Auxiliary device suitable for filtering of needle type filter

An auxiliary device and needle-type technology, which is applied in the fields of filtration and separation, measuring device, preparation of test samples, etc., can solve the problems of laborious filtration process, complicated steps, waste of extraction liquid, etc., so as to improve work efficiency and reduce frequent insertion. The effect of pulling and reducing workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

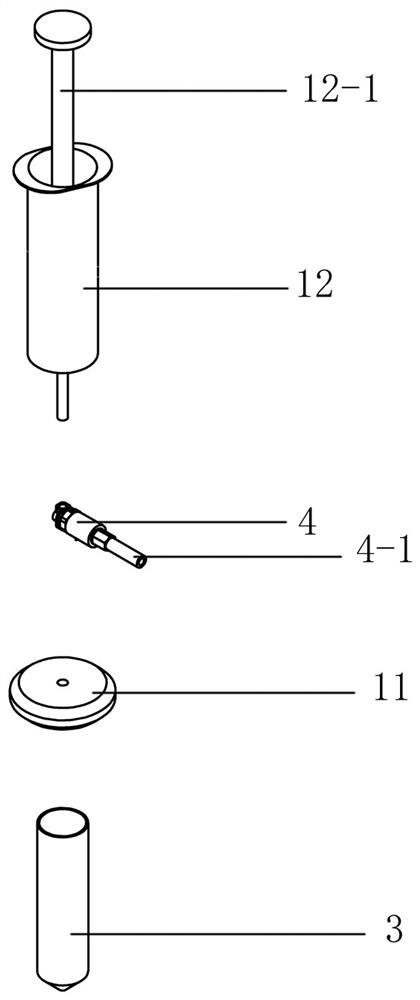

[0032] Such as figure 1 As shown, an auxiliary device suitable for needle filter filtration includes a needle piston 12, a two-position three-way valve 4, a filter 11 and a sampling bottle 3 distributed vertically in sequence, and the outlet of the needle piston 12 The liquid port is connected to the first interface of the two-position three-way valve 4, the outlet of the two-position three-way valve 4 is connected to the inlet of the filter 11, and the second interface 4-1 of the two-position three-way valve is a liquid suction port. During work, it is necessary to communicate with the external source of experimental liquid, and the outlet of the filter 11 is set corresponding to the inlet of the sampling bottle 3 .

[0033] When in use, it can be operated manually. The pressure change during the suction and discharge process of the needle piston 12 forces the two-position three-way valve 4 to switch between the two channels. During the suction process, the two-position three...

Embodiment 2

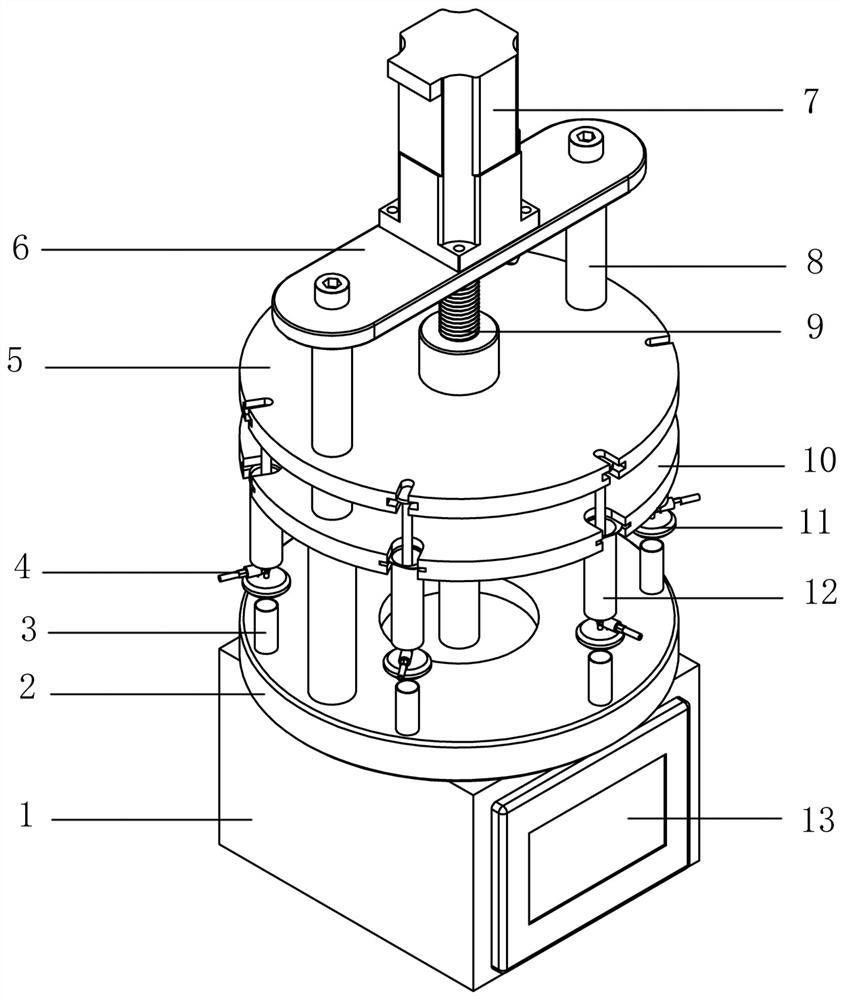

[0037] In order to realize batch operations, a base plate 2, a bracket 8, a lifting plate 5 and a pin piston mounting plate 10 are also designed, and the pin type piston mounting plate 10 is fixed on the middle part of the bracket 8, and the base plate 2 is fixed on the bottom of the bracket 8. Bottom, the lifting plate 5 is located above the needle piston mounting plate 10, the bottom plate 2 is provided with a station for placing the sampling bottle 3, and the needle piston 12 is installed on the needle piston mounting plate 10 And facing the station, the piston rod 12-1 of the needle piston 12 is fixed on the lifting plate 5, the lifting plate 5 is driven up and down by the driving mechanism, and the two-position three-way valve 4 is connected And be fixed on the output end of needle piston 12.

[0038]The drive mechanism includes a drive motor 7, a lead screw 9 and a top plate 6, the support 8 is a vertical guide post, and the drive motor 7 is fixed on the top plate 6. In ...

Embodiment 3

[0046] Such as figure 2 As shown, the main difference between this embodiment and embodiment 2 is:

[0047] The lifting plate 5, the bottom plate 2 and the needle piston mounting plate 10 are all in-line strips, and the needle piston 12, sampling bottle 3, filter 11 and two-position three-way valve 4 are all distributed along a straight line.

[0048] The form of linear arrangement is suitable for the working environment where the operating table is long. When operating each sampling bottle, the degree of mutual interference is small and the operating space is large.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com