On-line weighing fluid densimeter of isolation system

A fluid density and fluid technology, which is applied in the field of automatic on-line sampling liquid density measuring devices, can solve the problems of affecting the measuring accuracy, clogging of the on-line density meter, and heavy weighing weight, etc., and achieves simple device structure, high measuring accuracy, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Below in conjunction with accompanying drawing, the present invention is described in further detail:

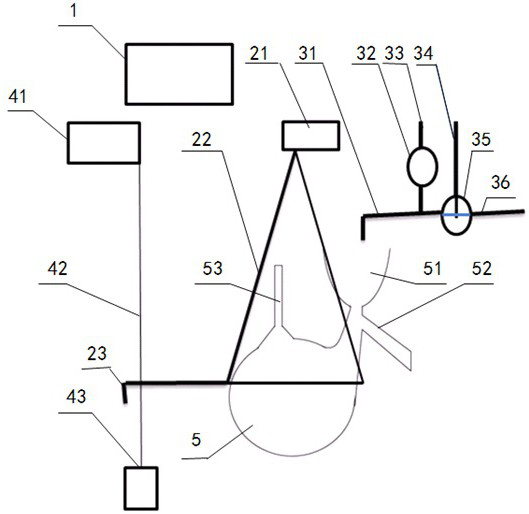

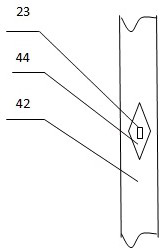

[0018] Such as figure 1 As shown, a fully automatic on-line weighing fluid density meter capable of isolating the system and dumping samples of the present invention includes independently installed weighing devices 2, volumetric bottles 5, clear water and measured fluid sampling devices 3, and lifting devices 4 and the controller 1, a weighing module 21 for weighing is arranged above the bottom of the volumetric flask 5, a volumetric flask exhaust port 53 is arranged on the top of the volumetric flask 5, and a volumetric flask funnel 51 is arranged above the volumetric flask 5, the The bottom nozzle wall of the volumetric flask funnel 51 is provided with a volumetric flask overflow port 52, the lifting device 4 contains a lifter 41, a lifting line 42, a lifting line hole 44 and a weight 43, and the weighing device 2 includes a weighing Support 22, weighing module 21...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com