A heat shrink curing device

A curing device and heat shrinking technology, applied in the directions of instruments, optics, light guides, etc., can solve the problems of low heat shrinkage curing efficiency and heat loss of heat conduction blocks, so as to improve the heat shrinkage curing efficiency, uniform heating, and improve the heat shrinkage curing efficiency. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

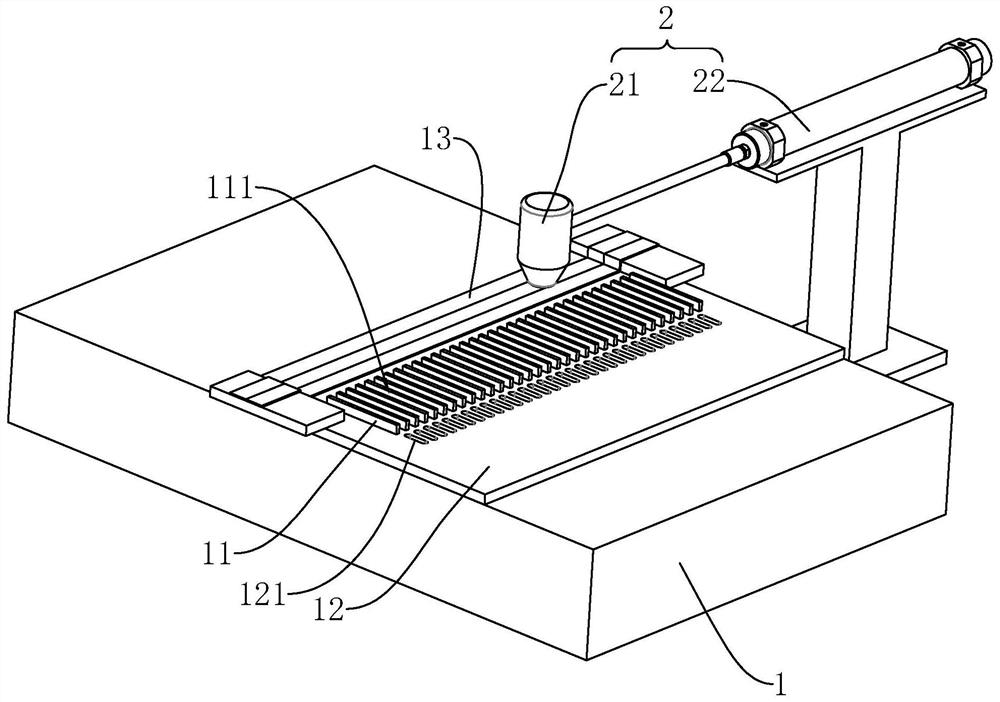

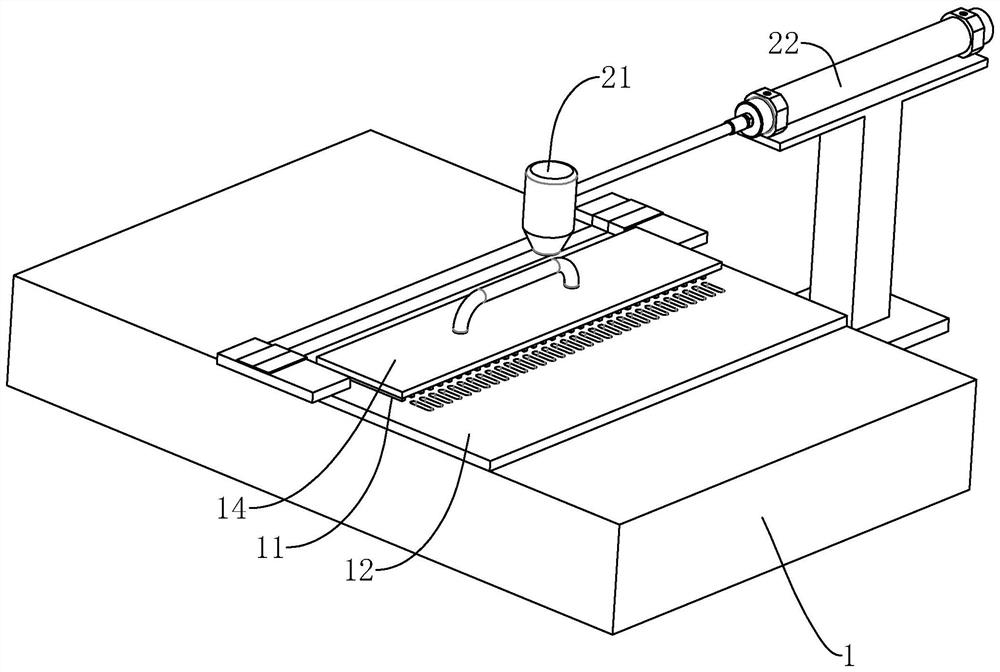

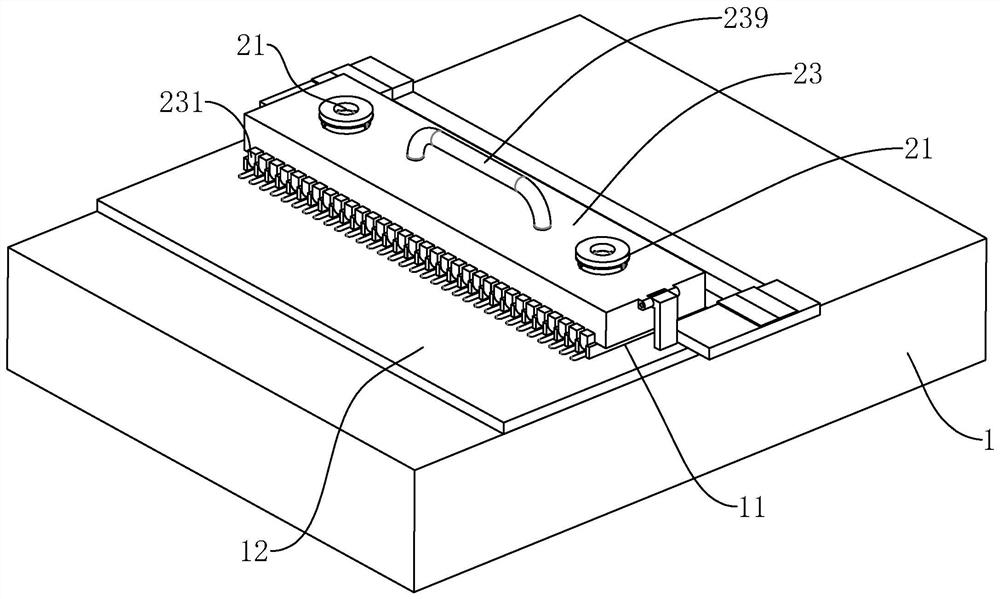

[0048] Embodiment 2, differs from embodiment 1 in that, as image 3 , Figure 4 As shown, the mobile hot air assembly 2 includes a bar-shaped housing 23, a hot air blower 21 and a driving mechanism, wherein the hot air blower 21 is fixed on the upper surface of the bar-shaped housing 23, and the air outlet end of the hot air blower 21 is connected to the bar-shaped housing 23. Communication, that is, the hot air blower 21 is used to inject positive pressure hot air into the inner cavity of the bar-shaped housing 23 .

[0049] like image 3 As shown, the length direction of the bar-shaped housing 23 is arranged along the length direction of the heat-conducting block 11, one end of the bar-shaped housing 23 is hingedly connected with the heating furnace body 1, and the upper surface of the bar-shaped housing 23 is provided with a heat-resistant silicone rubber material. The handle 239 is formed, and the handle 239 is used to drive the bar-shaped housing 23 to turn over; the si...

Embodiment 3

[0058] Embodiment 3, on the basis of embodiment 2, make the following settings, as Figure 10 As shown, the two opposite wide sides of the wind deflector 233 are provided with a plurality of follower plates 25, the follower plates 25 are thin metal plates, the follower plates 25 and the wind deflector 233 are arranged at the same length, and one length of the follower plate 25 is equal. The side edges and the wind deflector 233 are hingedly connected through hinges.

[0059] When the wind deflector 233 rotates, the follower plate 25 is partially in a vertical state and partially adheres to the surface of the wind deflector 233 due to gravity, and the follower plate 25 in the vertical state can guide the hot air to a certain extent. function, so that the hot air in the bar-shaped housing 23 can be concentrated as much as possible, so as to improve the effect of centralized heating.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com