Extension system of hydrogen fluoride pre-reactor

A pre-reactor, hydrogen fluoride technology, applied in the chemical field, can solve the problems of sealing failure at the joint, large stress of the cylinder, easy gas obstruction, etc., and achieve the effect of increasing service life, improving utilization rate and increasing space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

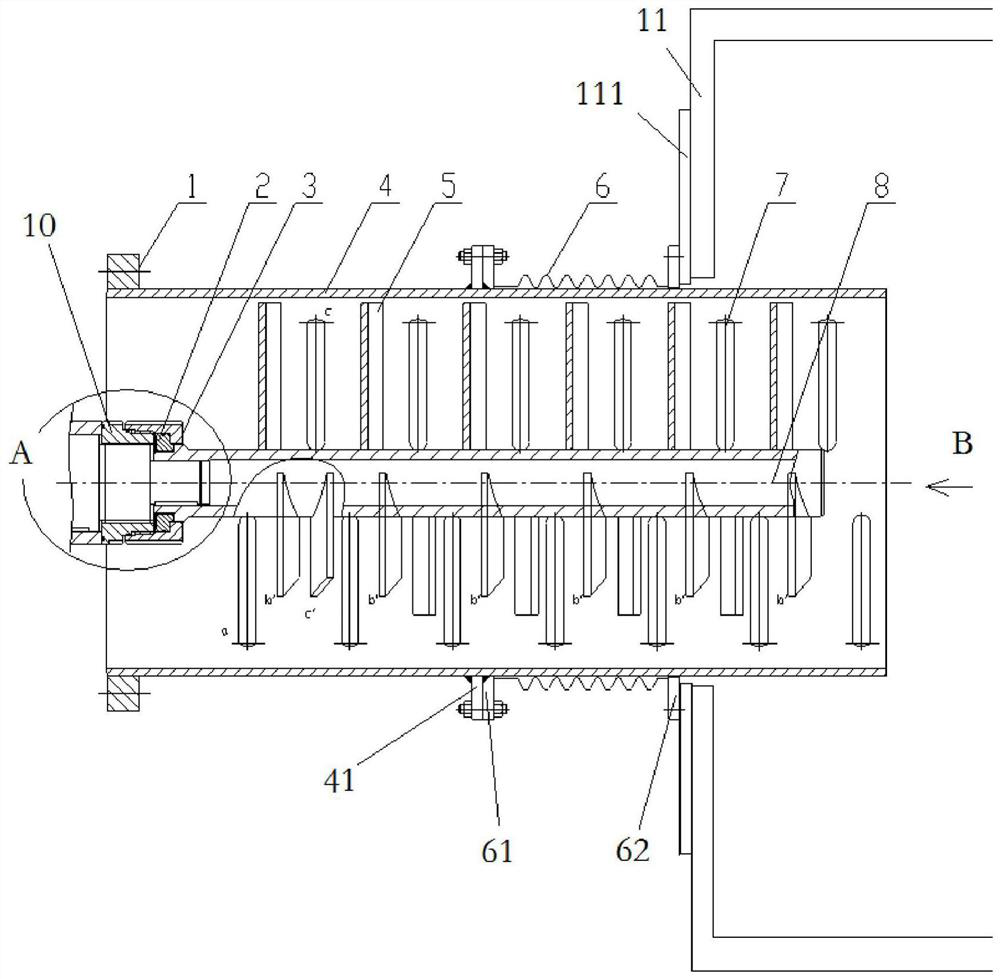

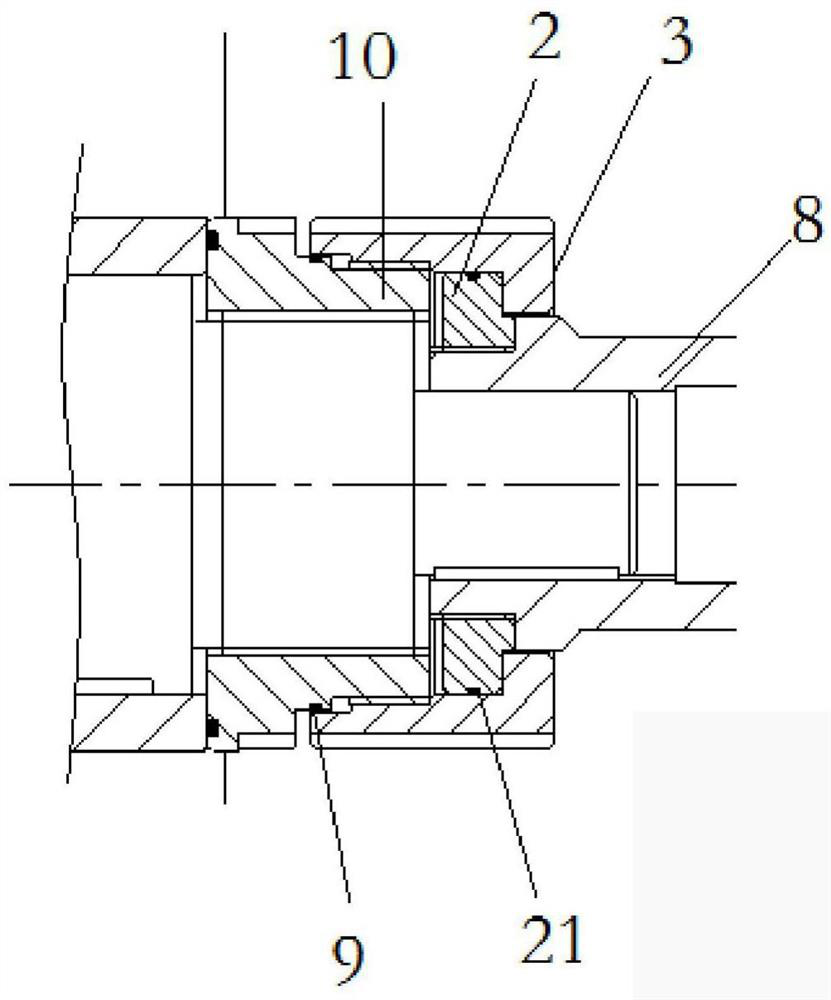

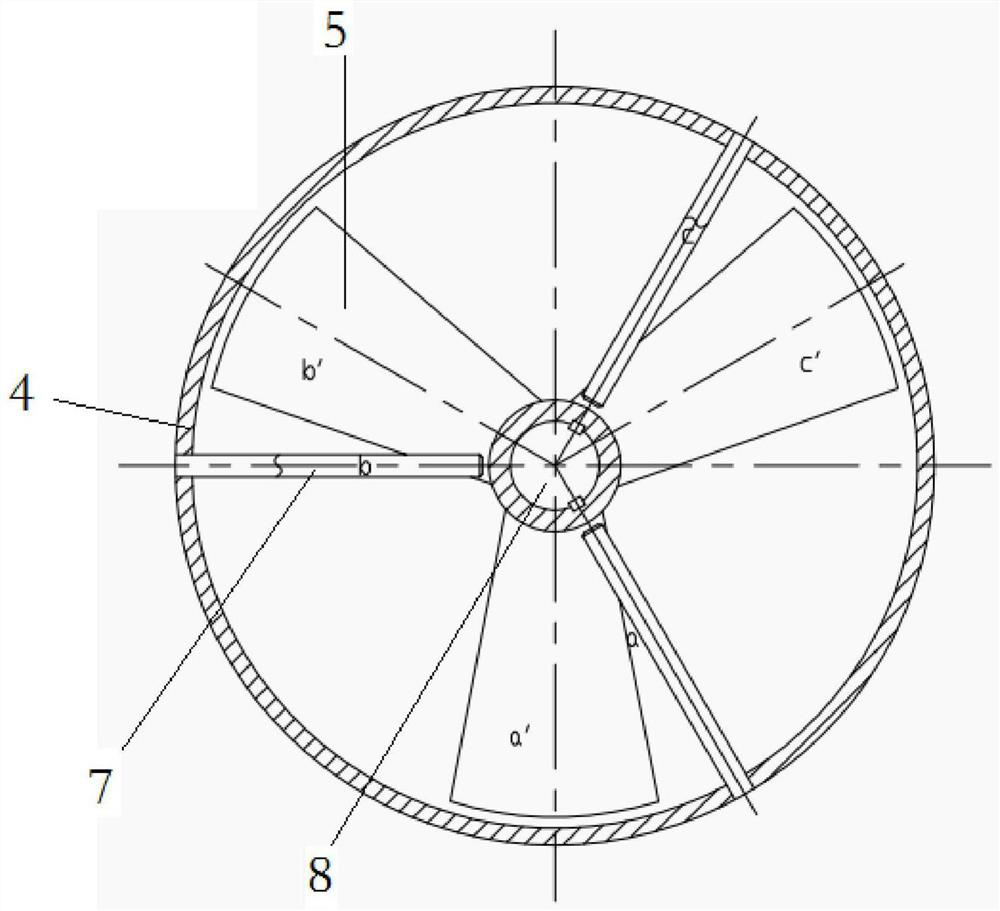

[0025] The present invention is specifically described below in conjunction with accompanying drawing, as shown in the figure, the present invention comprises extension section barrel 4, and the diameter of extension section barrel 4 is greater than the diameter of second stage reaction section (reaction section is in figure 1 The left side of the end flange 1 of the extension section is not shown); the extension section cylinder body is provided with an extension section stirring shaft 8, the extension section stirring shaft 8 is connected with the main shaft 10, and the extension section stirring shaft 8 is provided with paddles 5; every 3 5 paddles are a group, and each paddle of each group is arranged separately along the axial direction of the extension section stirring shaft (that is, each section perpendicular to the extension section stirring shaft axis can only be intercepted to one paddle), from the shaft look to ( figure 1 The center angle of the paddle is 120 degre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com