Planet wheel roller pin press-fitting machine

A planetary wheel and press machine technology, applied in the field of automation, can solve problems such as low work efficiency, missing needle rollers, time-consuming and laborious assembly, etc., and achieve the effect of solving low efficiency, improving efficiency and ensuring assembly quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0052] Below in conjunction with accompanying drawing this embodiment is described in detail:

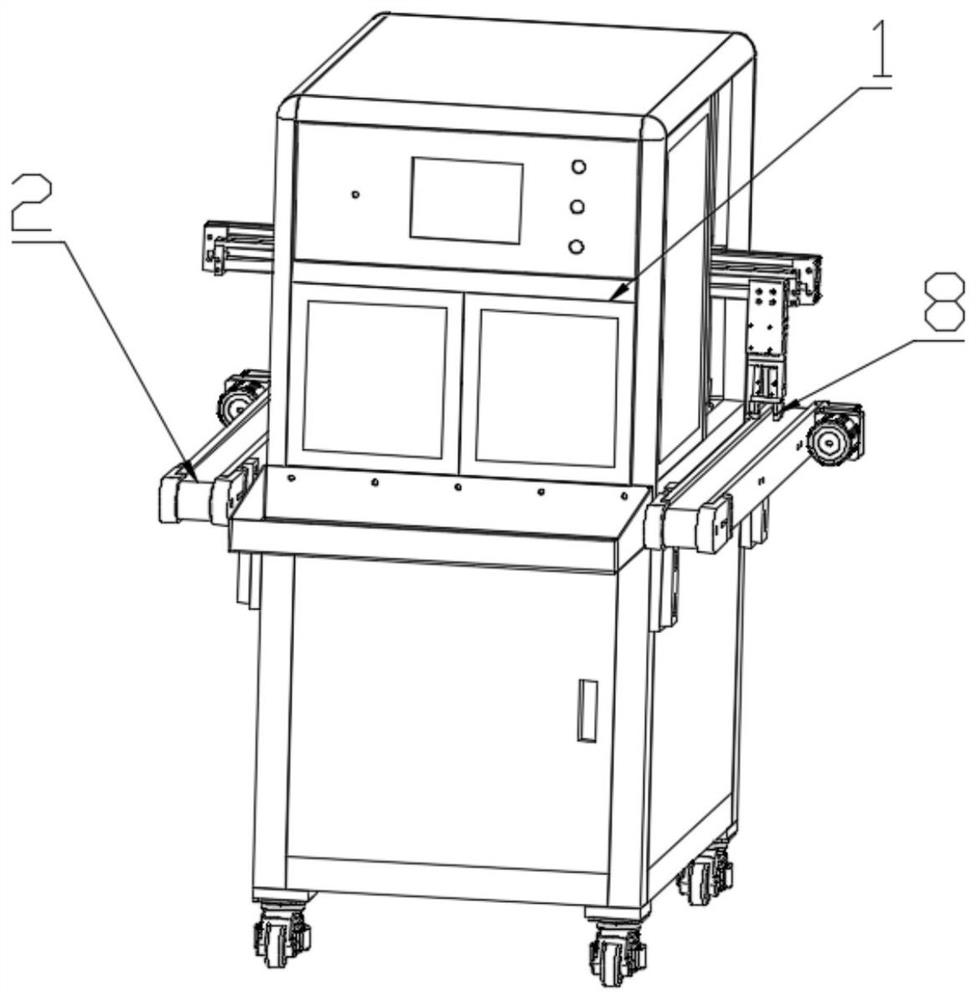

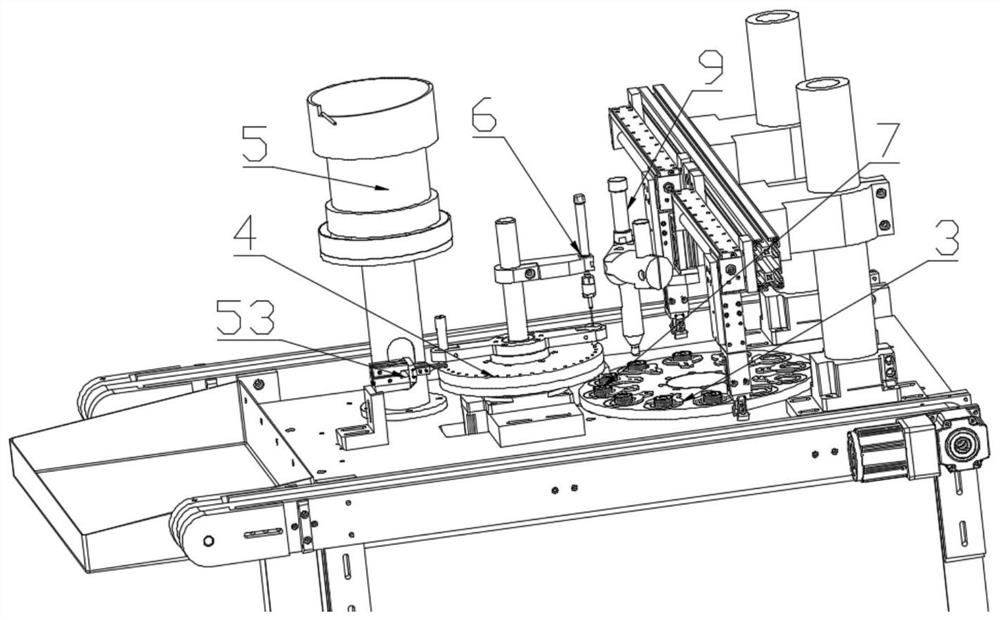

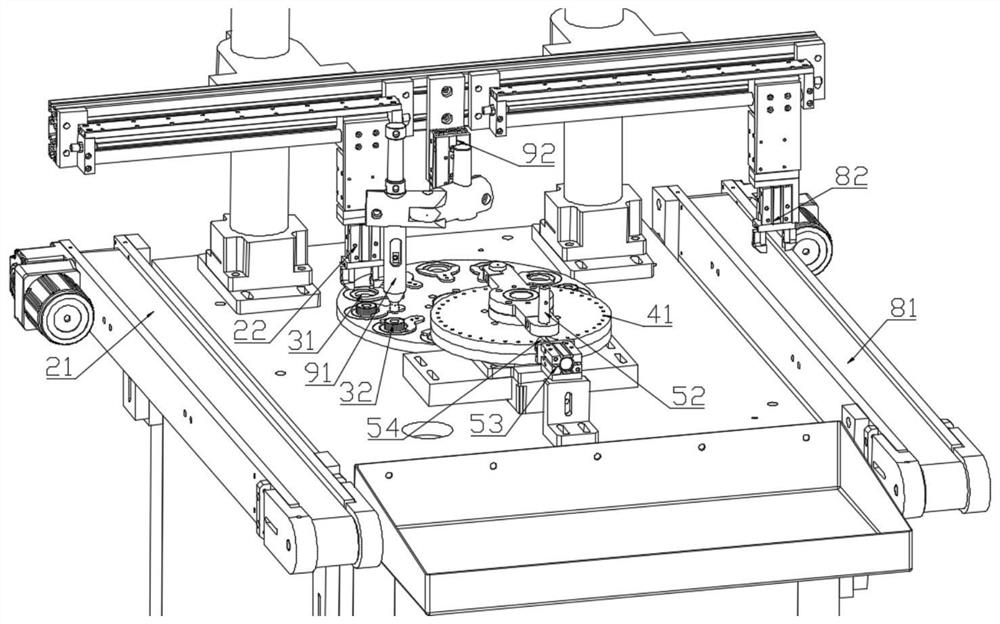

[0053] The present invention provides such Figure 1-8 A planetary wheel needle roller press machine shown includes a frame 1, and also includes:

[0054] The planetary wheel charging device includes a planetary wheel feeding mechanism 2, and a planetary wheel tray structure 3 rotatably arranged on the frame 1, and a plurality of fixed grooves 31 are arranged at annular intervals on the planetary wheel tray structure 3. The wheel feeding mechanism 2 is used to place the planetary wheel workpiece 32 to be assembled in the fixed groove 31;

[0055] The needle roller charging device includes a needle roller tray structure 4 that is rotatably arranged on the frame 1, and a number of minute needle holes 41 arranged at annular intervals on the needle roller tray structure 4, and is used to place needle roller workpieces 42 The needle roller feeding mechanism 5 placed in the minute needl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com