Light emitting diode driving system

A technology of light-emitting diodes and driving systems, applied in electrical components and other directions, can solve the problems of high failure rate, unsatisfactory stability and reliability, low flexibility of use, etc., to improve the voltage value, improve the control flexibility, The effect of improving stability and reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

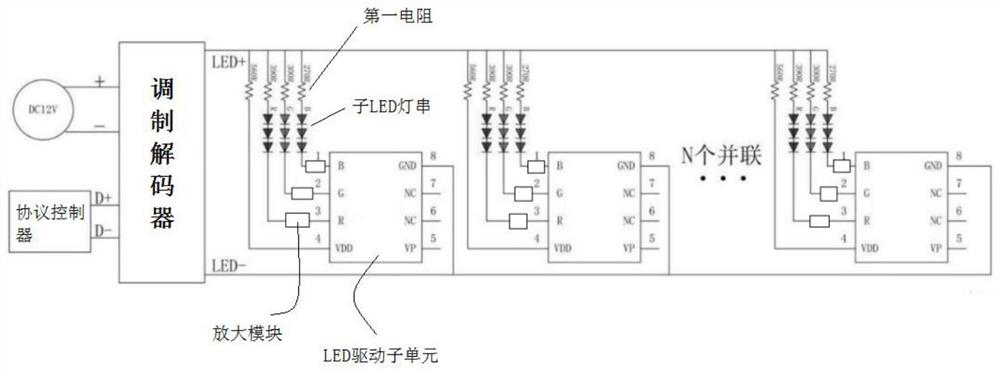

[0017] Embodiment 1: a kind of LED driving system, such as figure 1 As shown, it includes a modulation decoder, the input end of the modulation decoder is connected with a first power supply and a protocol controller; the output end of the modulation decoder is connected in parallel with a plurality of LED driving subunits, and the LED driving subunit includes a driving subchip, and the driving subunit The input terminal of the chip is connected with multiple color sub-wires, on which there are sub-LED light strings and first resistors, and the other end of the color sub-wires is connected to the positive lead-out wire of the modulation decoder; the ground terminal of the LED driving sub-unit is connected to the The negative lead wire of the modulation decoder is connected. The invention controls the LED light strings on each color sub-line through multiple driving sub-chips, which greatly improves the control flexibility of the LED light strings, and the multiple LED light st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com