Fixing device for oil seal of rear axle swing frame of mining load wagon

A technology for fixing devices and rocking frames, which is applied to axles, wheels, vehicle parts, etc., can solve the problems of increasing the replacement cycle of oil seals and bushings, reducing the service life of oil seals, increasing the labor cost of replacing bushings, etc., to save labor costs , increase the service life, the effect of efficient and convenient replacement scheme

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

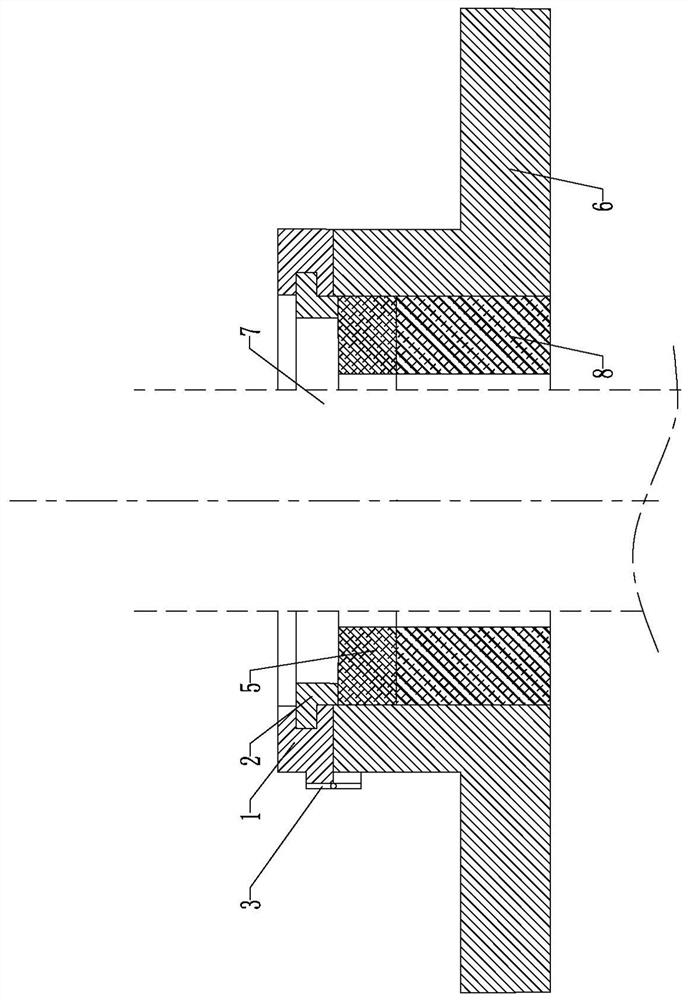

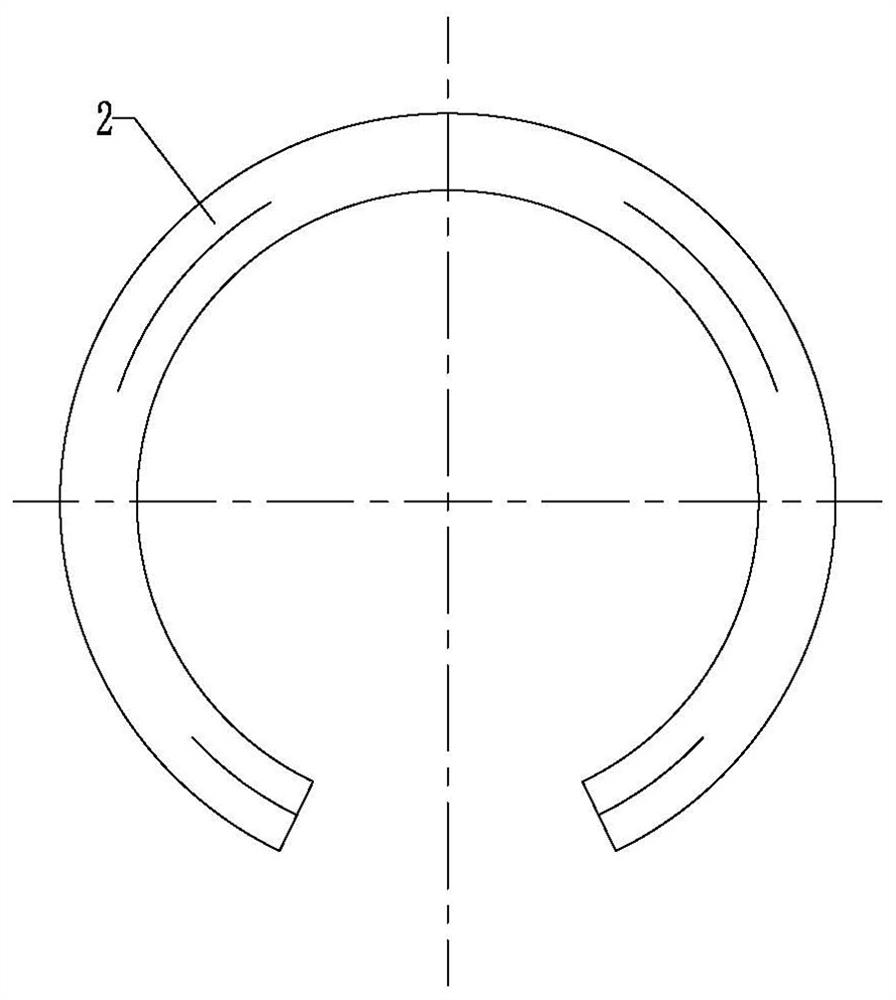

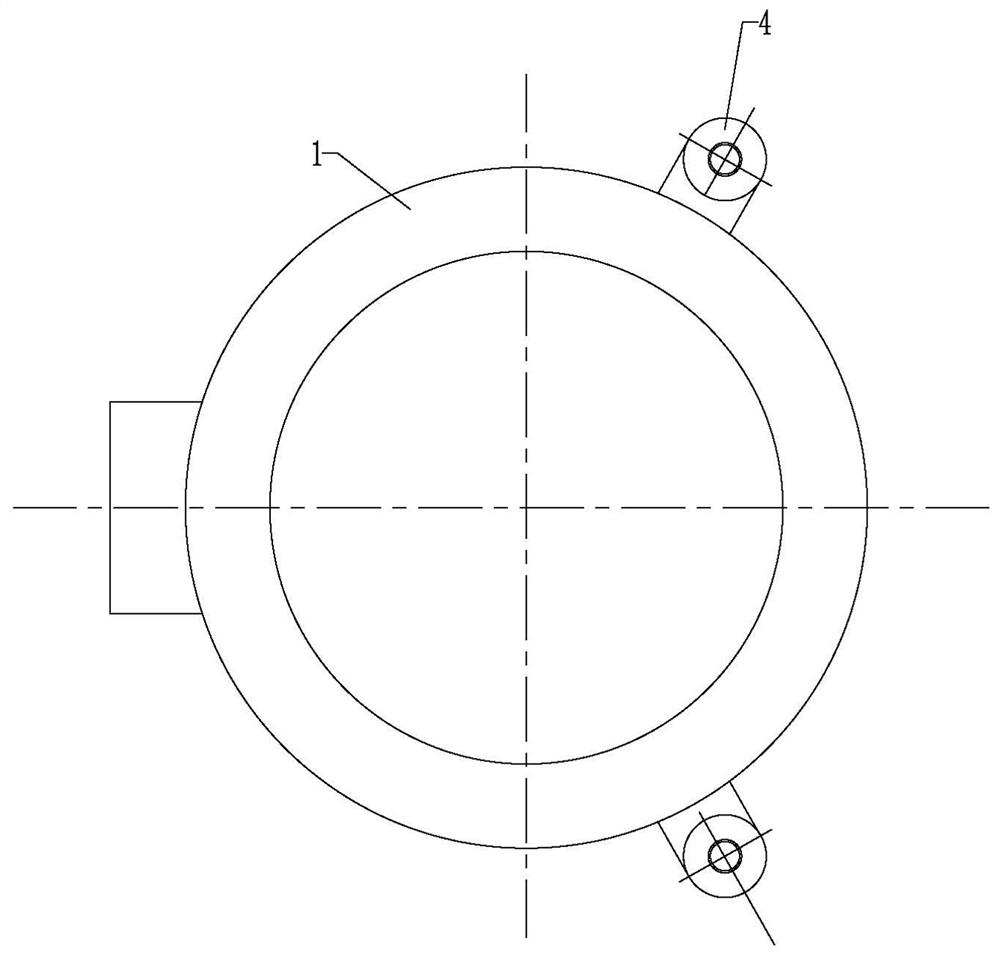

[0019] Example 1, such as figure 1 As shown, a mine loading vehicle rear axle rocking frame oil seal fixing device includes an oil seal cover 1 and a ring piece 2; the oil seal cover 1 is fixed on the upper end surface of the upper part 6 of the swing frame, and is used to fix the oil seal cover 1 of the ring piece 2, and the oil seal The inner side of the cover 1 has an annular groove, and the section of the ring piece 2 is inverted L-shaped. The oil seal cover 1 is connected with the upper part 6 of the swing frame through the hinge 3, and the oil seal cover 1 is fixed with the upper part 6 of the swing frame through the pin hole 4. The oil seal fixing device of the swing frame is on When working, the oil seal cover 1 is connected and fixed with the upper part 6 of the rocking frame. The inner side of the oil seal cover 1 is provided with an annular groove, and the cross section of the ring piece is in an inverted L shape. Interference section; the clip-in section is placed ...

Embodiment 2

[0022] Embodiment 2, the oil seal fixing device also includes a connecting device; the connecting device includes a pin shaft 10, an upper pin hole 4 and a lower pin hole 9, and the outer end surface of the oil seal cover 1 is provided with several upper pin holes, and on the outer end surface of the upper part 6 of the swing frame Several lower pin holes 9 are preset at the corresponding positions; the oil seal cover 1 is fixed on the upper part 6 of the swing frame through the corresponding upper pin holes 4 and lower pin holes 9 through the pin shaft 10 . A hinge 3 is arranged on the outer end surface of the oil seal cover 1, and the oil seal cover is mounted on one side of the upper part 6 of the rocking frame through the hinge 3 which can be opened. The outer end surface of the oil seal cover 1 is provided with two upper pin holes 4, and two lower pin holes 9 are preset at the corresponding positions on the outer end surface of the swing frame, and the upper pin holes 4 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com