Gantry crane with adjustable span height

A gantry crane and height technology, which is applied in the direction of load block, load suspension components, trolley cranes, etc., can solve the problems of inconvenient movement of gantry cranes, reduce the service life of the lifting mechanism, and low lifting strength, so as to ensure stability and span Applicability, free adjustment of height and span, and the effect of improving lifting capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

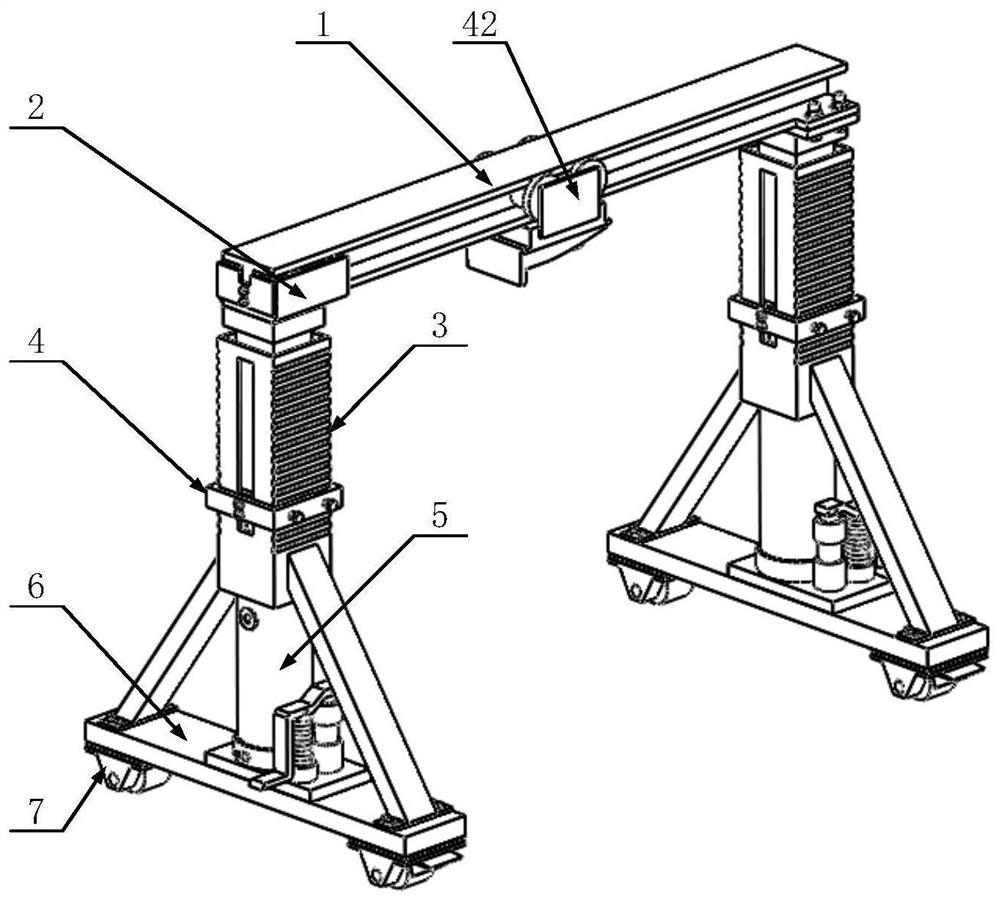

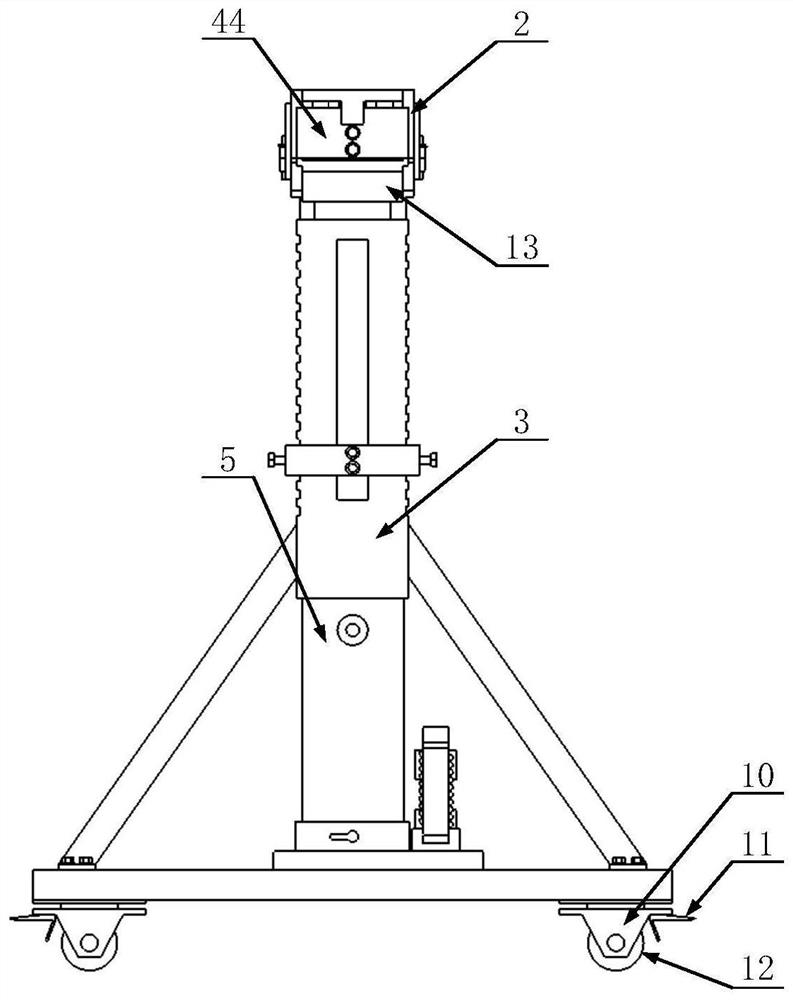

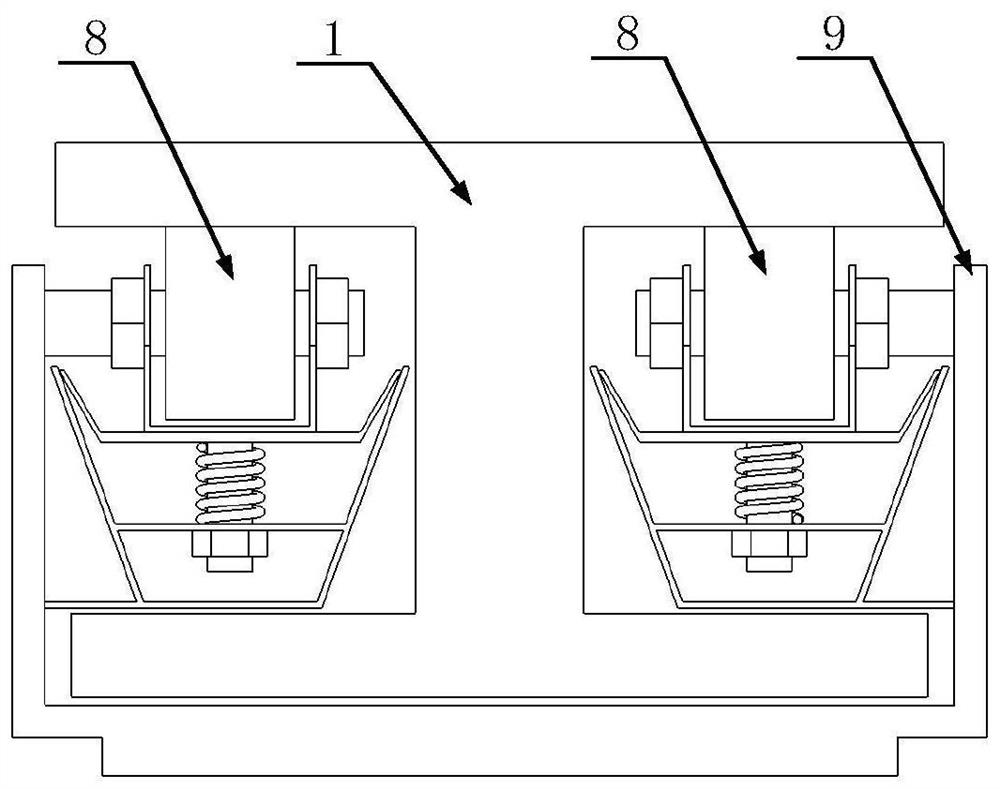

[0028] Embodiment 1: as Figure 1-9 As shown, a gantry crane with adjustable span height includes an I-shaped beam 1, a lifting device 42 is slidably installed on the I-shaped beam 1, and the lifting device 42 can move freely in the horizontal direction on the I-shaped beam 1, and also includes Traversing mechanism 2, hydraulic lifting device 5; wherein one end of the I-shaped beam 1 is fixedly connected with a hydraulic lifting device 5 through bolts, the other end of the I-shaped beam 1 is slidingly connected with the traversing mechanism 2, and the traversing mechanism 2 is connected to another A hydraulic lifting device 5 is fixedly connected by welding, the traverse mechanism 2 is used for lateral movement, and the hydraulic lifting device 5 is used for adjusting the height of the I-shaped beam 1 . That is to say, the lateral movement mechanism is set on one side. Through this setting, the span can be better adjusted to avoid the lack of adjustment caused by both sides mo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com