Gas turbine multi-sensor fault detection method based on hybrid method

A gas turbine and multi-sensor technology, which is applied in internal combustion engine testing, complex mathematical operations, design optimization/simulation, etc., can solve problems such as insensitivity of multi-sensor fault detection, and achieve the effect of strong promotion significance and improved detection accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

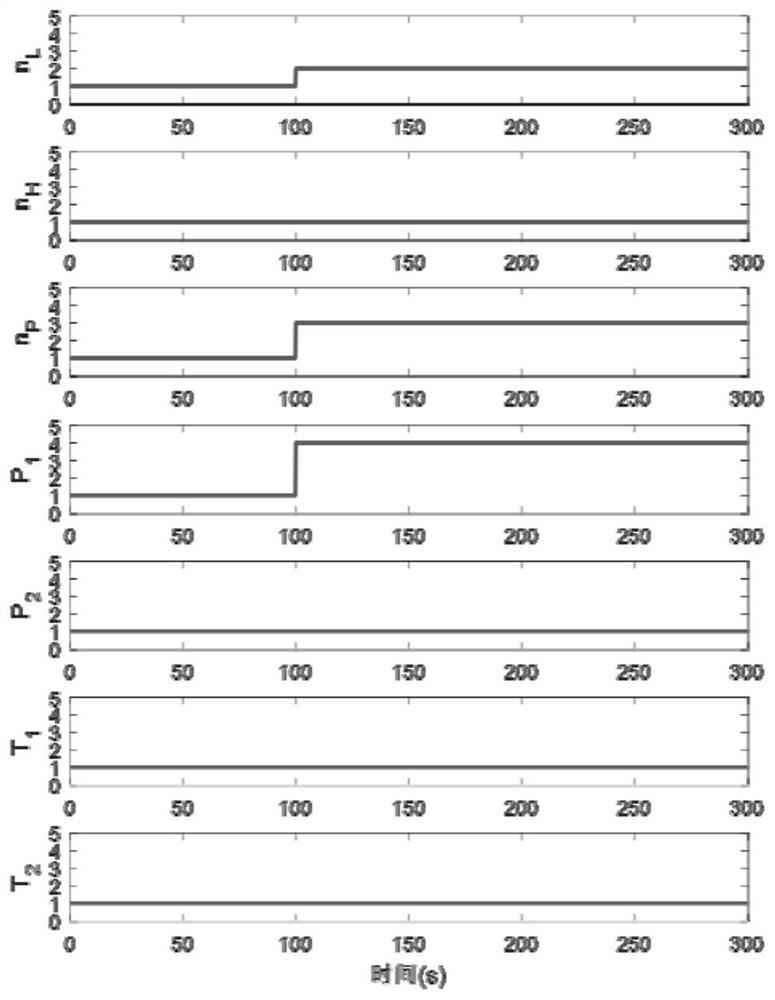

[0075] In order to verify the effectiveness of the proposed method of the present invention, the following experiments are designed on the three-shaft gas turbine simulator set up now:

[0076] Gas turbine fuel flow q mfe Increase from 90% to 100% at a constant speed within 300s to indicate that the gas turbine is in a state of variable operating conditions. In the experiment, 7 sensors were selected as the sensors to be detected, respectively n H , n L , n P Low pressure compressor outlet temperature (T 1 ) and pressure (p 1 ) and high pressure compressor outlet temperature (T 2 ) and pressure (p 2 ). Fault is set at 100s when n L , n P and p 1 The bias failure of the three sensors occurred at the same time, and the severity of the failure was 1% of the parameters under the standard operation of the gas turbine, and the simulation time interval was 0.01s.

[0077] Based on the method proposed in the present invention, firstly, the parameter identification of the eq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com