Automatic remote centralized control system and centralized control method for main shaft loading

A technology of centralized control system and monitoring system, applied in general control system, control/regulation system, program control and other directions, can solve problems such as low work efficiency, complex operating procedures, hidden safety hazards, etc., to improve work efficiency and optimize personnel allocation , the effect of maximizing benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention is described in detail below with reference to accompanying drawing and embodiment:

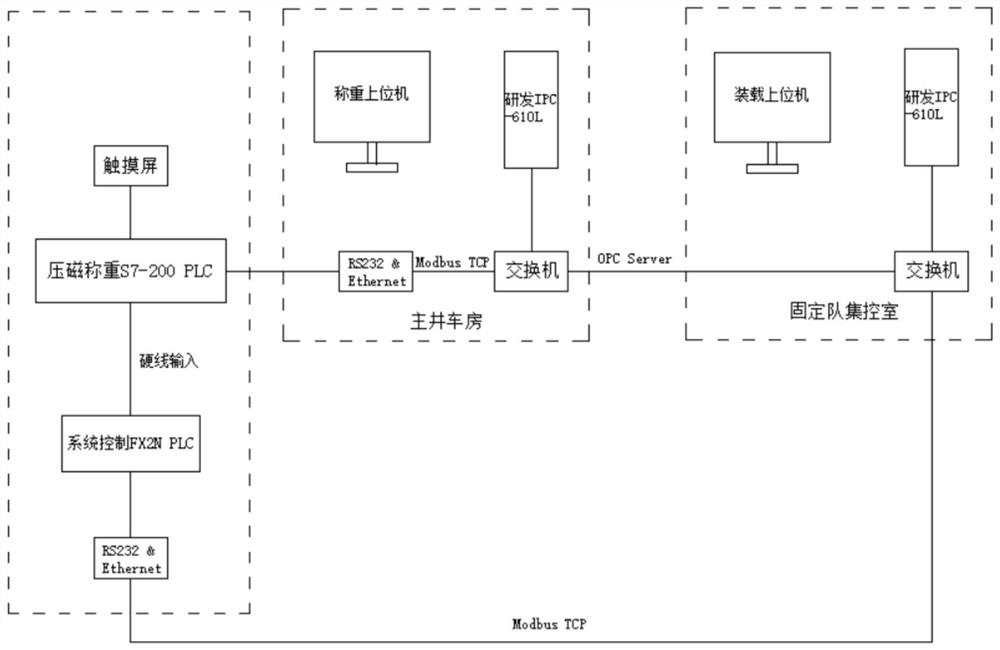

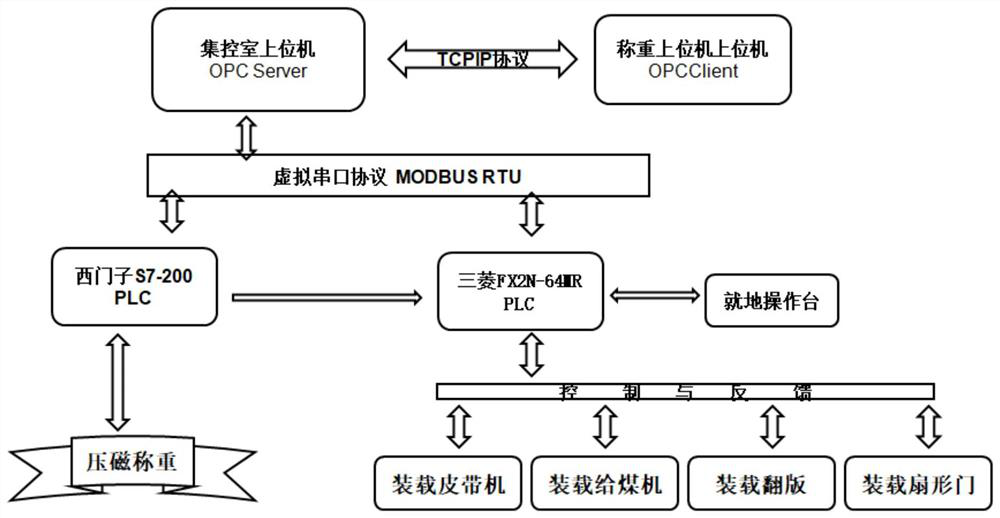

[0059]attached figure 1 and 2 It can be seen that an automatic remote centralized control system for main well loading,

[0060] Including: main well loading chamber, main well vehicle room pressure monitoring system and centralized control room;

[0061] The loading chamber of the main well, the pressure monitoring system of the main well garage and the centralized control room exchange data through optical fiber networking to realize the collection and control of equipment status information;

[0062] The hardware of the central control room is composed of network switches, optical fiber transceivers, and industrial computers;

[0063] The loading chamber control system includes Mitsubishi FX2N-64MR programmable controller, Siemens S7-200 programmable controller and mine explosion-proof vacuum magnetic starter;

[0064] The house pressure monitoring system o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com