Electric driving system of double-system petroleum drilling machine

An electric drive system and drive system technology, applied in control systems, rotary drilling rigs, percussion drilling, etc., can solve problems such as high cost, low degree of automation, and narrow speed regulation range, and achieve low maintenance costs and guarantee The effect of safe drilling operation and excellent control performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation manners of the present invention will now be described with reference to the accompanying drawings.

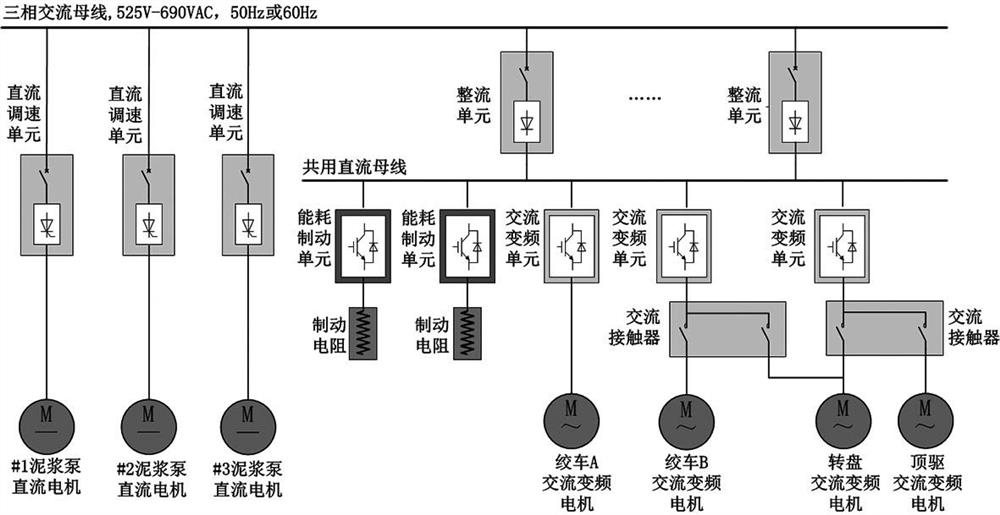

[0031] In this example, if figure 1 As shown, a dual-system oil drilling rig electric drive system includes a three-phase AC bus, a DC drive system and an AC drive system; the output terminals of the three-wire AC bus are connected to the DC drive system and the AC drive system respectively; the AC power voltage output by the three-phase AC bus 525VAC-690VAC, frequency 50Hz or 60Hz.

[0032] The DC drive system includes a plurality of DC speed regulation units, the output of each DC speed regulation unit is connected to the DC motor of the mud pump; the DC speed regulation unit is a thyristor, and the thyristor DC speed regulation unit rectifies 525VAC-690VAC three-phase AC power It is an adjustable DC power supply, which drives...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com