Conveyor with self-unloading and stacking functions

A conveyor and palletizer technology is applied in the field of conveyor palletizing equipment to achieve the effects of improving conveying speed, fast unloading speed, and speeding up palletizing speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The specific content of the present invention is further described below:

[0040] The invention is a conveyor with self-unloading and palletizing functions, which realizes the integrated setting of the palletizing structure of the conveyor, and can realize simultaneous operation of conveying and palletizing.

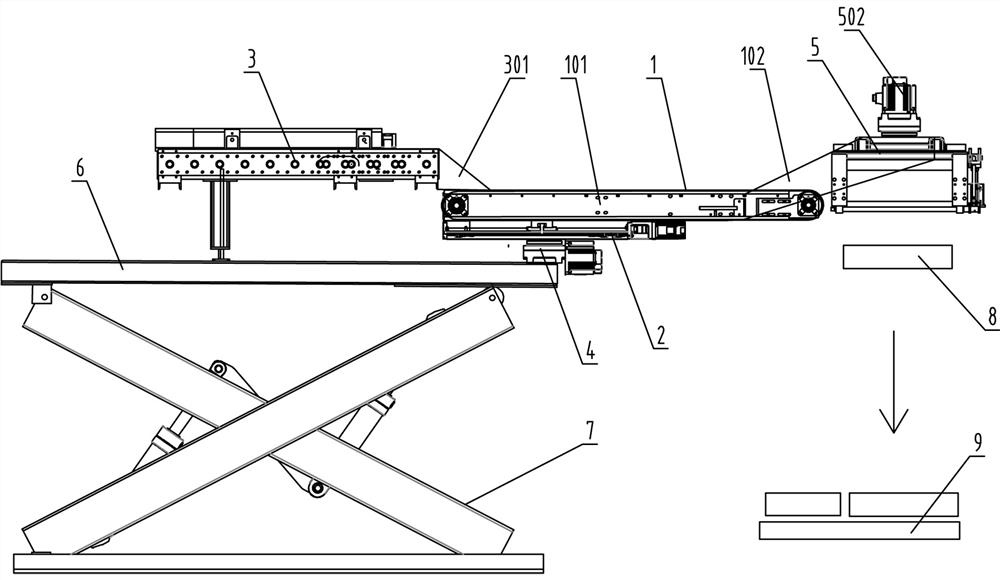

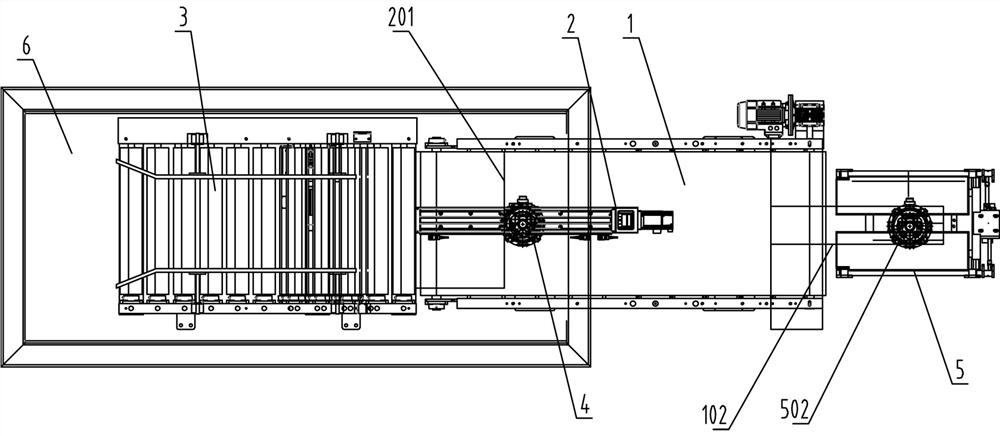

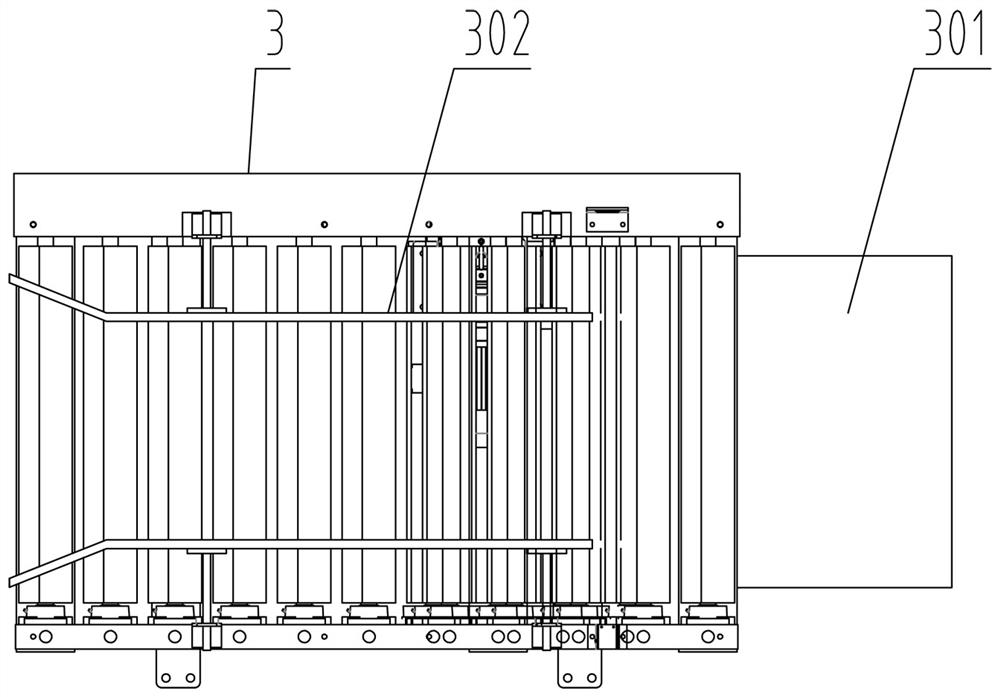

[0041] The structure of the present invention is as figure 1 and figure 2 As shown, it includes a forward extension mechanism 2 , a forward extension conveyor 1 , an incoming material conveyor 3 , a servo rotary drive machine 4 and a stacking mechanism 5 .

[0042] like image 3 , 4 and Figure 5 As shown, the protruding mechanism 2 includes a protruding slider 201, a linear guide rail 202 and a linear drive mechanism. The protruding slider 201 is arranged on the linear guide rail 202 and is driven by the linear drive mechanism to move the protruding slider 201 along the linear track.

[0043] The forward extension mechanism 2 is used to drive the forward e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com