Novel high-voltage SF6 self-energy blowing-assisted circuit breaker arc extinguish chamber

A circuit breaker, SF6 technology, applied in high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve problems such as reducing the reliability of breaking short-circuit current, high post-arcing temperature between contacts, and affecting medium recovery speed. , to achieve the effect of being conducive to arc extinguishing, short arcing time, and improving work reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

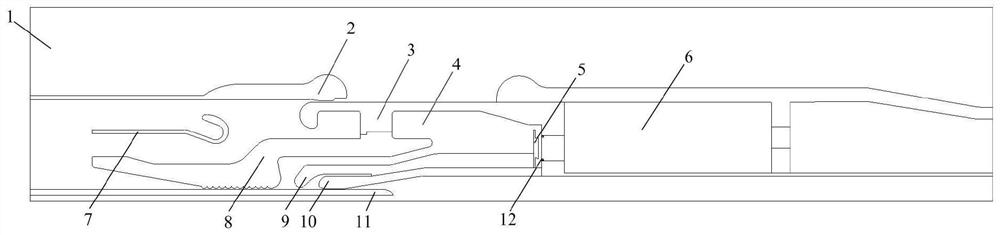

[0023] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

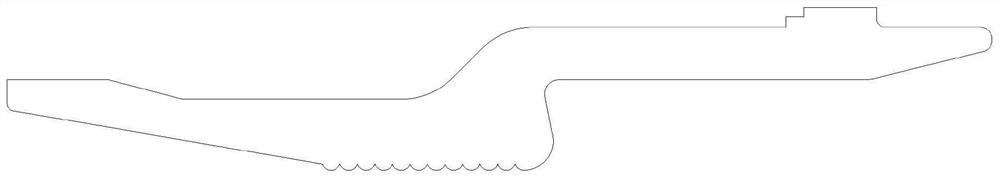

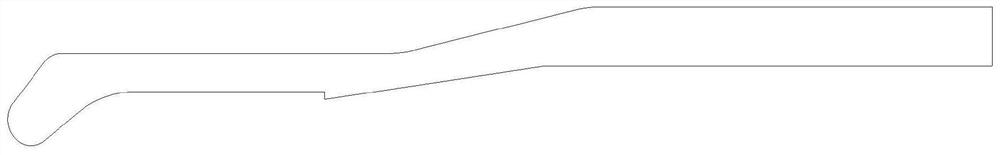

[0024] In this example, the high pressure SF 6 Self-energy blown circuit breaker arc extinguishing chamber such as figure 1 shown, including SF 6 Gas zone 1, static main contact 2, moving main contact 3, expansion chamber 4, one-way valve 5, pressure cylinder 6, shield cover 7, large nozzle 8, small nozzle 9, moving arc contact 10 and static arc contact head; a novel high pressure SF of the present invention 6 On the basis of the existing arc extinguishing chamber structure, the self-energy-assisted blowing type circuit breaker arc extinguishing chamber modifies the large nozzle, small nozzle, static arc contact and one-way valve as follows figure 2 Large spout with r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com