Clamping arm device for clamping automobile tire

A technology of automobile tires and clamping arms, which is applied in the direction of chucks, manipulators, manufacturing tools, etc., can solve the problems of low vibration noise, high safety, and low safety, and achieve reduced vibration and noise, high safety, and clamping firm effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

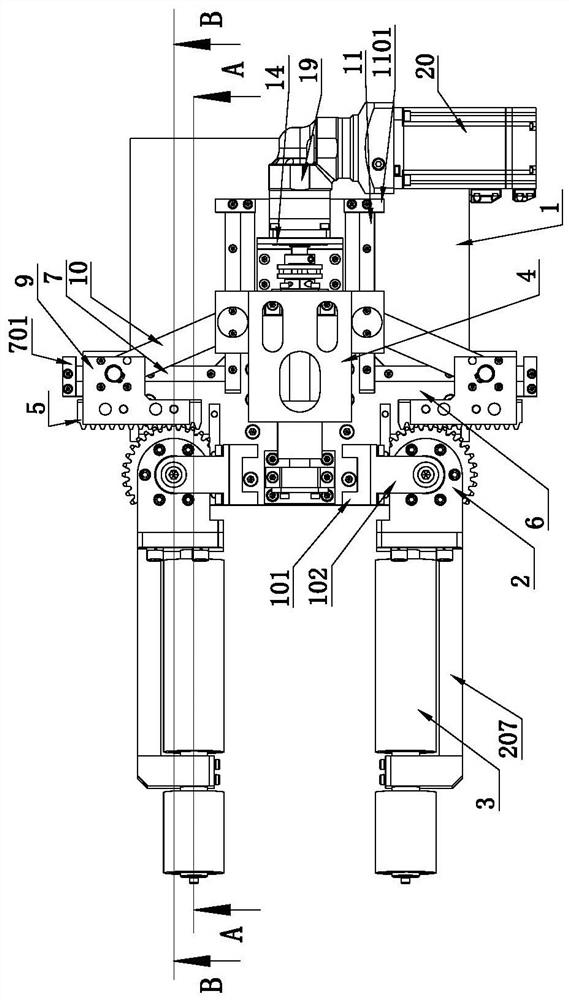

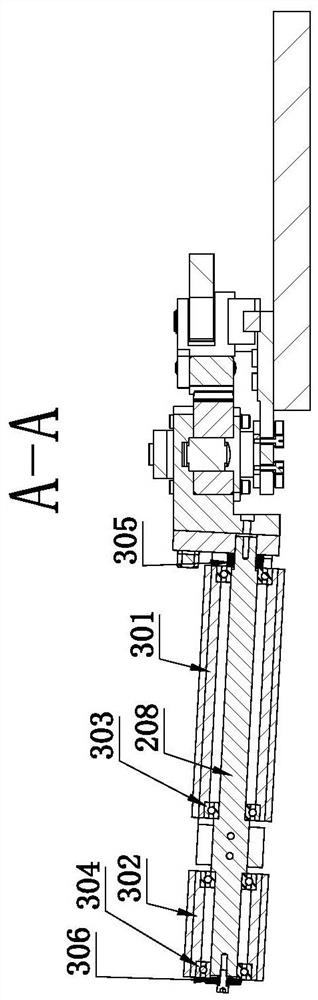

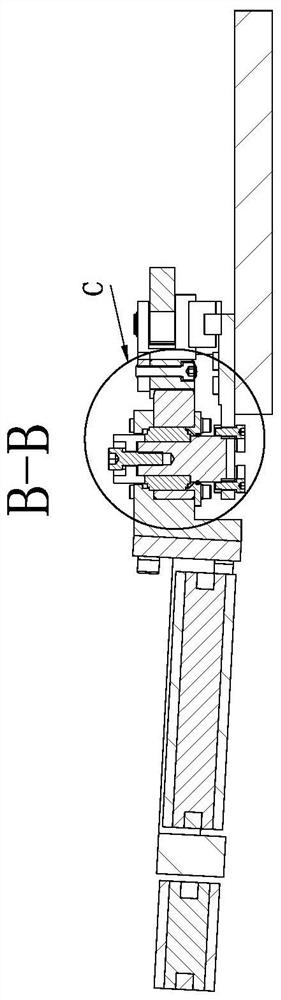

[0026] The present invention will be further described below in conjunction with the accompanying drawings.

[0027] Such as Figure 1-7 A clamping arm 3 device shown includes a base plate 1, and two sets of oppositely arranged rotating mechanisms 2 are connected to the base plate 1. The rotating mechanism 2 includes a gear seat 201 rotatably connected to the base, and one end of the gear seat 201 is connected to Transmission gear 202 is arranged, and the other end of gear seat 201 is rotatably connected with clamp arm 3 that extends outwards, and two clamp arms 3 can rotate in opposite directions, and gear seat 201 is provided with the bracket 207 that is arranged parallel to clamp arm 3, and gear The seat 201 is also provided with a fixed shaft 208, one end of the fixed shaft 208 is connected to the gear seat 201, and the other end of the fixed shaft 208 stretches out from the bracket 207 and extends outward. The clamp arm 3 includes an inner roller sleeve 301 and an outer r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com