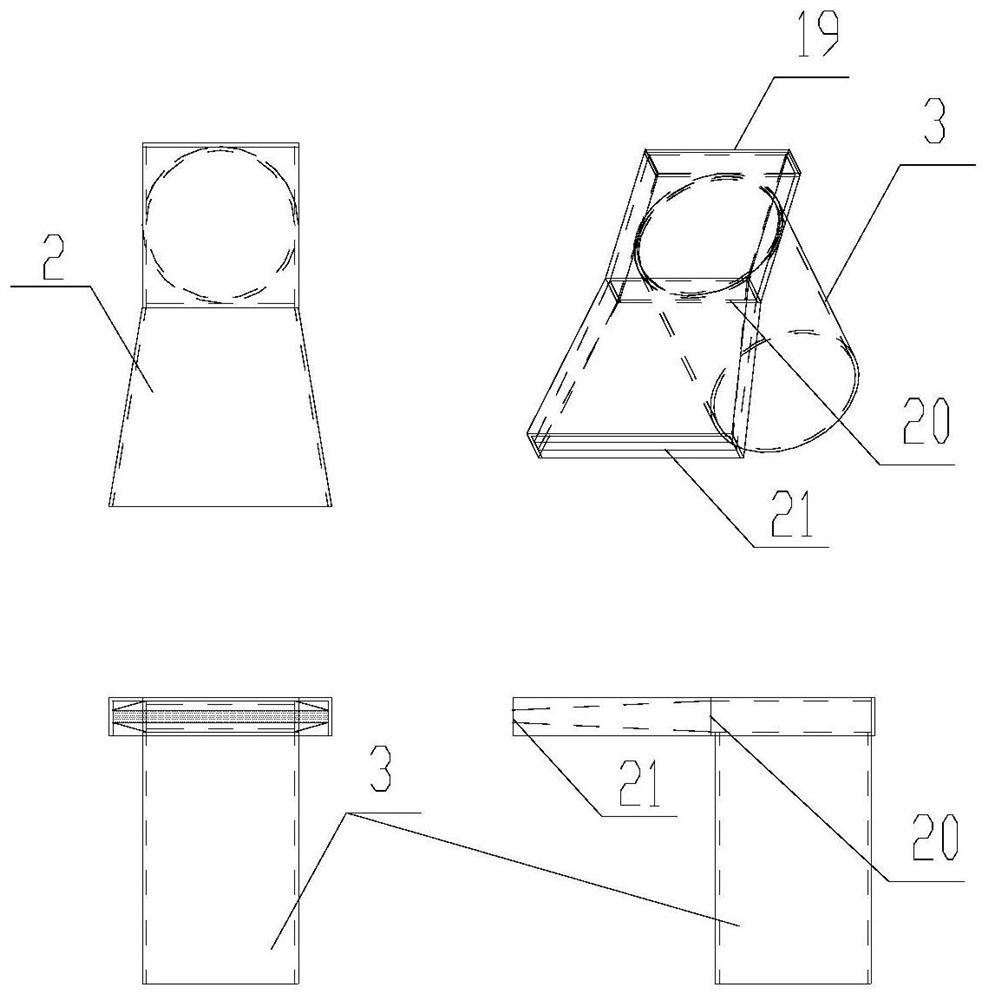

[0029] as attached figure 1 with 2 As shown, the present invention provides a high-level automatic water spray noise reduction system following rocket plume, which system includes nozzle 2, water spray pipeline 3, fast valve control system, air supply system, water supply system and drainage system.

[0030] Wherein, the water supply system is located at the top of the launch tower 16, and the nozzles 2 are connected to the water supply system through the water spray pipeline 3. The nozzles 2 are evenly arranged on the front and rear sides of the launch station. After the nozzles 2 spray water stably, the water spray range can cover the launch platform 15. , just below the launch pad 15 is a diversion groove 9 for guiding gas jets and cooling and noise-reducing water vapor. Image 6 shown.

[0031] The rapid valve control system is set on the water spra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com