Tunnel lining trolley with ventilation pipe capable of smoothly passing through

A technology for lining trolleys and ventilation pipes, applied in tunnel lining, tunnel, shaft lining, etc., can solve problems such as high damage rate, increased air leakage rate, and obstruction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

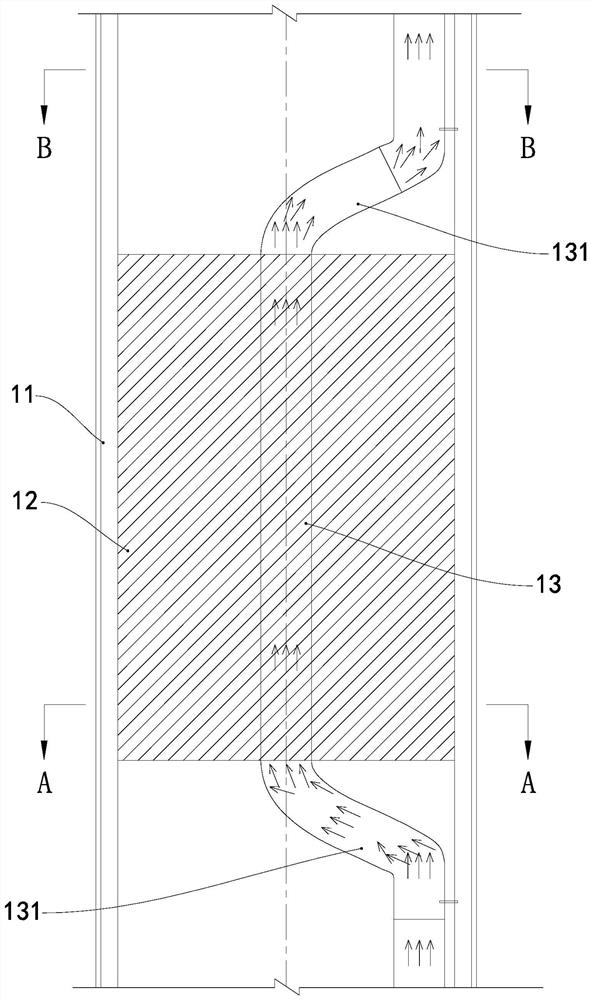

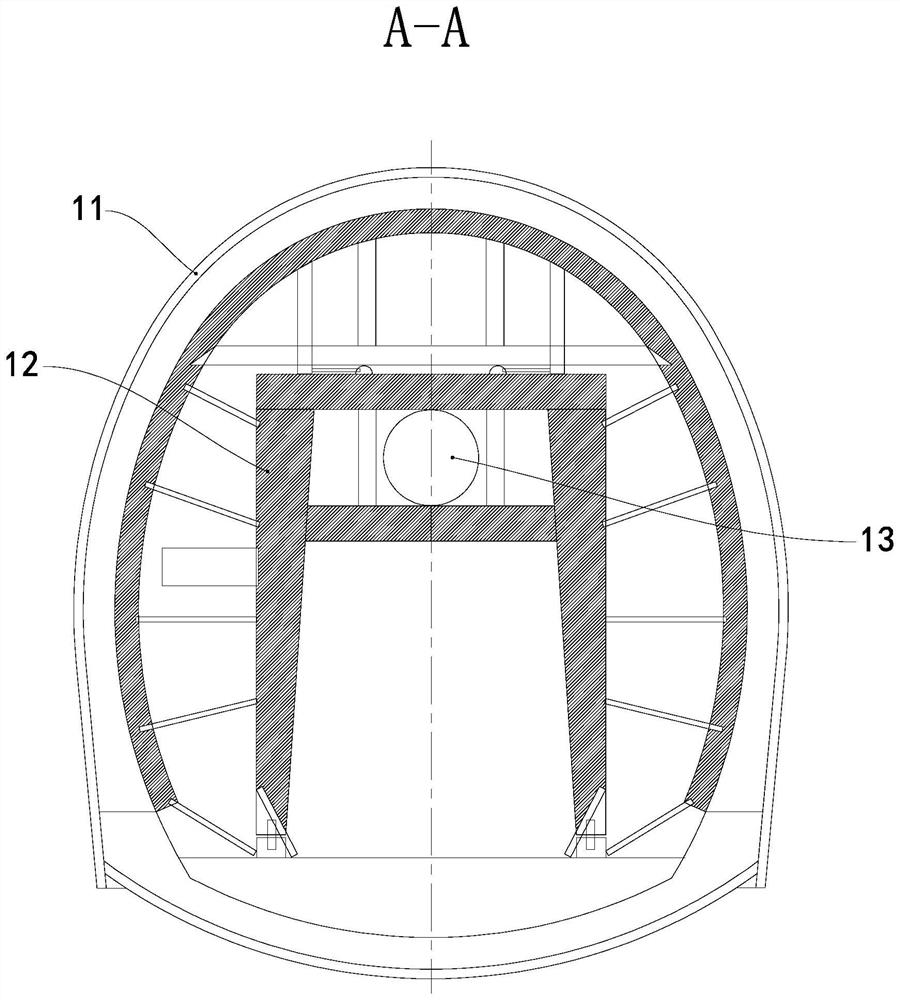

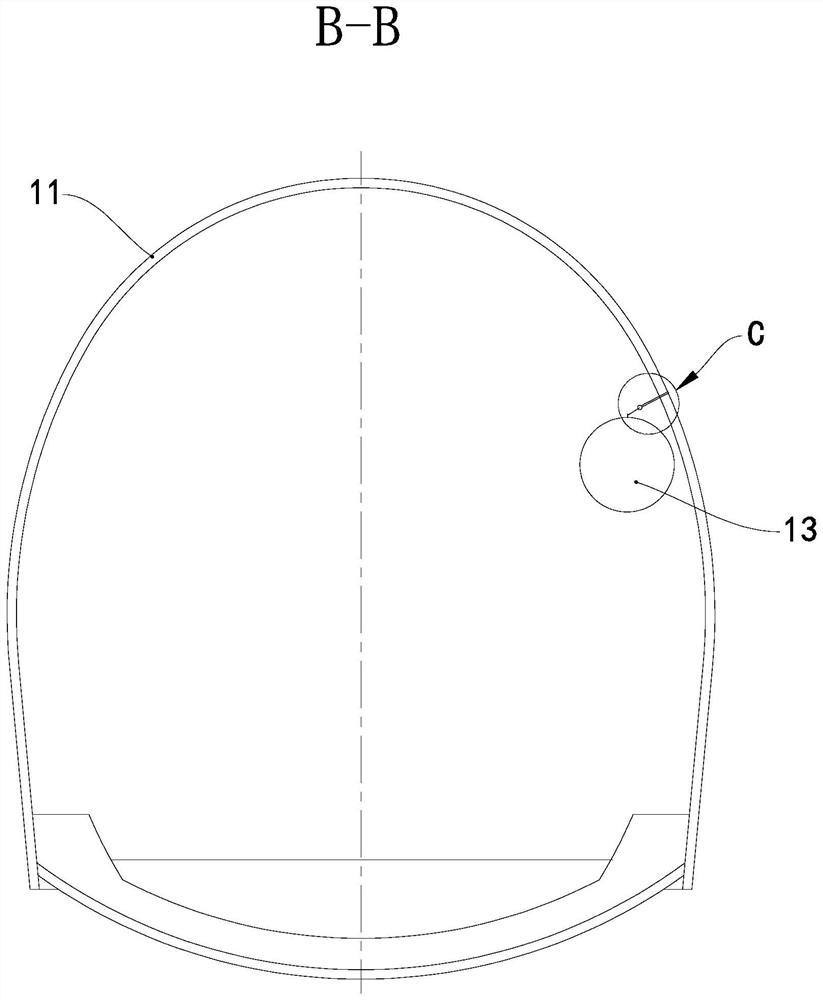

[0037] see Figure 5 to Figure 8 In this embodiment, the tunnel lining trolley includes a side formwork 22, a main door frame 23, and a guide pipe 21 for the ventilation pipe 13 to pass through. The guide pipe 21 is installed on the main door frame 23, and the main door frame 23 is located inside the side formwork 22. , the main door frame 23 is connected with the side mold 22 through the hydraulic screw 24 . Specifically, the guide pipe 21 includes a straight section 211, a first curved section 212 and a second curved section 215, the straight section 211 is installed on the main door frame 23, and the first end of the first curved section 212 and the straight section 211 are away from the second section. A first end of the curved section 215 is connected with a smooth transition, and a first end of the second curved section 215 is connected with a second end of the straight section 211 away from the first curved section 212 through a smooth transition.

[0038] During the c...

no. 2 example

[0045] As an explanation of the second embodiment of the tunnel lining trolley of the present invention, only the differences from the first embodiment of the tunnel lining trolley will be described below.

[0046] see Figure 9 to Figure 13 , the tunnel lining trolley in this embodiment also includes a smooth assembly 3, the smooth assembly 3 includes a plurality of pulleys 31, the plurality of pulleys 31 are arranged in the circumferential direction of the guide pipe 21', and one pulley 31 can rotate around a rotating shaft 32 Turn settings. The rotating shaft 32 is arranged on the pipe wall of the guide pipe 21', and the axis of the rotating shaft 32 is arranged tangentially with the pipe wall of the guide pipe 21', and the outer peripheral wall of each pulley 31 protrudes from the inside of the pipe wall of the guide pipe 21'. The peripheral surface of the hole is arranged such that the peripheral wall of each pulley 31 abuts against the peripheral wall of the ventilation...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com