Ventilation equipment for subway construction

A technology for ventilation equipment and subways, which is applied to mining equipment, mechanical equipment, mine/tunnel ventilation, etc. It can solve the problem of automatic filter cleaning and other problems, and achieve the effect of improving the cleaning effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

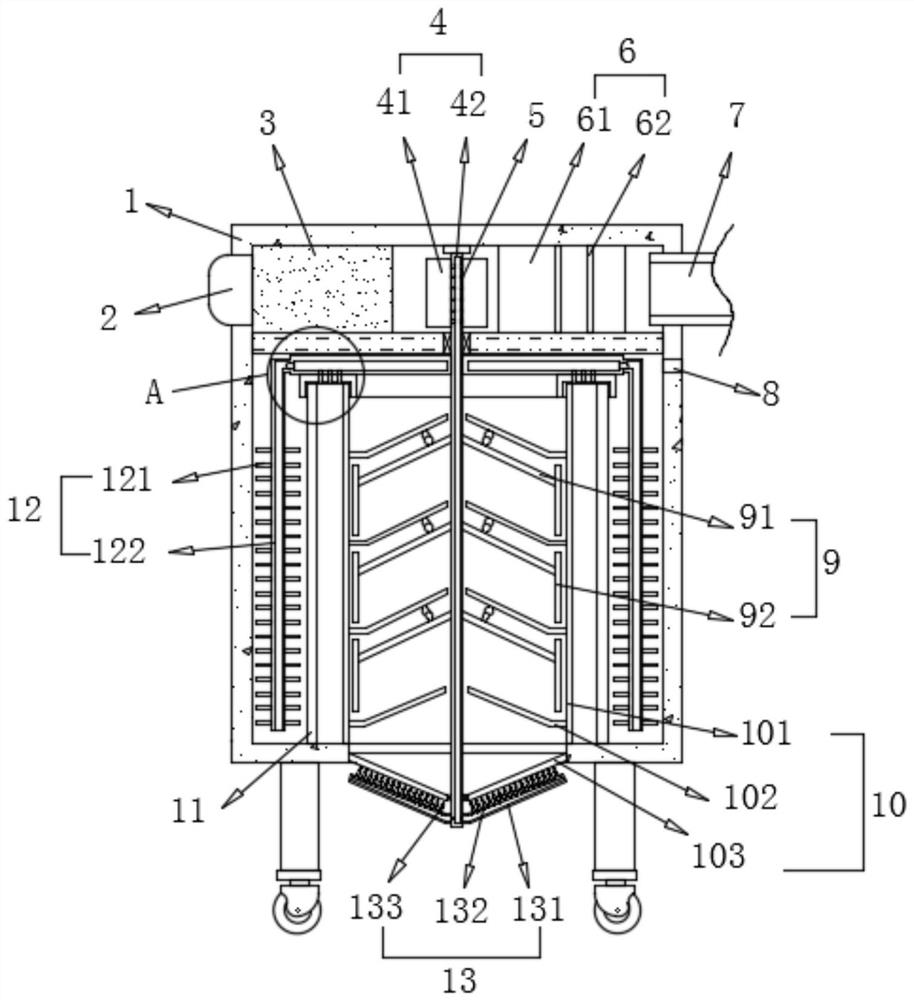

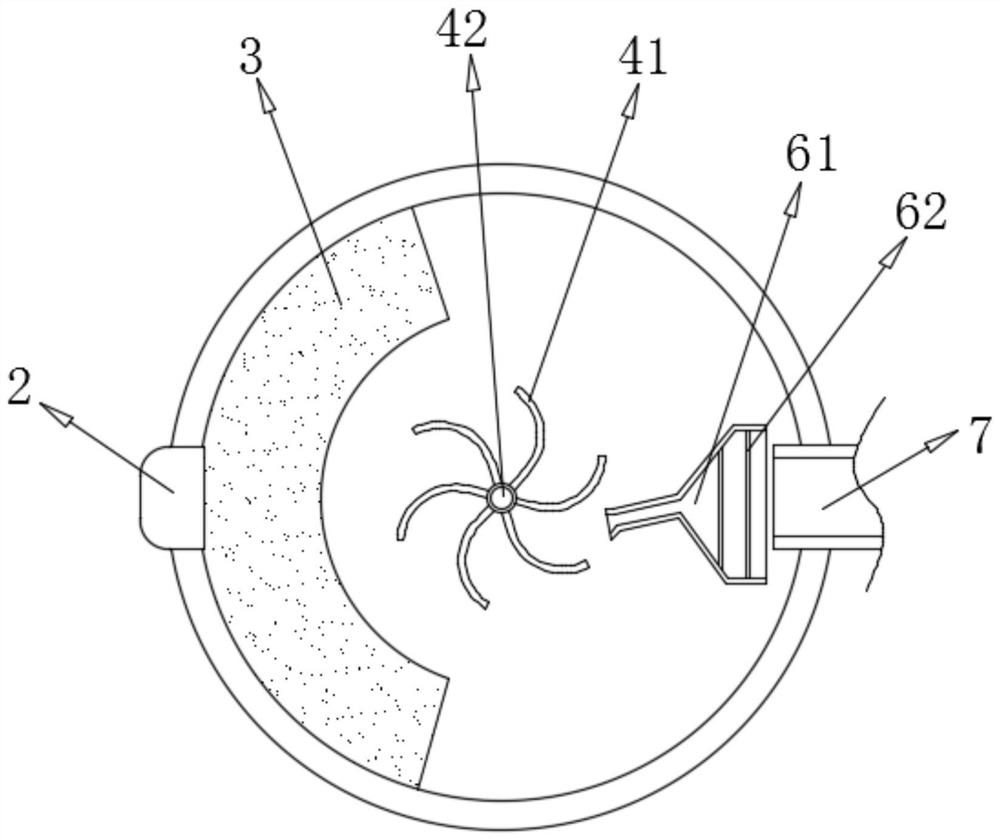

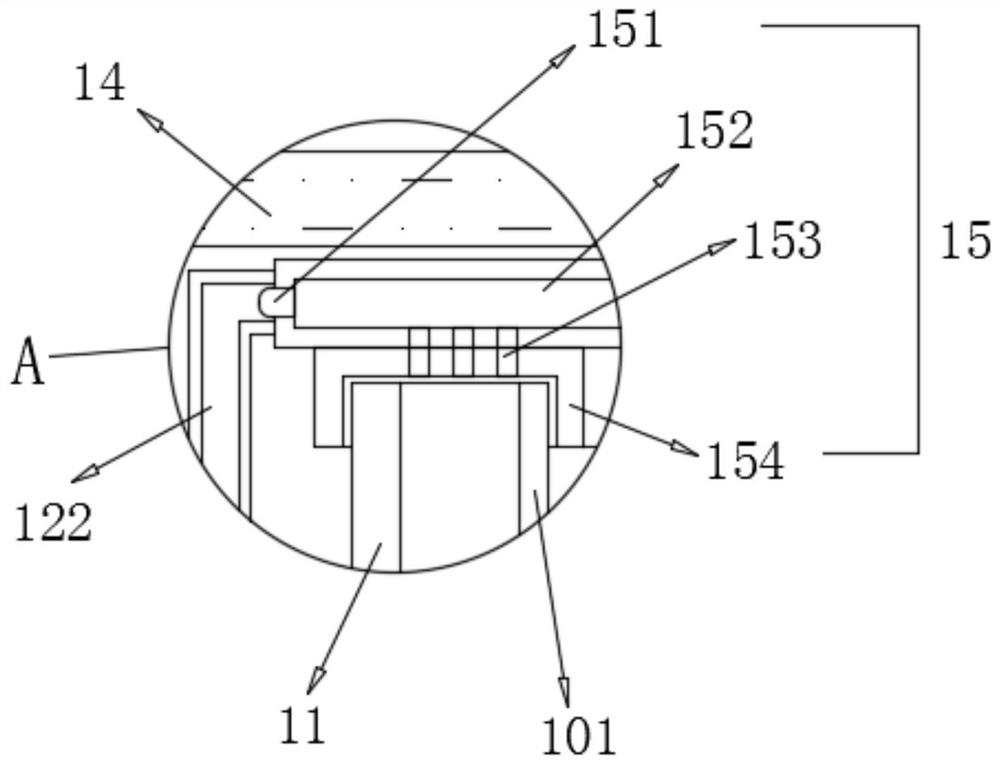

[0035] refer to Figure 1-4 , a subway construction ventilation equipment, including a box 1, a first exhaust component 2 is installed on one side of the box 1, and an air inlet component 7 is installed on the other side of the box 1, and a partition is installed on the inner wall of the box 1 plate 14, and one end of the first air exhaust part 2 and the air inlet part 7 are all located on the same side of the partition 14, and one side of the box body 1 is equipped with supporting legs, and also includes a drive mechanism 4 for injecting with the air inlet part 7 The airflow rotates; the drive mechanism 4 includes a rotating part 42 installed on the inner wall of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com