Manufacturing method of medical bandage

A production method and technology of strapping, which are applied in metal processing, breathing masks, etc., can solve the problems of easy to fall off, easy to cause hygienic problems, affect comfort, etc., and achieve the effect of comfortable wearing, not easy to fall off, and good hygiene.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] This part will describe the specific embodiment of the present invention in detail, and the preferred embodiment of the present invention is shown in the accompanying drawings. Each technical feature and overall technical solution of the invention, but it should not be understood as a limitation on the protection scope of the present invention.

[0032] A method for manufacturing a medical bandage, comprising the steps of:

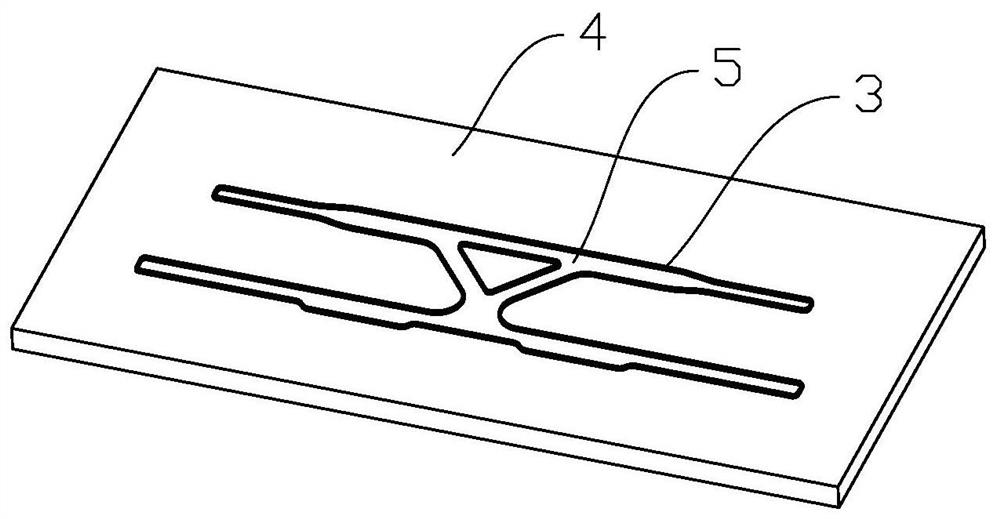

[0033] A. Prepare a raw material belt 1, such as Figure 6 As shown, the raw material belt 1 includes a Velcro cloth 101 with suede, a sponge sheet 102 and an elastic Lycra cloth 103, and the Velcro cloth and the Lycra cloth are pasted and fixed on the sponge sheet respectively by air-permeable glue. Up below; design a cutter 3 according to the shape of the required strap 2, and fix the cutter 3 on the flat panel 4, the cutter 3 is made of a material with high thermal conductivity, and the flat panel 4 is made of a material with low thermal conduct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com