Painting device for narrow vertical face of furniture

A narrow and façade technology, applied in the field of furniture narrow façade varnishing devices, can solve the problems that furniture cannot be fully and effectively protected by paint and cannot be painted, so as to avoid dead spots of spraying, good adaptability, and avoid relative sliding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

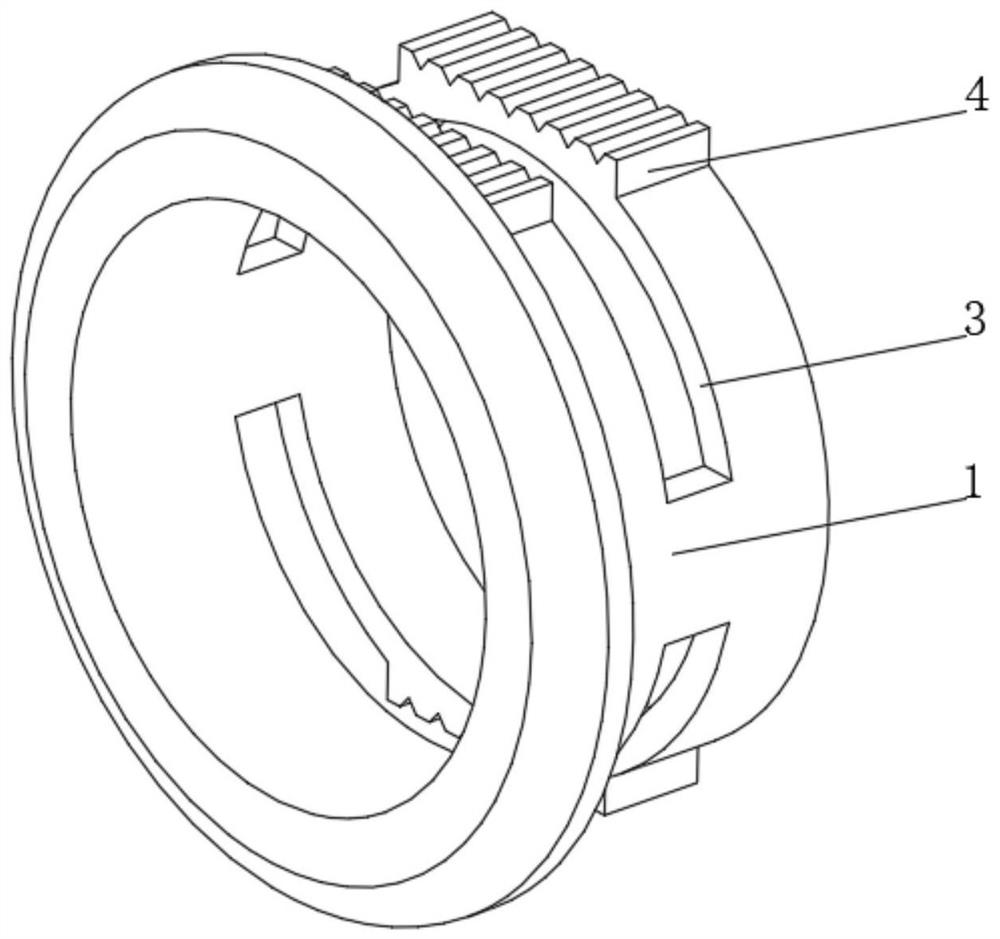

[0035] see Figure 1-3 , the present invention provides a technical solution: a furniture narrow facade painting device, specifically comprising:

[0036] Spraying shell 1, one side of the spraying shell 1 runs through and is fixedly connected with a rotating spraying device 2, the top and bottom of the spraying shell 1 are provided with adjustment chute 3, and the outer parts of the spraying shell 1 located on both sides of the adjustment chute 3 are fixedly connected There is a fixed platform 4;

[0037] A fixing device 5, one side of the fixing device 5 is fixedly connected to one side of the rotating spraying device 2, and one side of the fixing device 5 is fixedly connected to an external handle through a connecting rod 6;

[0038] Fixture 5 includes:

[0039] A fixed seat 51, the top and bottom of the fixed seat 51 are provided with a fixed groove 52, and one side of the fixed seat 51 is fixedly connected with the rotating spraying device 2;

[0040] Sliding bracket 5...

Embodiment 2

[0043] see Figure 1-4 On the basis of Embodiment 1, the present invention provides a technical solution: the clamping device 54 is provided with two groups and distributed symmetrically with respect to the center position of the sliding bracket 53, the clamping device 54 includes a splint 541, and the top of the splint 541 is provided with a sliding channel. Hole 542, the inner wall of sliding through hole 542 is slidably connected with control board 543, and the side of control board 543 is provided with fixing hole 544, and the inner wall of fixing hole 544 is threaded with fixing screw rod 545, and both ends of fixing screw rod 545 are threadedly connected with splint 541, splint 541 One end extends to the inside of the sliding bracket 53 and is slidably connected with the inner wall of the sliding bracket 53. One end of the fixing screw 545 penetrates the splint 541 and extends to the outside of the splint 541. The fixing holes 544 are arranged in multiple groups and evenl...

Embodiment 3

[0045] see Figure 1-5 , on the basis of Embodiment 1 and Embodiment 2, the present invention provides a technical solution: the rotary spraying device 2 includes a fixed casing 21, one side of the fixed casing 21 penetrates and is fixedly connected with an electronic rotary table 22, and the electronic rotary table 22 is located in the spraying One side inside the shell 21 is fixedly connected with a connecting rod 23, and one end of the connecting rod 23 away from the resistance rotary table 22 is fixedly connected with a spraying head 24, and the outside of the spraying head 24 is rotationally connected with the inner wall of the fixed shell 21 through a sealed bearing. The inner wall of the shell 1 is fixedly connected, one end of the spraying head 24 extends to the inside of the spraying shell 1, and one side of the fixed shell 21 is connected with the external paint delivery equipment through a pipeline, and a rotating spraying device 2 is provided. When spraying, the spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com