Mechanical workpiece grooving equipment and grooving method thereof

A technology for slotting equipment and workpieces, applied in metal processing equipment, metal processing machinery parts, measuring/indicating equipment, etc., can solve problems such as automatic detection of slotting quality, reduce the number of settings and layout space, and reduce the time for completion , Guarantee the effect of quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

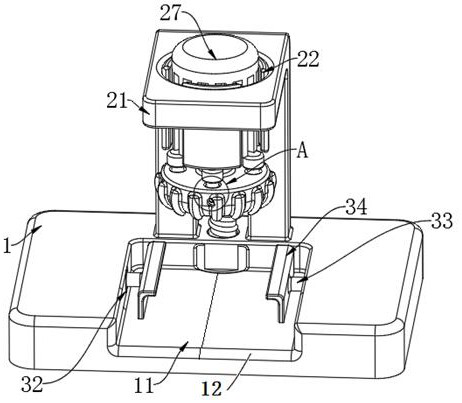

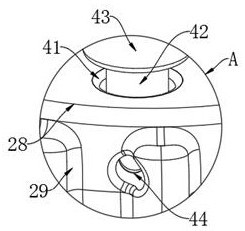

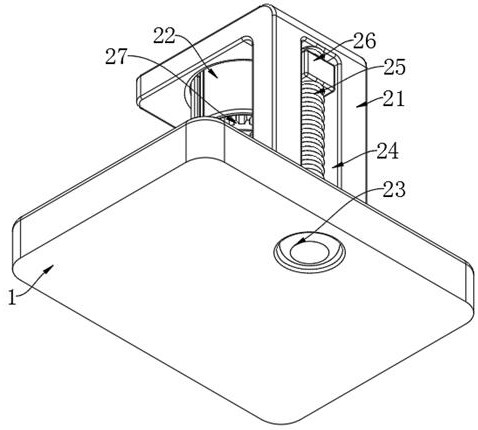

[0038] Combine below Figure 1 to Figure 5 , the present invention is further described:

[0039] Such as Figure 1-3As shown, embodiment 1: a mechanical workpiece slotting equipment, including a metal pin cutter 29, a first servo motor 23 and a clamping fixture 34, the first servo motor 23 makes the metal pin cutter 29 vertically The metal workpiece 7 is moved and notched.

[0040] The first transmission structure includes a mounting bracket 21, a threaded rod 25 and a moving nut 26. The horizontal portion of the mounting bracket 21 is provided with a motor mounting hole 22 for installing the second servo motor 27, and the vertical portion of the mounting bracket 21 is provided with a long slot for screw rod installation. 24. One end of the threaded rod 25 is connected to the first servo motor 27 and is rotated by the first servo motor 27. The threaded rod 25 is connected to the thread inside the moving nut 26, and the outside of the moving nut 26 is connected to the mounti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com