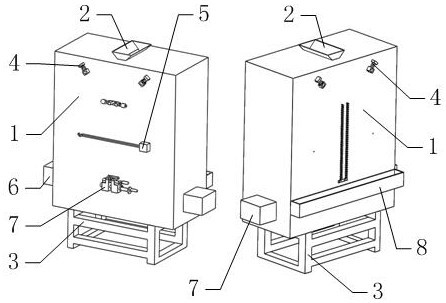

Small-size liquid pressing machine for liquid removal

A small-volume, liquid-removing technology, applied in the field of hydraulic presses, can solve the problems of long diaphragm hydraulic presses, large cross-sections, and complexity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

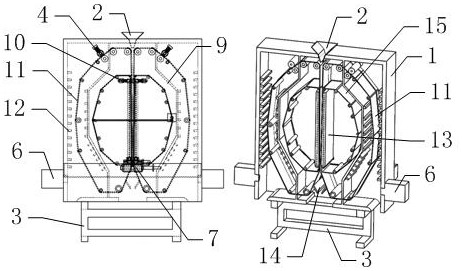

Embodiment approach

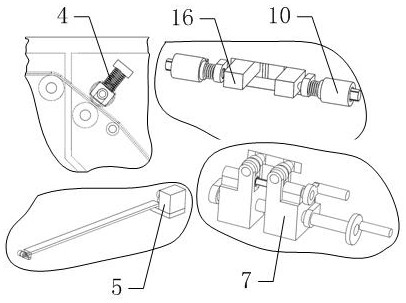

[0079] Embodiment: When using the filter press designed by the present invention, in use, first adjust the spacing and angle between the two filter press plates 13 according to the inspection, the adjustment of the spacing and angle is all adjusted in a small range, and will not affect the two filter plates 13. side of the active belt 15 and filter belt 11; after the adjustment is completed, lock the upper squeeze support mechanism 10 to support the upper end of the filter plate 13; after the adjustment is completed, start to work, first control the motor 50, the motor 50 will drive the fourth gear 48 to rotate, the rotation of the fourth gear 48 will drive the rotation of the third gear 47, the rotation of the third gear 47 will drive the rotation of the corresponding first shaft 43, and the rotation of the first shaft 43 will drive the rotation of the corresponding first shaft 43. A gear 44 rotates, the first gear 44 rotates and drives the corresponding second gear 46 to rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com