An atomizing spraying device for a mechanical processing workshop

A spraying device and machining technology, applied in spraying devices, spraying devices with movable outlets, liquid spraying devices, etc., can solve the problems of inability to automatically adjust the spraying position and spraying angle, inconvenient for factories to use for a long time, and increase the cost of dust removal. , to achieve the effect of improving the dust removal effect, avoiding frequent adjustments and reducing dust removal costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

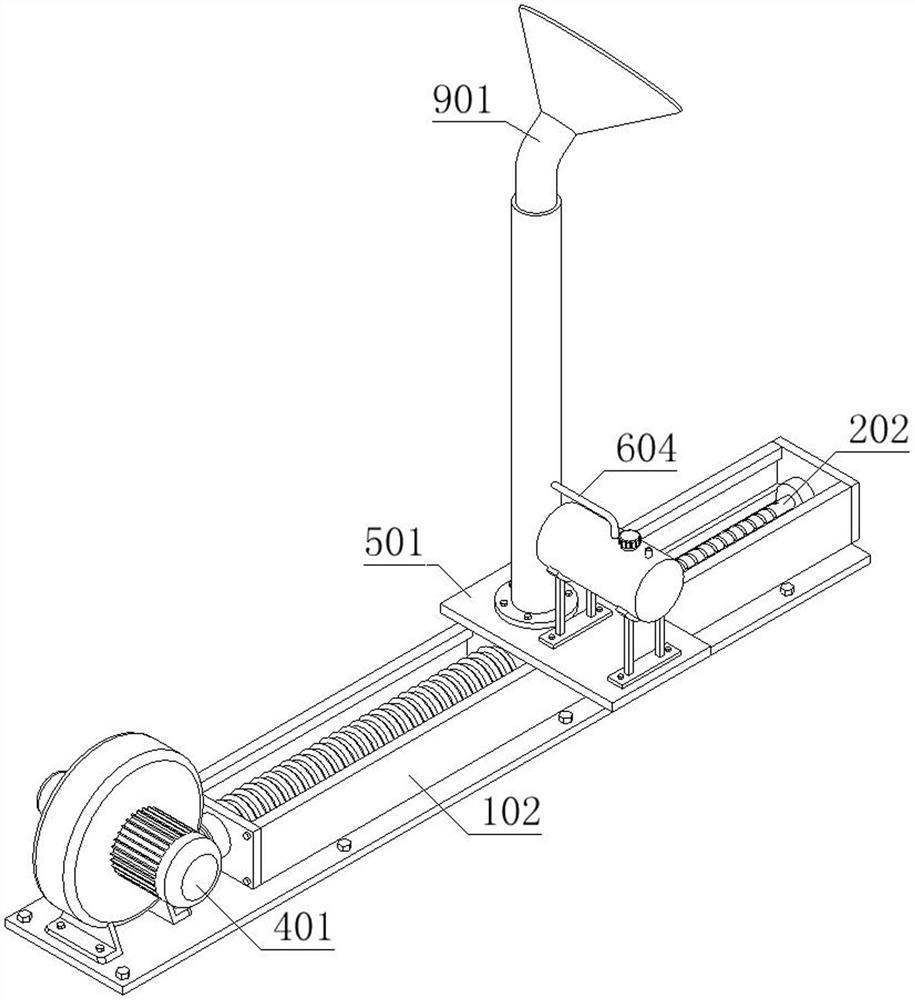

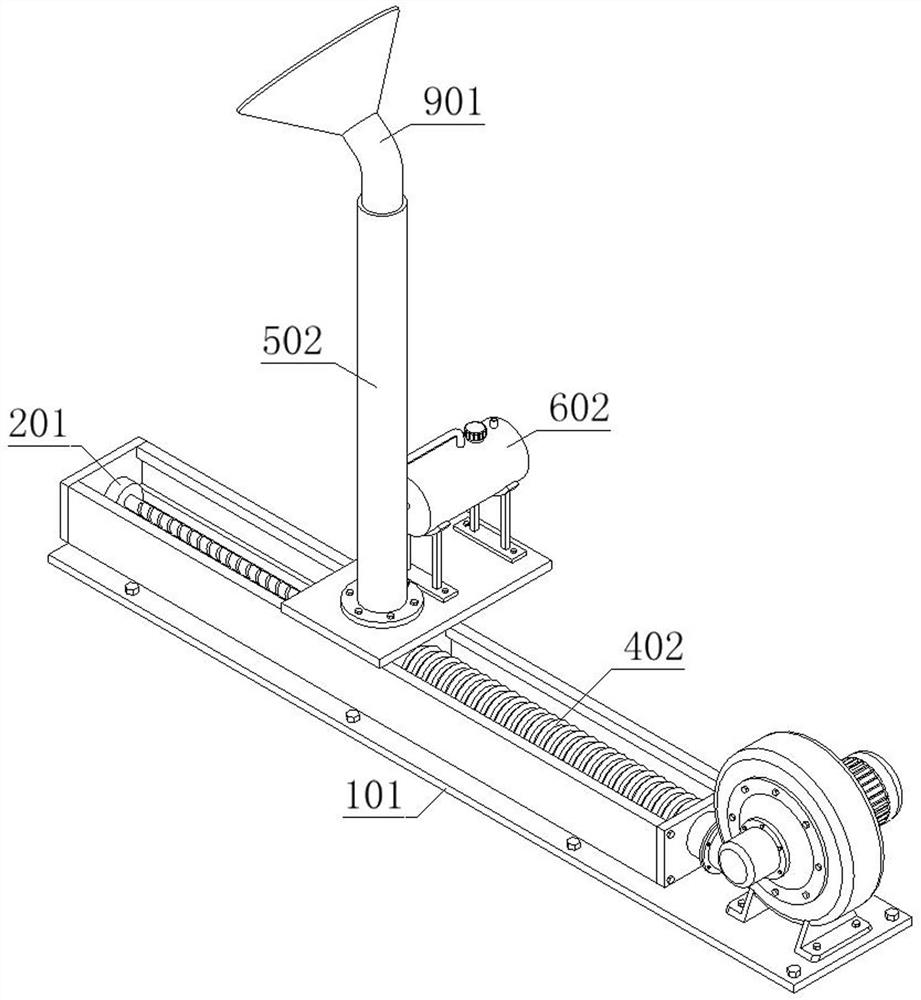

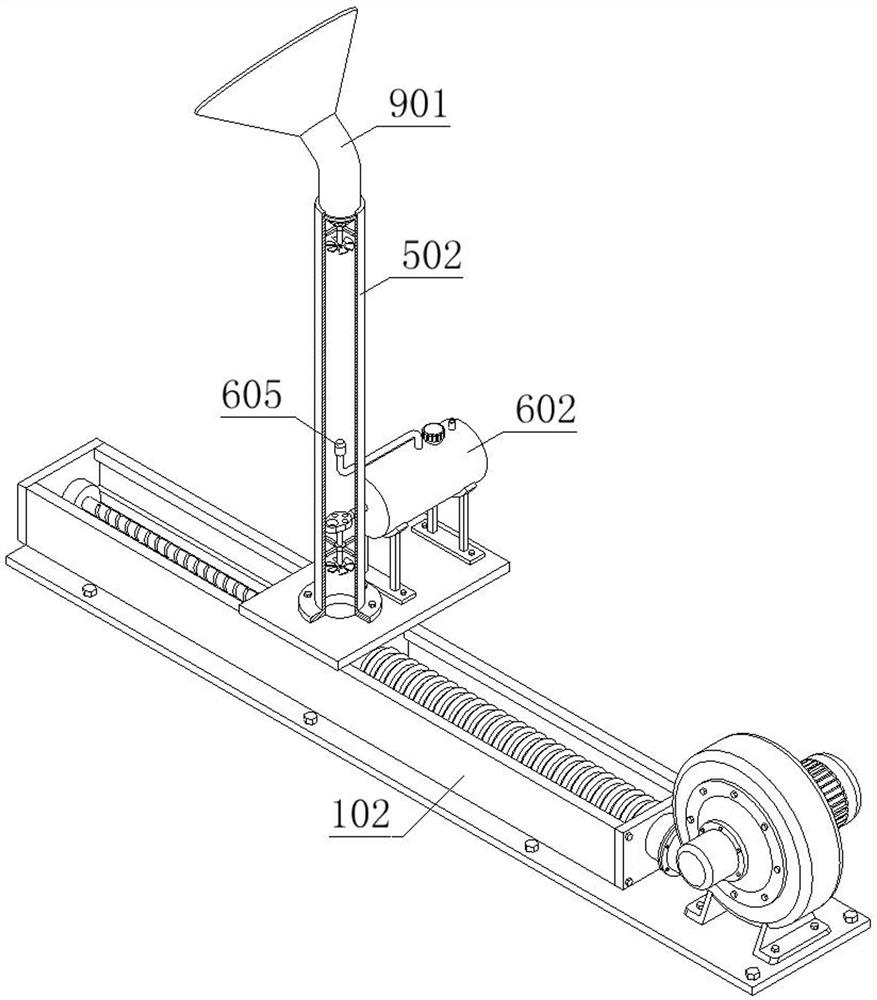

[0082] as attached figure 1 to attach Figure 17 Shown:

[0083] The present invention provides an atomizing spraying device for mechanical processing workshops, which includes a fixed assembly 1; an adjustment mechanism 2 and a sliding device 3 are installed inside the fixed assembly 1, and a driving part 4 is installed on the top of the fixed assembly 1, and the sliding device 3 The top of the installation mechanism 5 is installed; the atomization part 6, the atomization part 6 is installed on the top of the installation mechanism 5, and the interior of the installation mechanism 5 is installed with a push mechanism 7 and a connection assembly 8, and the top of the installation mechanism 5 is installed with a spray device9.

[0084] Such as Figure 5 to Figure 8 As shown, the fixed assembly 1 includes: a base plate 101, the base plate 101 is a rectangular plate-shaped structure; a slide rail 102, the slide rail 102 is fixedly installed on the top of the base plate 101, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com