Rapid catalyst coating device suitable for ceramic filter tube

A catalyst device and catalyst technology, which is applied to the device and coating of the surface coating liquid, can solve the problems of affecting production efficiency, affecting the use effect of ceramic filter tubes, and uneven catalyst coating, so as to achieve the goal of improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

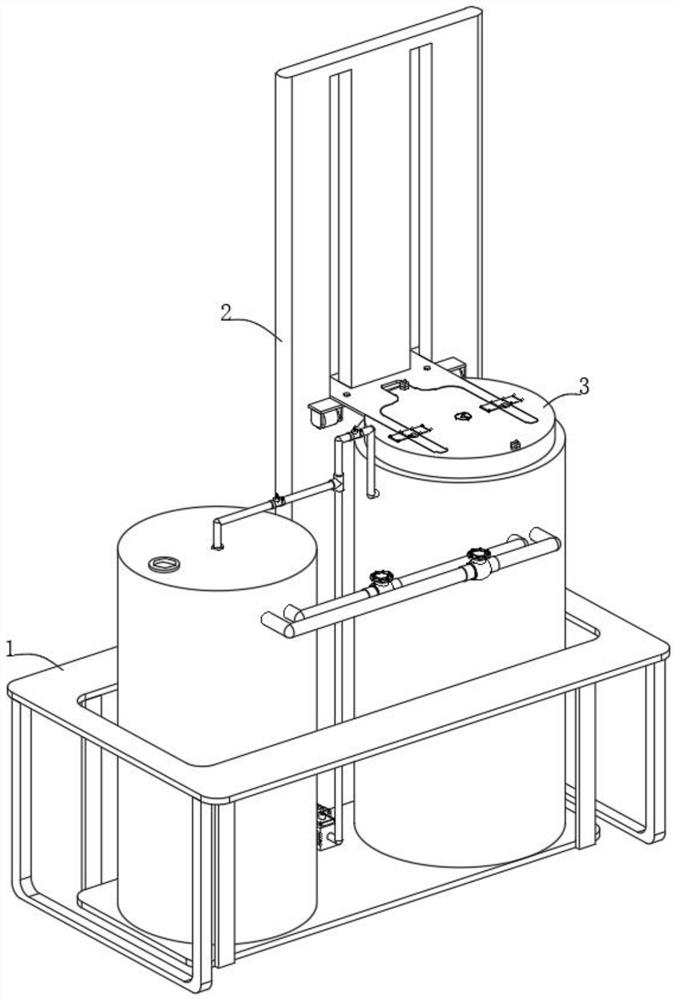

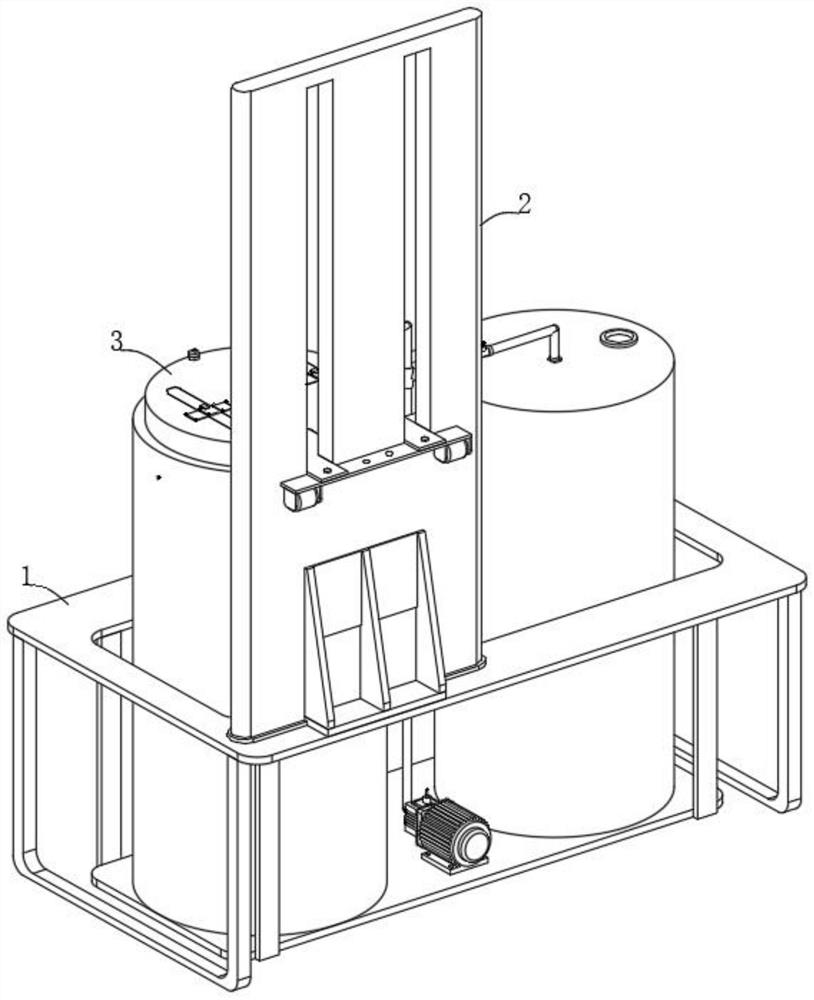

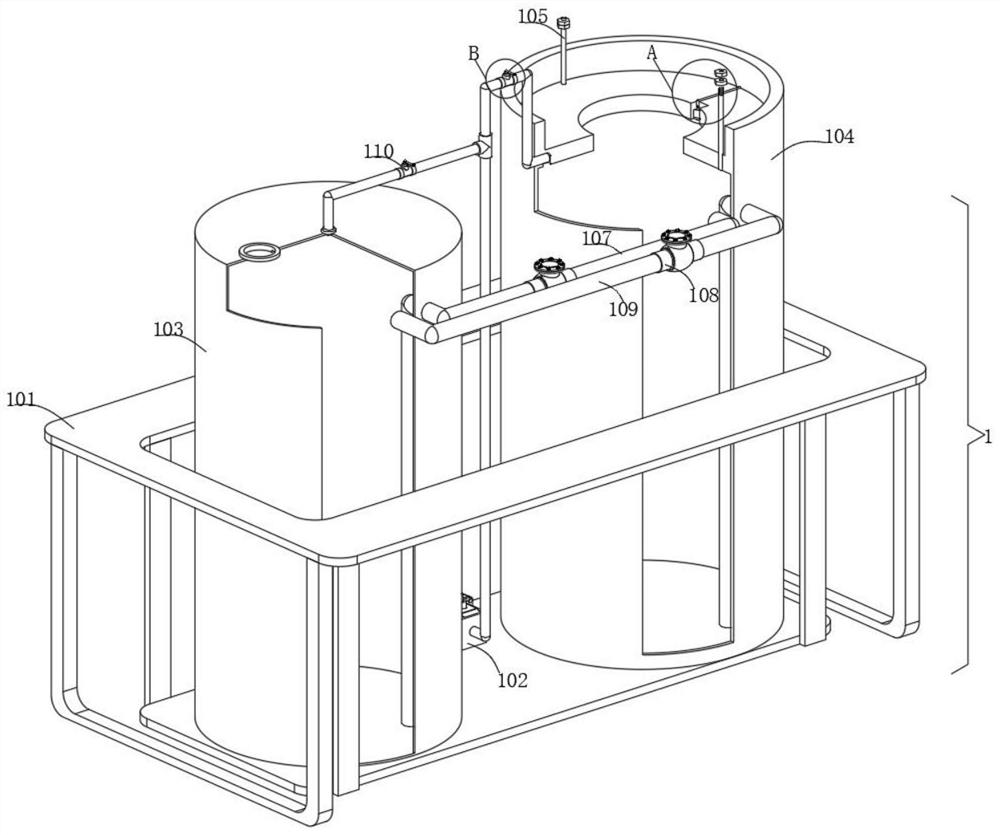

[0031] Embodiment one, with reference to Figure 1-9: A kind of rapid coating catalyst device applicable to ceramic filter tubes, comprising: a storage mechanism 1, the storage mechanism 1 includes a bottom frame 101 and conveying parts, the setting of the bottom frame 101 provides an installation basis for other functional parts of the equipment, the bottom The inner bottom surface of the frame 101 is fixedly connected with a catalyst stock solution barrel 103 near the center of one side edge. The catalyst stock solution barrel 103 is set up to facilitate the effective storage of the catalyst. The inner bottom surface of the bottom frame 101 is fixedly connected with a vacuum suction pump on one side of the catalyst stock solution barrel 103 102. The vacuum pump 102 is set up to provide the power required for catalyst transportation. The structure and principle of the vacuum pump 102 belong to the prior art, and will not be described in detail here. Its model can be selected a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com