Making method of snakehead-basal tail shrimp paste product

A production method and technology of basil shrimp are applied in the directions of food ingredients as gelling agents, food ingredients, food science, etc., to achieve the effects of increasing protein content, enhancing functional properties, and improving gel properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] A kind of preparation method of snakeheaded fish-base tail shrimp slippery product, carry out according to the following steps:

[0040](1) Cleaning and peeling of fish meat: rinse the black fish with clean water, select the back fish meat, wash and peel;

[0041] (2) Cleaning and peeling of shrimp meat: rinse the base tail shrimp with clear water, remove the shrimp head and shrimp skin;

[0042] (3) Sample preparation: Add 180g of shrimp meat, 20g of black fish meat, 18g of pig fat, 4g of salt, 12g of egg white, and 18g of starch into a chopping machine and mix for 3 minutes. Heat in a water bath, heat at 90°C for 30 minutes, and then quickly put it into ice water at 0°C for cooling. After cooling, the black fish-base tail shrimp slip product is obtained, and place it in a refrigerator at 4°C for 12 hours, and set aside;

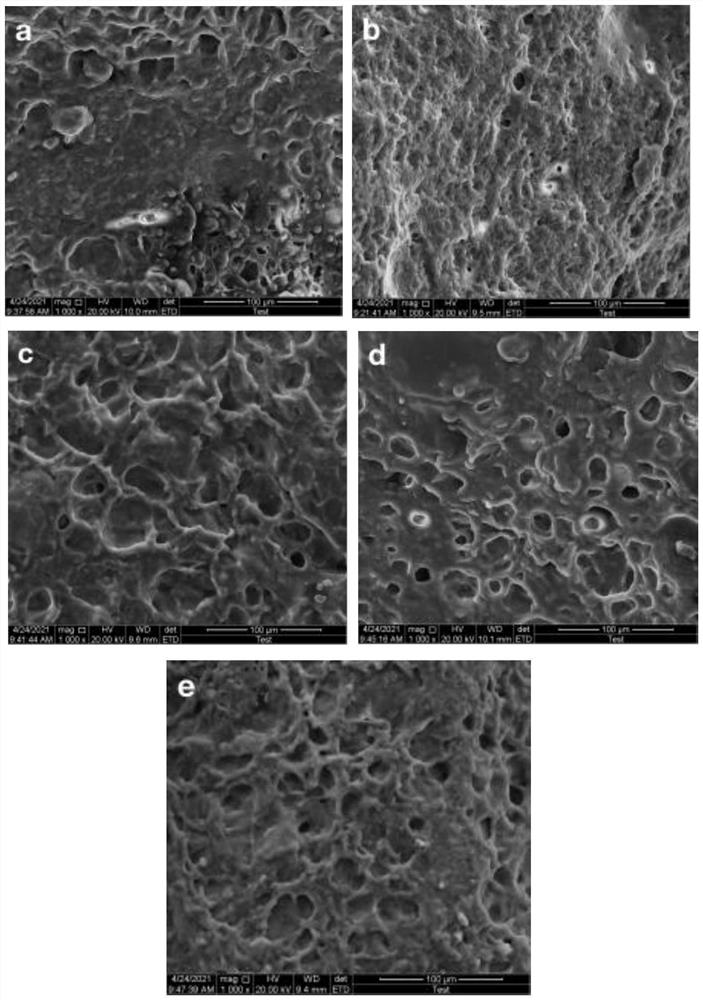

[0043] (4) Preparation of SEM samples: each gel sample was cut into a cube of 3×3×1 mm, and freeze-dried for 24 hours using the FD-1A-50 freeze dry...

Embodiment 2

[0048] A kind of preparation method of snakeheaded fish-base tail shrimp slippery product, carry out according to the following steps:

[0049] (1) Cleaning and peeling of fish meat: rinse the black fish with clean water, select the back fish meat, wash and peel;

[0050] (2) Cleaning and peeling of shrimp meat: rinse the base tail shrimp with clear water, remove the shrimp head and shrimp skin;

[0051] (3) Sample preparation: add 160g shrimp meat, 40g fish meat, 18g pig fat, 4g salt, 12g egg white, and 18g starch into the chopping machine and mix for 3 minutes. Heat in a water bath, heat at 90°C for 30 minutes, and then quickly put it into ice water at 0°C for cooling. After cooling, the black fish-base tail shrimp slip product is obtained, and place it in a refrigerator at 4°C for 12 hours, and set aside;

[0052] (4) Preparation of SEM samples: each gel sample was cut into a cube of 3×3×1 mm, and freeze-dried for 24 hours using the FD-1A-50 freeze dryer produced by Beijin...

Embodiment 3

[0057] A kind of preparation method of snakeheaded fish-base tail shrimp slippery product, carry out according to the following steps:

[0058] (1) Cleaning and peeling of fish meat: rinse the black fish with clean water, select the back fish meat, wash and peel;

[0059] (2) Cleaning and peeling of shrimp meat: rinse the base tail shrimp with clear water, remove the shrimp head and shrimp skin;

[0060] (3) Preparation of samples: Add 140g shrimp meat, 60g black fish meat, 18g pig fat, 4g salt, 12g egg white, and 18g starch into the chopping machine and mix for 3 minutes. Heat in a water bath, heat at 90°C for 30 minutes, and then quickly put it into ice water at 0°C for cooling. After cooling, the black fish-base tail shrimp slip product is obtained, and place it in a refrigerator at 4°C for 12 hours, and set aside;

[0061] (4) Preparation of SEM samples: each gel sample was cut into a cube of 3×3×1 mm, and freeze-dried for 24 hours using the FD-1A-50 freeze dryer produced...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com