Anti-deformation metal pipe cutting device

A cutting device and metal tube technology, applied in the attachments of shearing machines, pipe shearing devices, shearing devices, etc., can solve the problem of less cooling and cooling mechanism at the cutting place, poor stability of circular cross-section support, affecting the quality of the incision, etc. problems, to achieve the effect of improving cutting quality, increasing service life and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

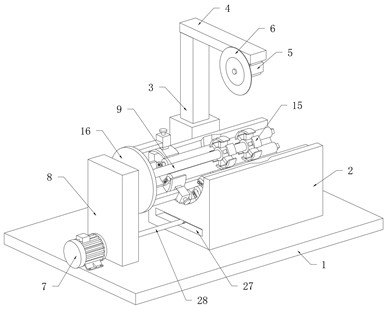

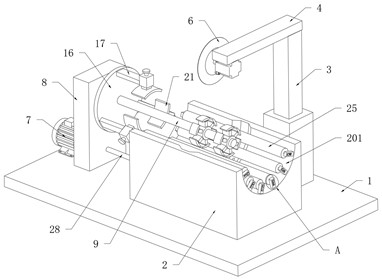

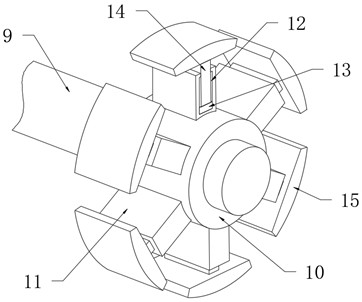

[0023] refer to Figure 1-2 , an anti-deformation metal pipe cutting device, comprising a base 1, a cutting table 2 is fixedly connected to the base 1, a second motor 7 is fixedly connected to the side of the base 1 away from the cutting table 2, and the cutting table 2 is close to the second motor 7 A gearbox 8 is fixedly connected at the position, the output shaft of the second motor 7 is connected with the gearbox 8, and a main shaft 9 is rotatably connected to the outer wall of the upper end of the gearbox 8. The main shaft 9 is provided with a clamping and fixing device. A cutting groove 201 with a semi-circular arc cross section is opened, and an auxiliary mechanism is provided on the cutting table 2 .

[0024] The cutting table 2 is fixedly connected with an electric lifting column 3, the upper end of the electric lifting column 3 is fixedly connected with a beam 4, and the bottom surface of one end of the beam 4 away from the electric lifting column 3 is fixedly connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com