Cylindrical cabin section wallboard structure simulation static test device and method

A static test and plate structure technology, applied in the field of aerospace mechanics testing, can solve problems such as over-examination of cabin structure, under-examination of panel structure, distortion of force transmission path, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

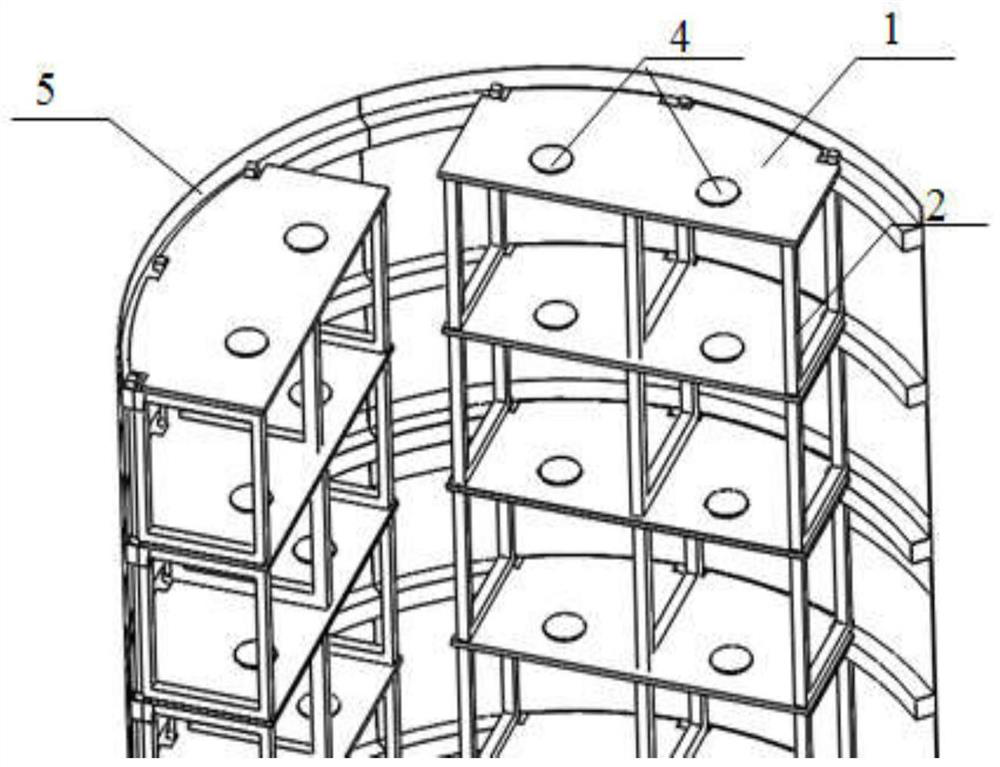

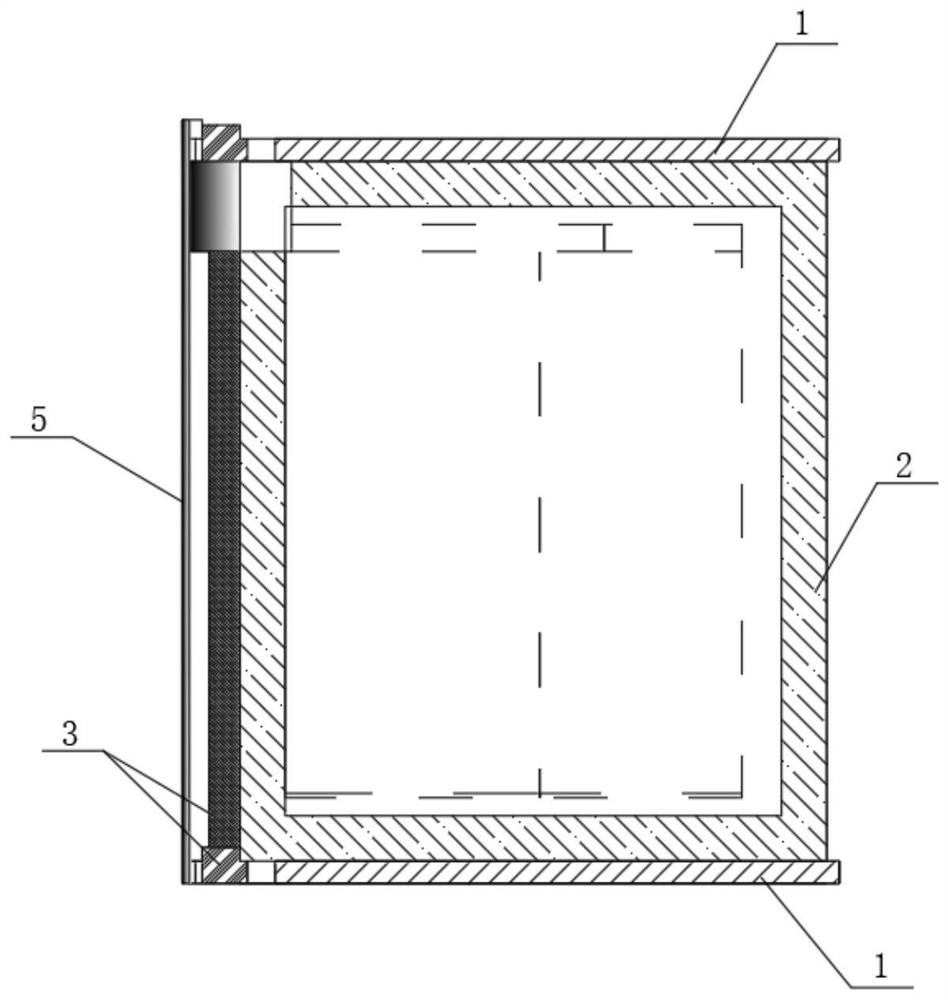

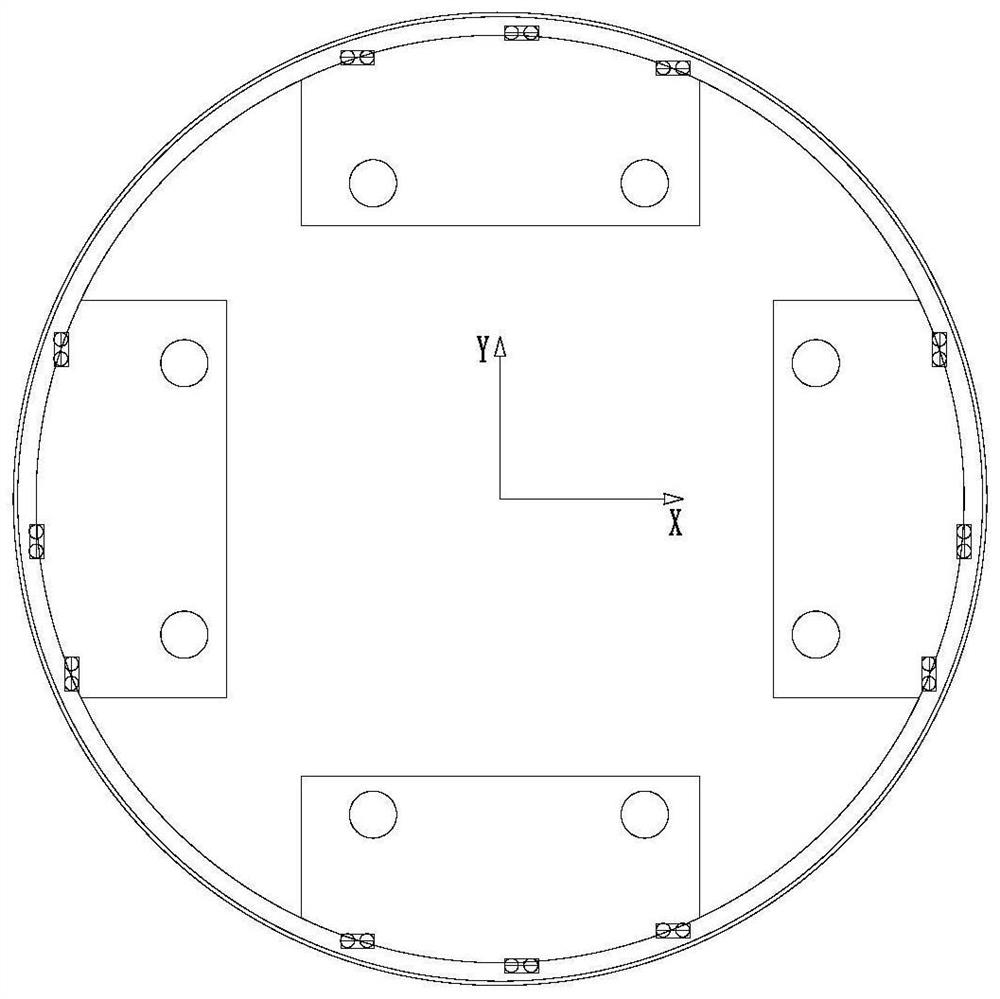

[0022] combine Figure 1 to Figure 4 As shown, a specific implementation of the simulated static test device and method for a columnar cabin wall plate structure provided by the present invention will be described.

[0023] A static test device for simulating a cylindrical cabin wall plate structure, comprising a horizontal plate 1 , a vertical frame 2 , a bulkhead connection structure 3 and a loading mounting seat 4 . The test device is used in the static test process of the wall plate structure of the cylindrical cabin section. The distortion of the force transmission path of the wall plate structure simulation device of the cylindrical cabin section has an adverse effect on the accuracy of the test assessment. The device can be used to simulate the main structure of the entire cabin section The test device meets the strength and stiffness requirements of the main structure and local structure of the entire cabin, and can also simulate the longitudinal and transverse force m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com