Automatic smearing and rotating equipment for round cakes

A technology for rotating equipment and cakes, which is applied to cleaning methods and utensils, chemical instruments and methods, and cleaning methods using tools, etc., can solve the problems of inability to limit the position of cakes and automatic cleaning of smear blades, and achieve the effect of simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

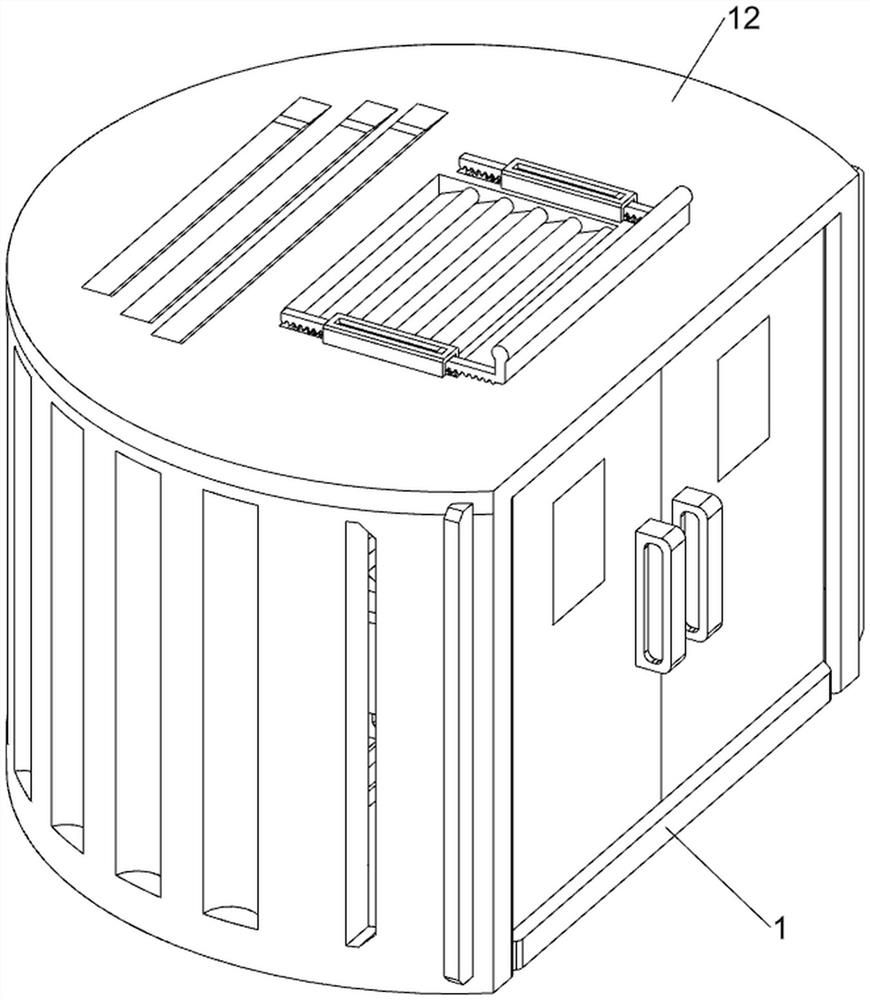

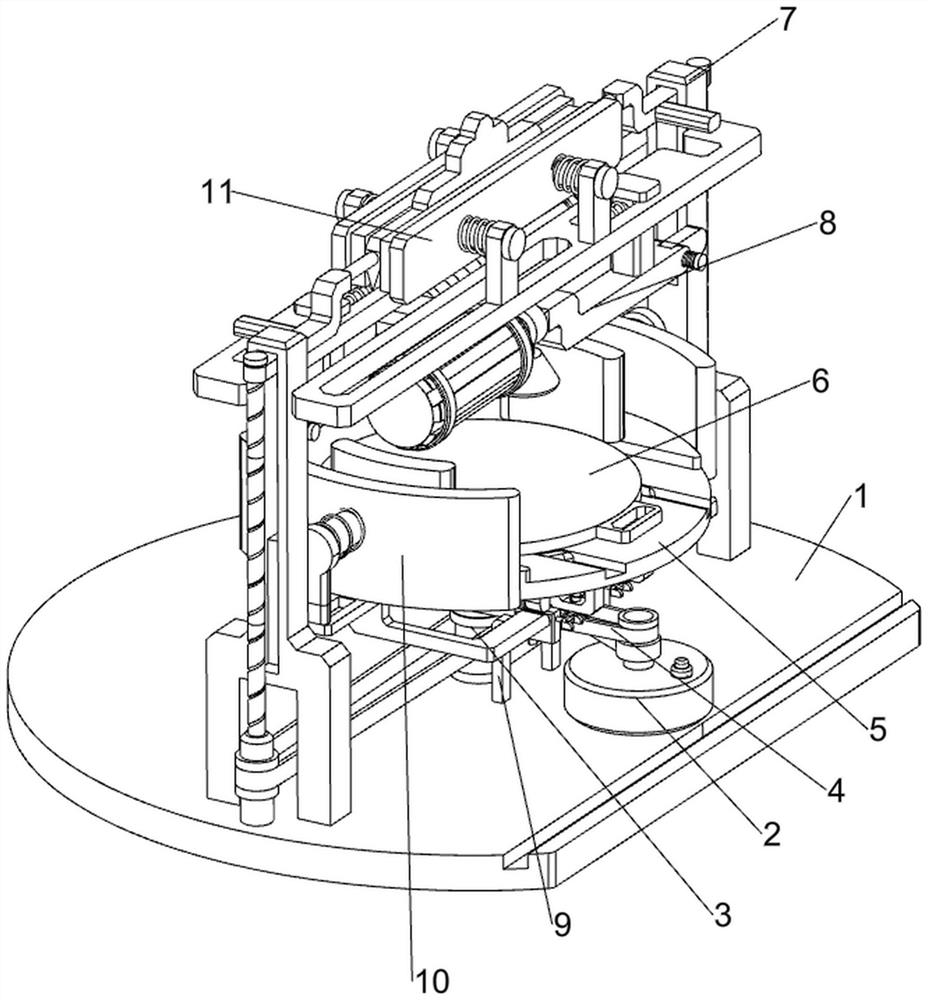

[0028] A round cake automatic spreading rotating equipment, such as Figure 1-5 As shown, it includes a base plate 1, a motor 2, a first rotating shaft 3, a first belt 4, a turntable 5, a movable plate 6, a scraping mechanism 7 and a material spraying mechanism 8, and a motor 2 is arranged in the middle of the right side of the base plate 1, and the base plate 1 The middle rotating shaft 3 is connected with the first rotating shaft, the first belt 4 is wound between the middle of the first rotating shaft 3 and the output shaft of the motor 2, the top of the first rotating shaft 3 is provided with a turntable 5, and the top of the turntable 5 is slidingly connected with a movable disc 6, The bottom plate 1 is provided with a scraping mechanism 7, and the scraping mechanism 7 is provided with a spraying mechanism 8.

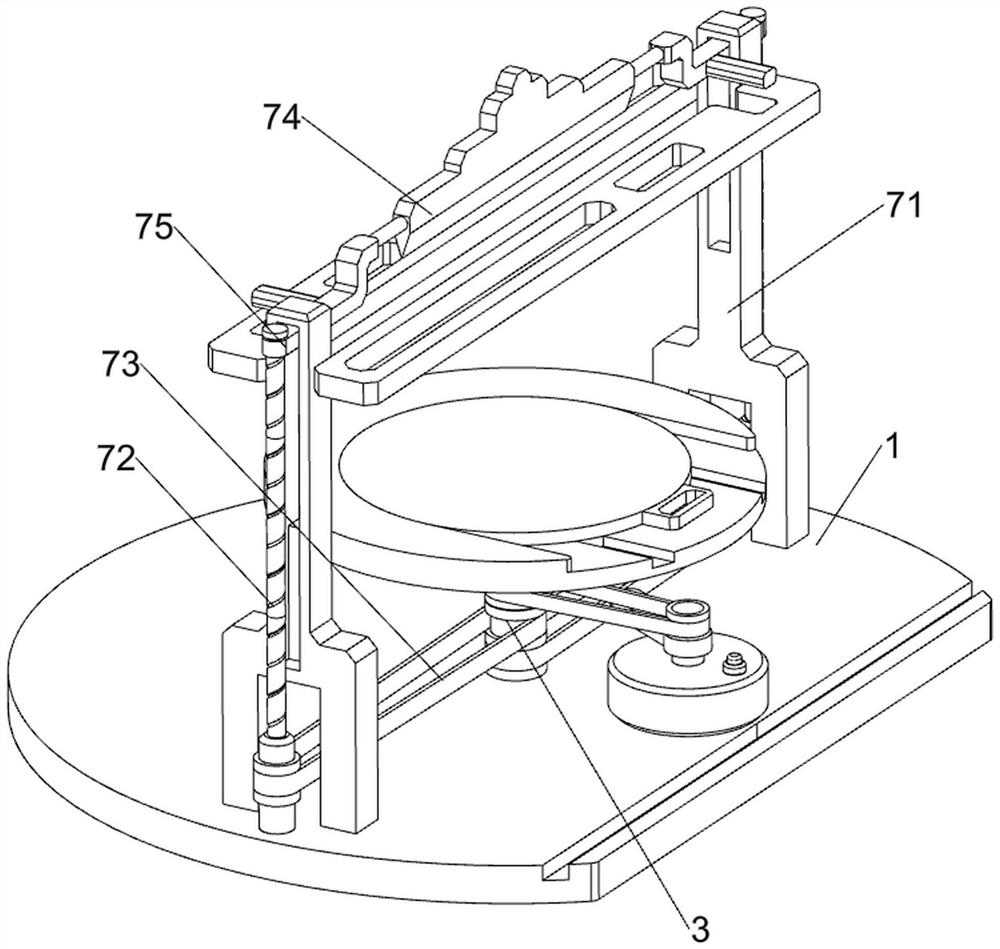

[0029] The scraping mechanism 7 includes a support frame 71, a screw mandrel 72, a second belt 73, a first movable plate 74, a first movable block 75, a second mov...

Embodiment 2

[0033] On the basis of Example 1, such as Figure 6-10 Shown, also include clamping mechanism 9, clamping mechanism 9 first support column 91, first movable frame 92, the 3rd compression spring 93, the second support column 94, the second movable frame 95 and the 4th compression spring 96 , the front and rear sides of the bottom right side of the turntable 5 are connected with the first support column 91, the first movable frame 92 is slidably connected between the first support columns 91, the first movable frame 92 is slidably connected with the turntable 5, the first movable A third compression spring 93 is provided between the front and rear sides of the upper part of the frame 92 and the first support column 91, and a second support column 94 is connected to the front and rear sides of the right part of the base plate 1, and a sliding connection is made between the second support columns 94. The second movable frame 95, the motor 2 output shaft bottom is provided with a d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com