Intelligent control sand control screen for huff and puff production in sand-producing oil and gas reservoirs and production technology

A technology for sand control screens and oil and gas reservoirs, which is applied in the fields of fluid production, earth-moving drilling, wellbore/well valve devices, etc., and can solve the problems of reduced permeability of sand-retaining media, difficulty in injecting steam, and single sand-retaining precision. Achieve the effect of increasing the validity period of sand control, reducing the blockage and prolonging the blockage period.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

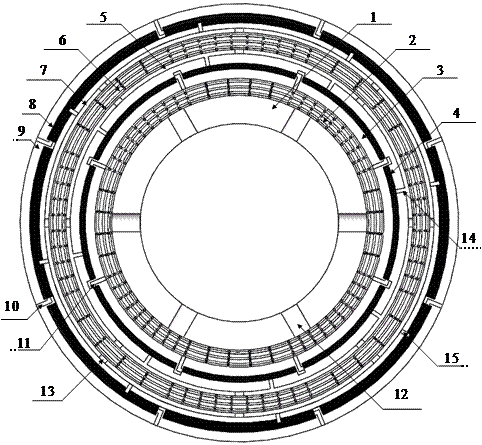

[0044] Figure 1-Figure 17 Embodiment 1 of the present invention is shown.

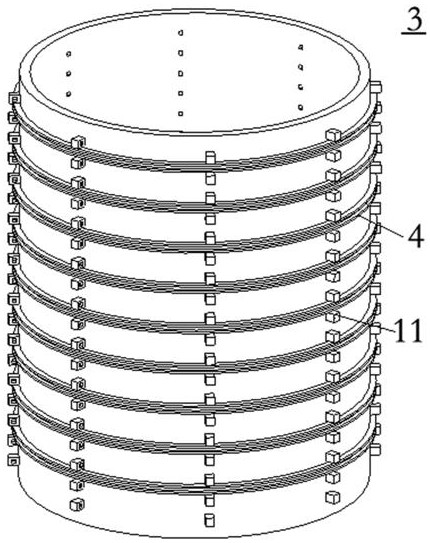

[0045] This embodiment provides an intelligent control sand control screen used for huff and puff production of sand producing oil and gas reservoirs, such as figure 1 As shown, it includes a base pipe 1 , an inner sand retaining medium 2 , an inner diversion guide 3 , an outer sand retaining medium assembly and an outer diversion guide 9 arranged sequentially from inside to outside.

[0046] The material of the base pipe 1 is N80 steel, the base pipe 1 is provided with a diversion hole 12, the diversion hole 12 is circular, the diameter of the diversion hole 12 is 9mm, and the diversion hole The mesh number of 12 is 70 holes / m. The base pipe 1 plays a supporting role, and the guide hole 12 provides an inflow channel for oil and gas.

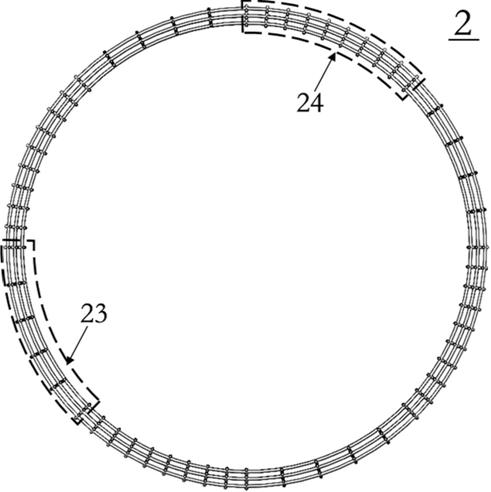

[0047] The inner sand-retaining medium 2 is a metal sintered mesh formed by sintering three layers of 316L stainless steel filter mesh, with a thickness of about 1.2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com