A groove-type inclined shaft, tunnel structure and design method for preventing sand inrush during operation period

A design method and groove-type technology, applied in tunnels, design optimization/simulation, computer-aided design, etc., can solve problems such as endangering the safety of tunnel operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

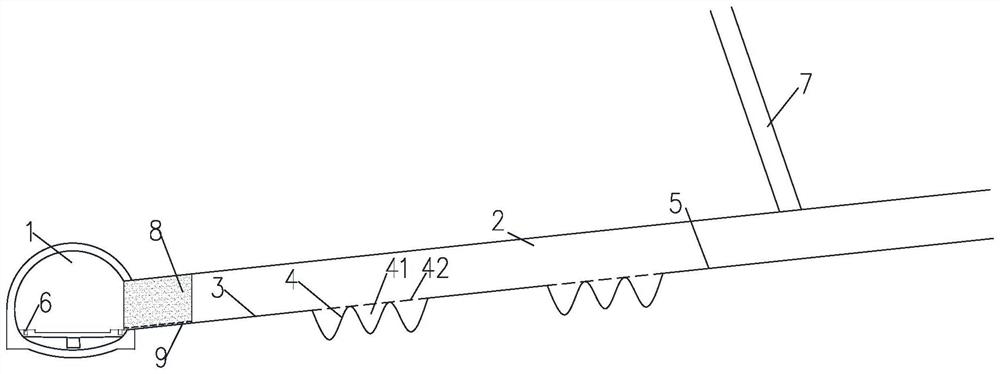

[0045] Such as figure 1 , 2 , 4 and 5, a groove-type inclined well for preventing sand inrush during the operation period described in this embodiment, the inclined well passes through the water-rich fault 7, including the inclined well channel 2, and the downstream of the inclined well channel 2 A plugging structure 8 is provided at the end, and a groove 41 for accommodating sand blasting is provided at the lower part of the well wall of the inclined shaft channel 2 .

[0046] On the basis of the above, in a further preferred manner, the groove 41 is in a wave shape along the longitudinal direction of the inclined shaft channel 2, so that the groove is not easy to collapse.

[0047] On the basis of the above, in a further preferred manner, the top of the groove 41 is covered with a steel wire mesh 42 to prevent larger stones from entering the groove 41 .

[0048] On the basis of the above, in a further preferred manner, an early warning device is provided in the inclined sh...

Embodiment 2

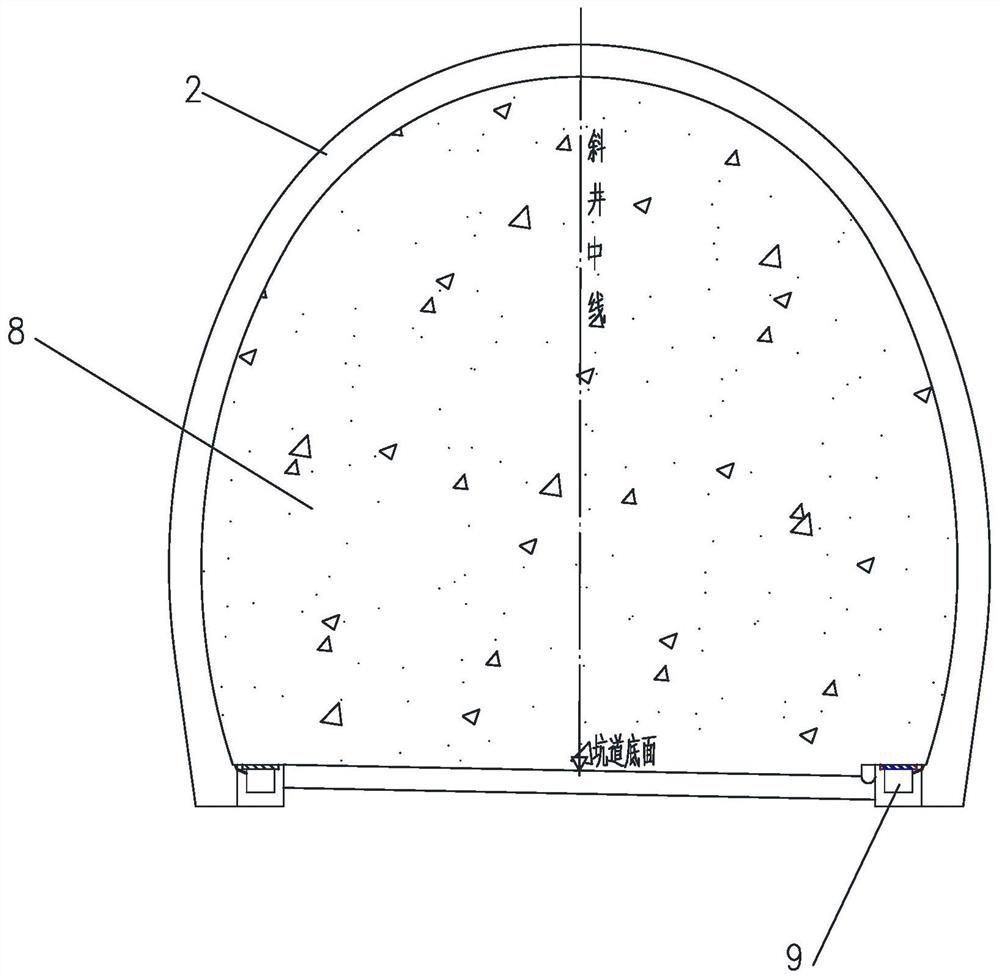

[0056] Such as figure 1 , 2 , 4 and 5, a kind of tunnel structure described in the present embodiment includes the groove type inclined shaft for preventing sand inrush during the operation period described in the positive tunnel 1 and embodiment 1, and the plugging structure 8 is arranged in The inclined shaft channel 2 is close to the end of the main hole 1 , and the bottom of the sealing structure 8 is provided with a drainage channel 9 , and the drainage channel 9 communicates the inclined shaft channel 2 and the main hole 1 .

[0057] On the basis of the above, in a further preferred manner, a drainage ditch is arranged in the main hole 1, and the drainage channel 9 communicates with the drainage ditch.

[0058] Specifically, the drainage ditch is the side ditch 6 of the main hole or the central gutter.

[0059] The beneficial effects of this embodiment: use the groove 41 to collect sand, reduce the total kinetic energy of sand in the inclined shaft channel 2, prevent t...

Embodiment 3

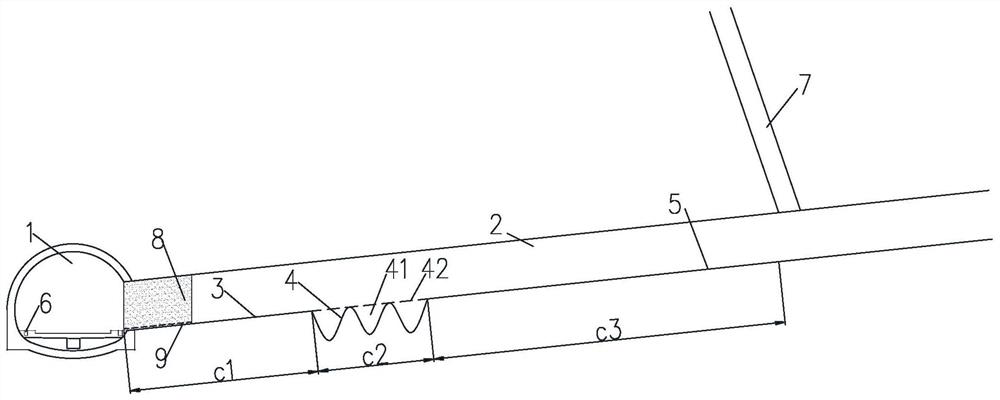

[0061] Such as Figure 1-Figure 5 As shown, a design method described in this embodiment is used to calculate the width s of the groove 41 and the length C of the groove segment 4 2 , specifically: Contains the following steps:

[0062] S1: Establish a deviated well design model based on the grooved inclined well for sand inrush prevention during the operation period described in Embodiment 1 or 2, and make the deviated well design model satisfy: input drainage section 3 flow rate b 1 and flow rate b of sand gushing section 5 3 Get the length C of groove segment 4 2 and the operational relationship between the width s of the groove 41;

[0063] S2: The width s of the groove 41 is proposed according to the maximum lateral dimension A of the bottom of the cross section of the inclined shaft channel 2, s≤A, based on the width s of the groove 41 and the length C of the groove segment 4 2 and the operational relationship between the width s of the groove 41, the length C of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com