Pressure-resistant structure suitable for deep diving and floating and diving method of pressure-resistant structure

A pressure-resistant structure and pressure-resistant shell technology, which is applied to underwater ships, special-purpose vessels, and underwater operating equipment, can solve the problems of large wall thickness and difficult processing of pressure-resistant shells, so as to increase the compressive strength, increase The effect of deep dive and high generalization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The specific implementation manner of the present invention will be described below in conjunction with the accompanying drawings.

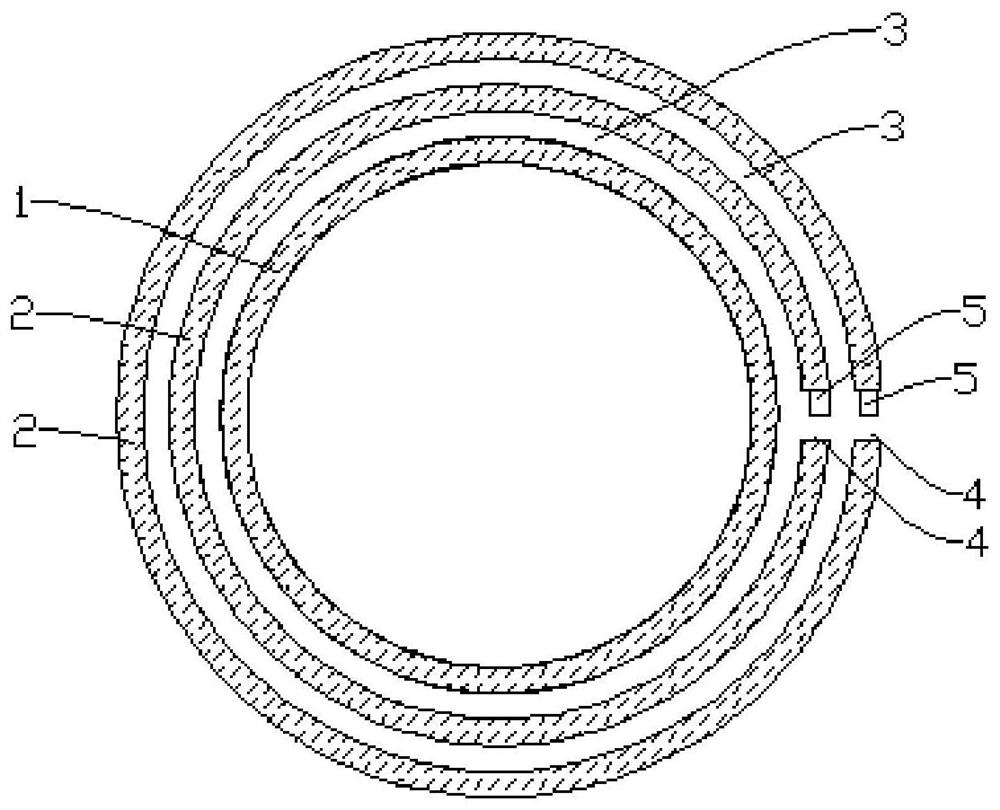

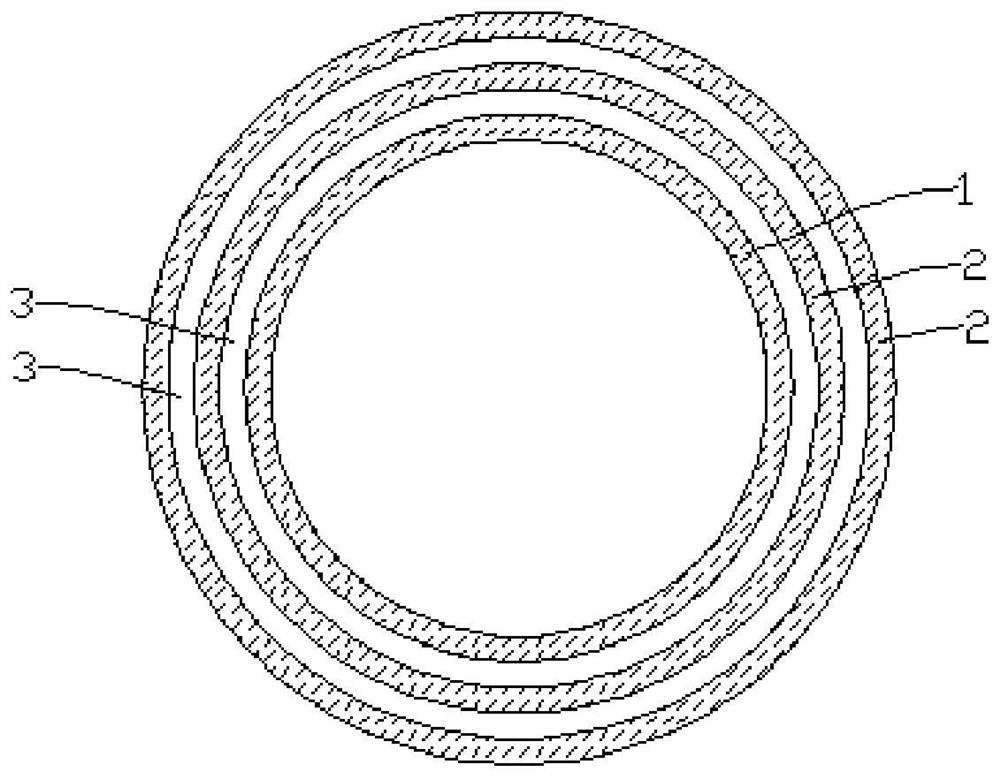

[0031] Such as figure 1 and figure 2 In the shown embodiment, it mainly includes a central pressure-resistant shell 1, and at least two layers of outer pressure-resistant shells 2 are sheathed on the outer ring of the central pressure-resistant shell 1 in turn. Both the outer pressure-resistant shell 2 and the central pressure-resistant shell 1 are in the shape of a spherical shell.

[0032] The inner cavity of the central pressure-resistant shell 1 is used to store internal equipment and ensure the safety of people in the cabin. When the submersible is in operation, the central pressure-resistant shell 1 is kept airtight and the internal pressure is maintained at a standard atmospheric pressure.

[0033] Such as figure 1 and figure 2 In the shown embodiment, the outer pressure-resistant shell 2 located in the innermost layer can com...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com