Hydraulic pulsation fatigue test device for axle

A fatigue test and hydraulic technology, applied in the direction of measuring device, vehicle test, vehicle suspension/shock absorbing mechanism test, etc., to achieve the effect of improving the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

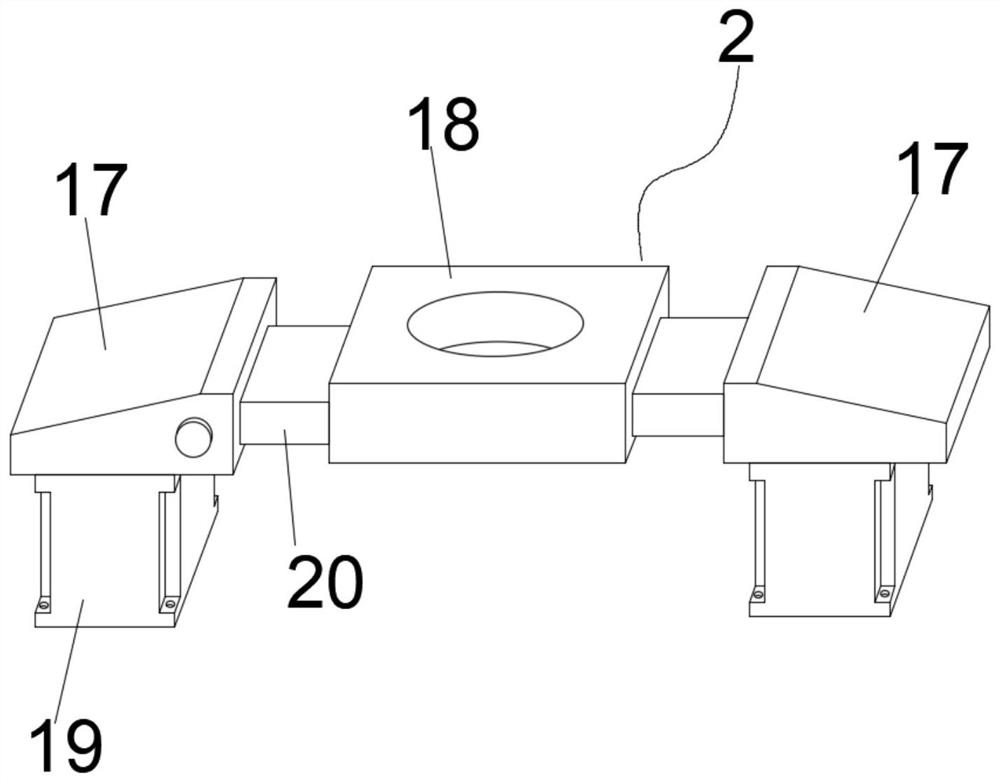

[0029] The gantry fixed frame 2 comprises a fixed foot frame 17 and a docking sleeve plate 18, and a circular notch runs through the inner middle part of the butt joint sleeve plate 18. The number of the fixed foot frame 17 is two groups, and the fixed foot frame 17 is movably installed on the butt joint. At the two ends of the cover plate 18, the second expansion plate 20 is sleeved between the fixed foot frame 17 and the butt joint cover plate 18, and the bottom of the fixed foot frame 17 is fixedly equipped with a support block 19. By using the setting of the second expansion plate 20, the When the fatigue test device is used for testing different types of vehicle axles, the fixed foot frame 17 can be pulled, and the second telescopic plate 20 can be extracted from between the fixed foot frame 17 and the docking sleeve plate 18, thereby adjusting the use of the gantry fixed frame 2 length, so that the gantry fixing frame 2 can be adjusted accordingly according to the length ...

Embodiment 2

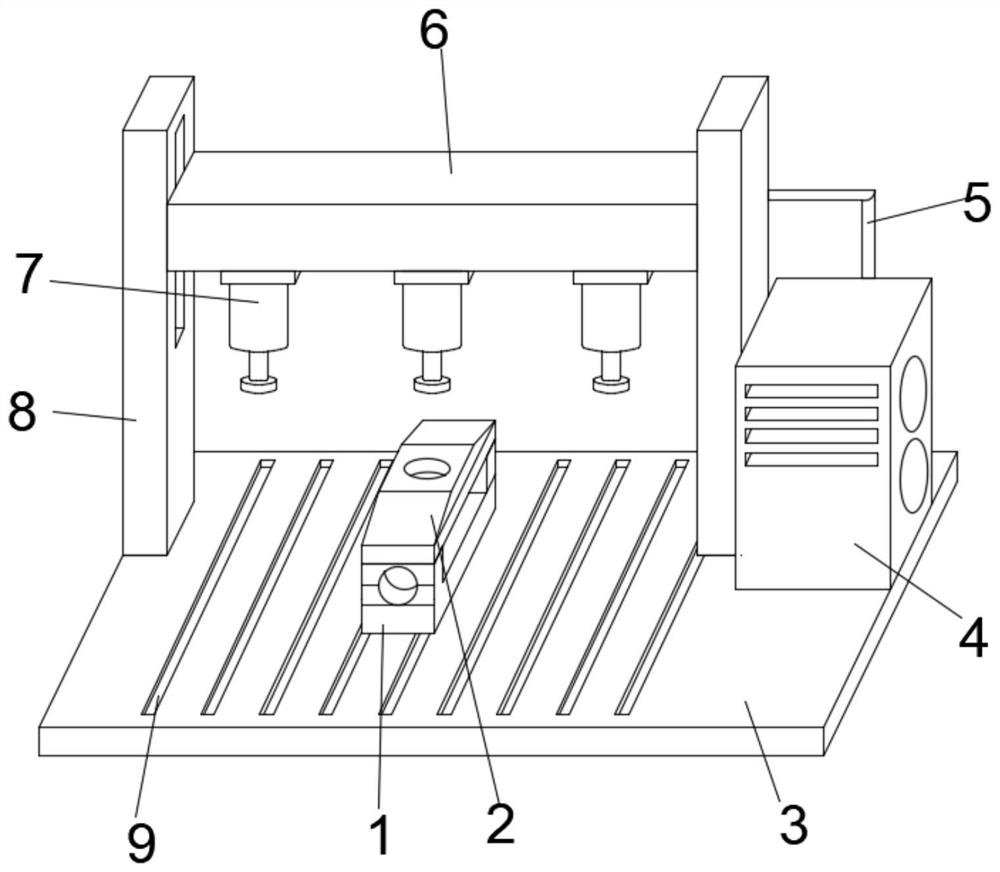

[0032]The two sides of the pulse head 7 are provided with a gantry 8, and the pulse head 7 and the gantry 8 are movably connected by the lifting frame 6. The outer surface of the side of the gantry 8 is provided with a lifting chute, and the gantry 8 is driven by a hydraulic method. frame 6, so that the lifting frame 6 can drive the pulse head 7 to move up and down, so that the pulse head 7 can be inserted into the circular slot of the docking sleeve plate 18 after moving, so that it is convenient to carry out hydraulic pulsation fatigue test on the installed axle structure .

[0033] A hydraulic cylinder 4 is installed on one side of the gantry 8, and an oil pipe 5 is arranged between the hydraulic cylinder 4 and the pulse head 7. The hydraulic cylinder 4 is used to provide power for the pulse head 7 through the oil pipe 5, so that the pulse head 7 moves downward, and the vehicle Bridge structure for test operation.

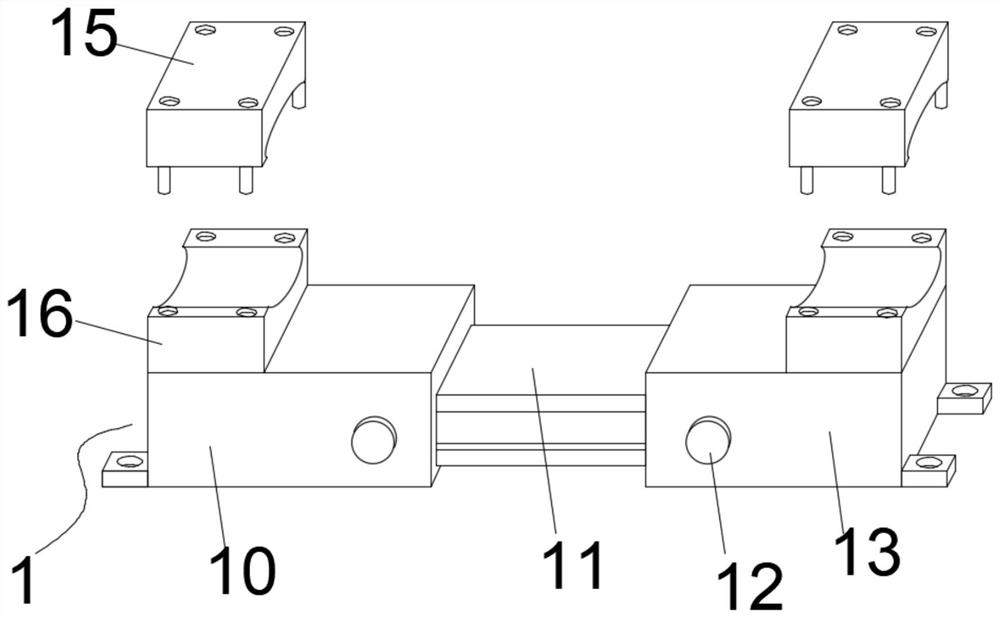

[0034] The upper part of the shaft clamp 16 is fixedly sl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com