Combined device capable of adjusting discharging amount

A technology of combination device and discharge amount, applied in the field of feeding device, can solve the problems of powder material compaction, inconsistent drying degree of compressed air, inability to effectively control the discharge amount of fluidized materials, etc., and achieve effective control of the discharge amount. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments. The present invention is not limited to this embodiment, and other embodiments may also belong to the scope of the present invention as long as they conform to the gist of the present invention.

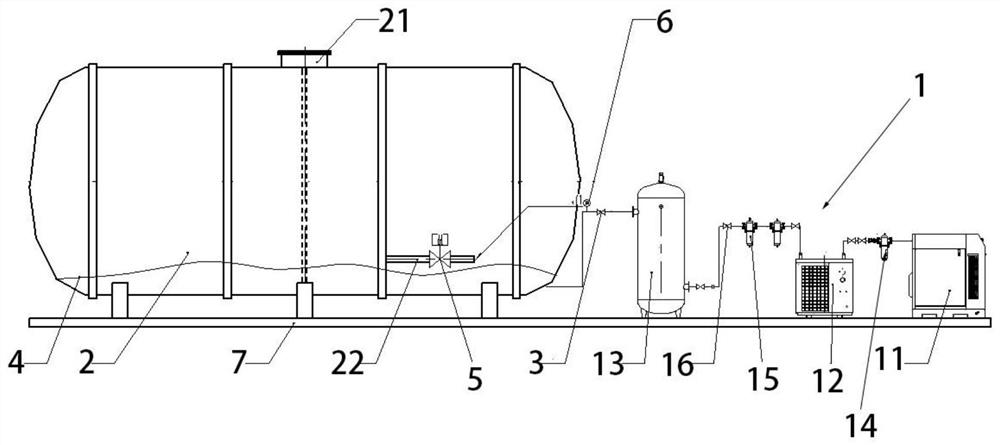

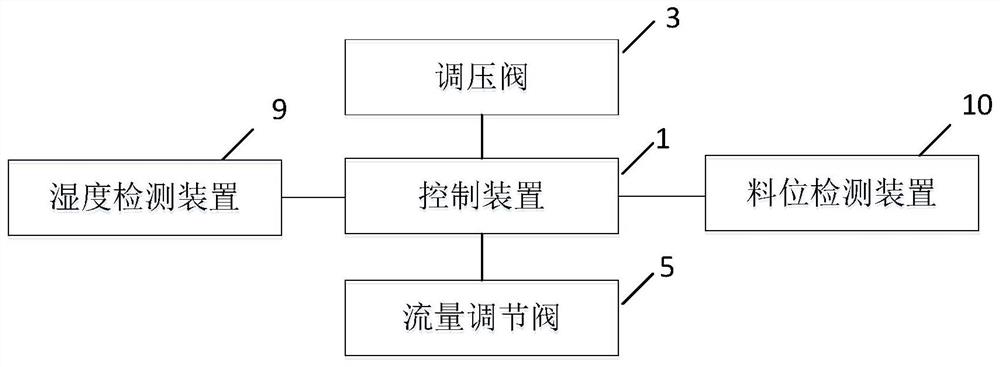

[0030] In a preferred embodiment of the present invention, based on the above-mentioned problems in the prior art, a combined device that can adjust the output is now provided, such as figure 1 and figure 2 shown, including:

[0031] A silo 2, which stores powder materials inside the silo 2. The air inlet of the silo 2 is connected to the air outlet of a dry air source assembly 1 through a pipeline. The dry air source assembly 1 is used to compress the inhaled external air, Filter and dry to obtain dry compressed air, and input the dry compressed air into the silo through the pipeline;

[0032] A pressure regulating valve 3, arranged on the pipeli...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com