Expressway bridge medial strip anti-falling safety facility

A technology for median strips and highways, applied in bridge construction, bridges, bridge materials, etc., can solve problems such as bridge falling accidents, and achieve high safety, stable connection, and convenient construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

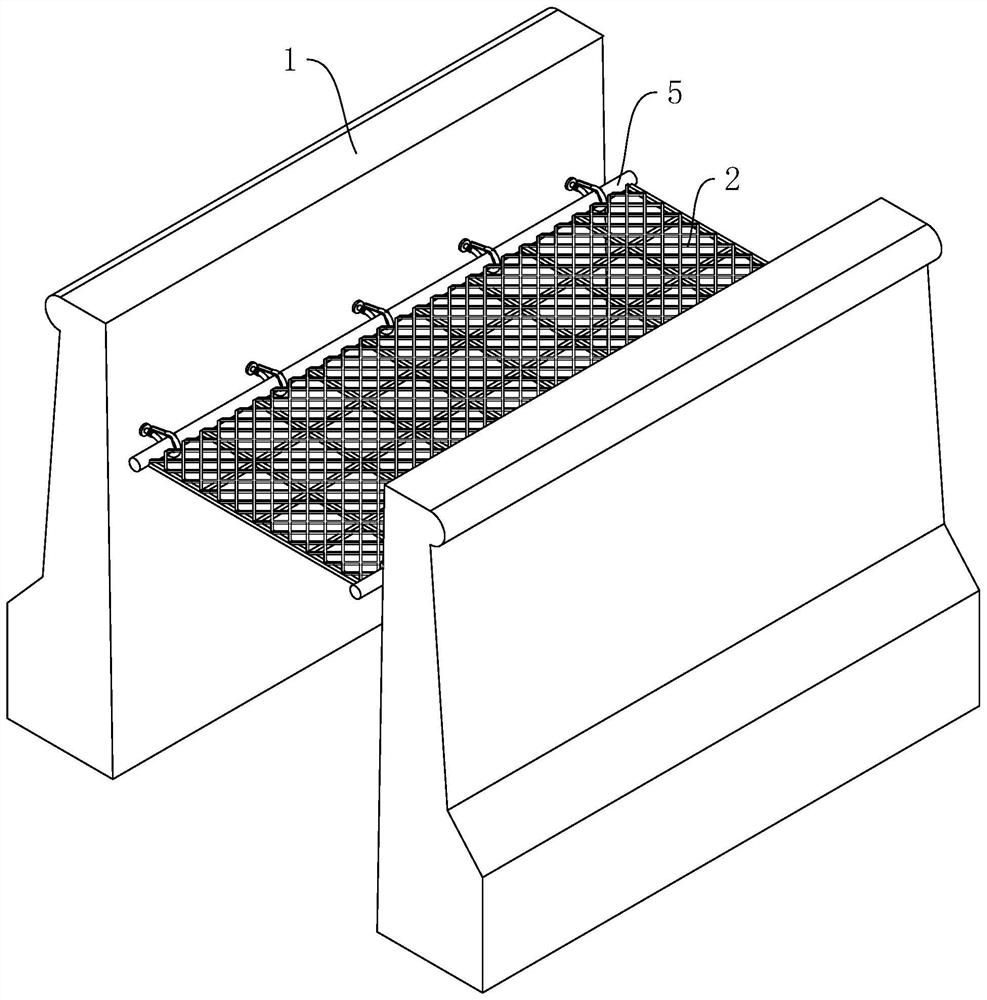

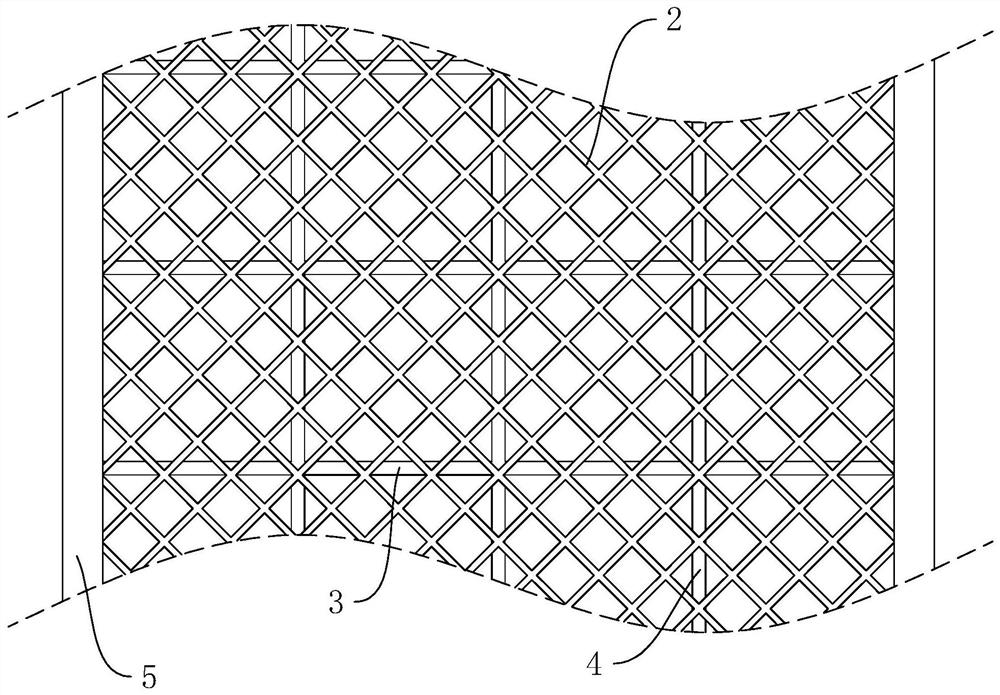

[0042] refer to figure 1 and figure 2 A kind of anti-falling safety facility for the central divider of an expressway bridge comprises two oppositely arranged concrete guardrails 1, the two concrete guardrails 1 respectively belong to two adjacent bridges, and the central divider is between the two concrete guardrails 1; A safety protection net 2 is arranged horizontally between the two concrete guardrails 1, and a plurality of transverse reinforcement ropes 3 and a plurality of longitudinal reinforcement ropes 4 are arranged horizontally below the safety protection net 2, and the transverse reinforcement ropes 3 are all perpendicular to the two concrete guardrails. 1 the opposite side walls, the longitudinal reinforcement ropes 4 are parallel to the opposite side walls of the two concrete guardrails 1, all the transverse reinforcement ropes 3 and all the longitudinal reinforcement ropes 4 are fixed to each other, the opposite sides of the safety protection net 2 and all Bot...

Embodiment 2

[0049] refer to Figure 4 , The difference from Embodiment 1 is that there are gaps between the transverse reinforcement rope 3 and the safety protection net 2, and between the longitudinal reinforcement rope 4 and the safety protection net 2. When the safety protection net 2 is under pressure, it first produces a certain degree of deformation to offset a part of the pressure. The transverse reinforcement rope 3 and the longitudinal reinforcement rope 4 provide support for the safety protection net 2, which improves the strength of the transverse reinforcement rope 3 and the longitudinal reinforcement rope. 4 service life.

Embodiment 3

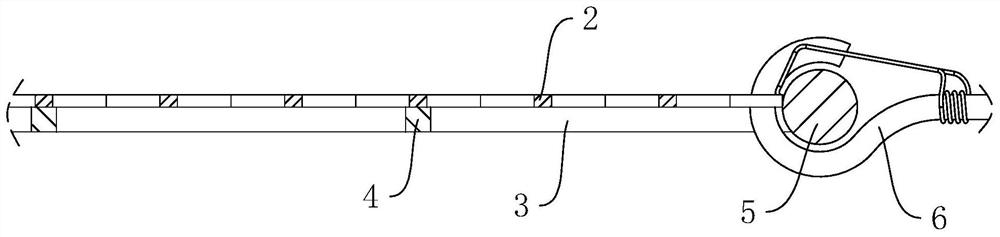

[0051] refer to Figure 5 and Figure 6 , The difference from Embodiment 1 is that each hook 6 is provided with an anti-unhook mechanism 8 for preventing the thickened side rope 5 from detaching from the hook 6 . The top of the hook end 62 is provided with a vertically arranged pressing groove 621, and the bottom of the pressing groove 621 is provided with an accommodating groove 622, and the opposite sides of the accommodating groove 622 are provided with horizontal sliding holes; The bent portion 71 is hollow in the middle, and the two sides of the bent portion 71 are respectively located on opposite sides of the hook end 62 , and the openings of the two sliding holes are respectively located inside the two sides of the bent portion 71 .

[0052] refer to Figure 5 and Figure 6 The anti-decoupling mechanism 8 includes a pull column 81 slidably connected in the pressing groove 621, two connecting rods 82 hinged at the bottom end of the pull column 81 and located in the re...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com