Special cutting device for Overlay test piece

A technology for cutting devices and test pieces, which is applied in the preparation and sampling of measuring devices, samples for testing, etc., can solve the problems of material waste, consumption, large time and labor costs, and achieves reduction of redundant operations, flexible control, and improved efficiency. The effect of precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific method of the present invention will be described in detail below in conjunction with the accompanying drawings.

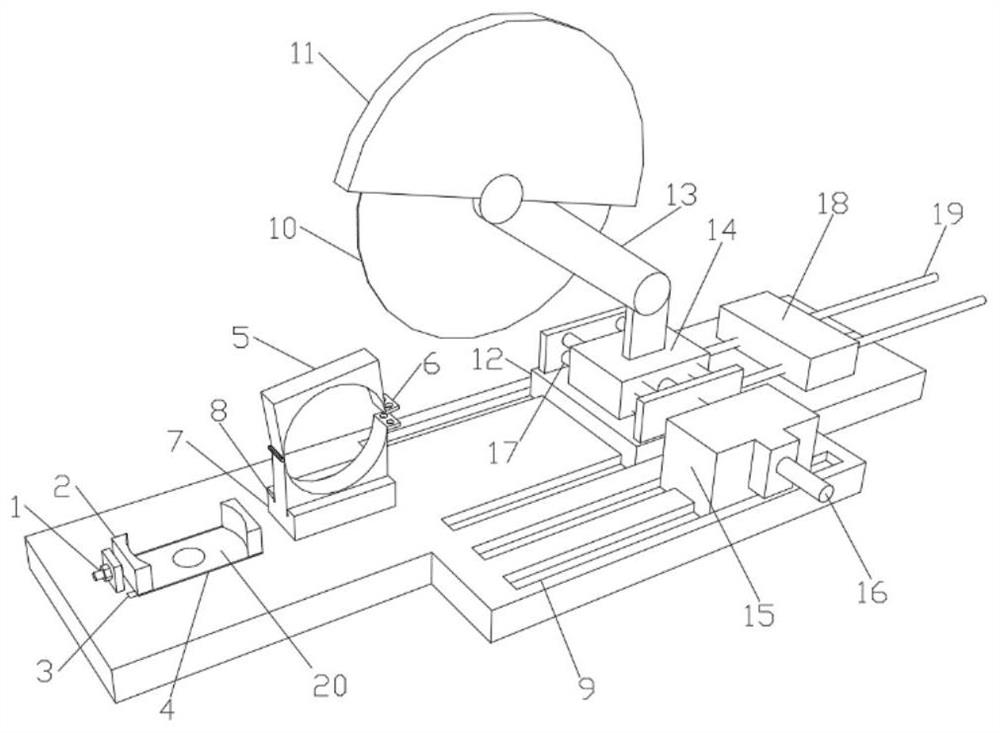

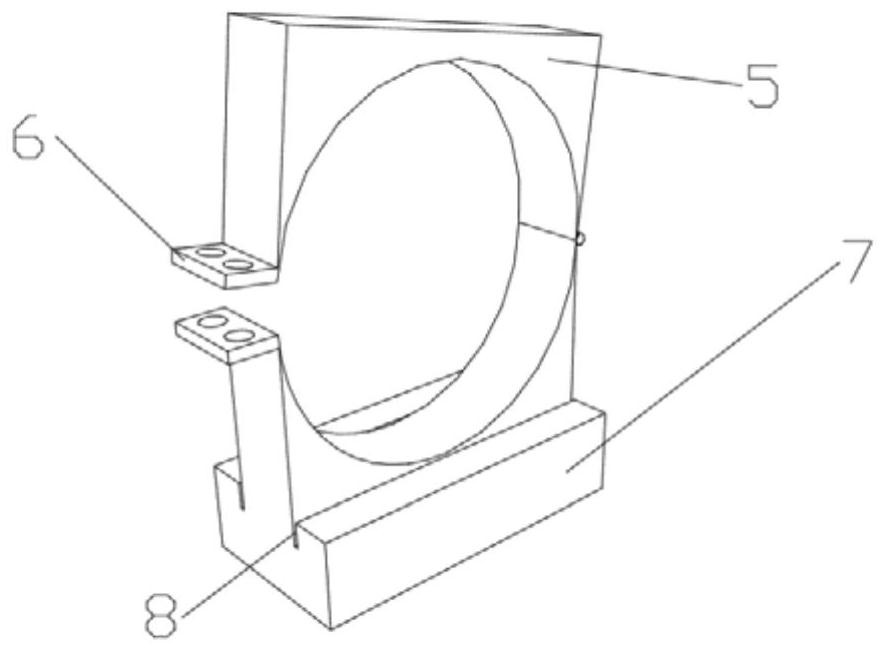

[0026] Such as figure 1 As shown, a special cutting device for Overlay specimens, including telescopic bolt 1, sliding side plate 2, side plate slide rail 3, vertical cutting reserved cutting seam 4, rotatable upper clamp 5, flange buckle 6, cross-cutting clamp 7. Cutting seam reserved for cross cutting 8, blade base slide rail 9, cutting blade 10, blade guard 11, blade base 12, blade bracket 13, lateral movable support 14, lateral control motor 15, lateral pressure bar 16, lateral Slide bar 17, longitudinal control motor 18, longitudinal pressure bar 19, vertical cutting fixture 20.

[0027] Such as figure 2 As shown, the vertical cutting fixture 20 fixes the specimen through two side plates. The plate 2 is placed on the test piece, the displacement range of the sliding side plate 2 on the side plate slide rail 3 is 0 ~ 10mm, there are ver...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com