camera

A camera and camera technology, applied in the field of cameras, can solve problems such as complex structure, large camera internal space, and reduce the cost of the whole machine, so as to achieve the effect of horizontal rotation and vertical rotation, improve control accuracy, and reduce the cost of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

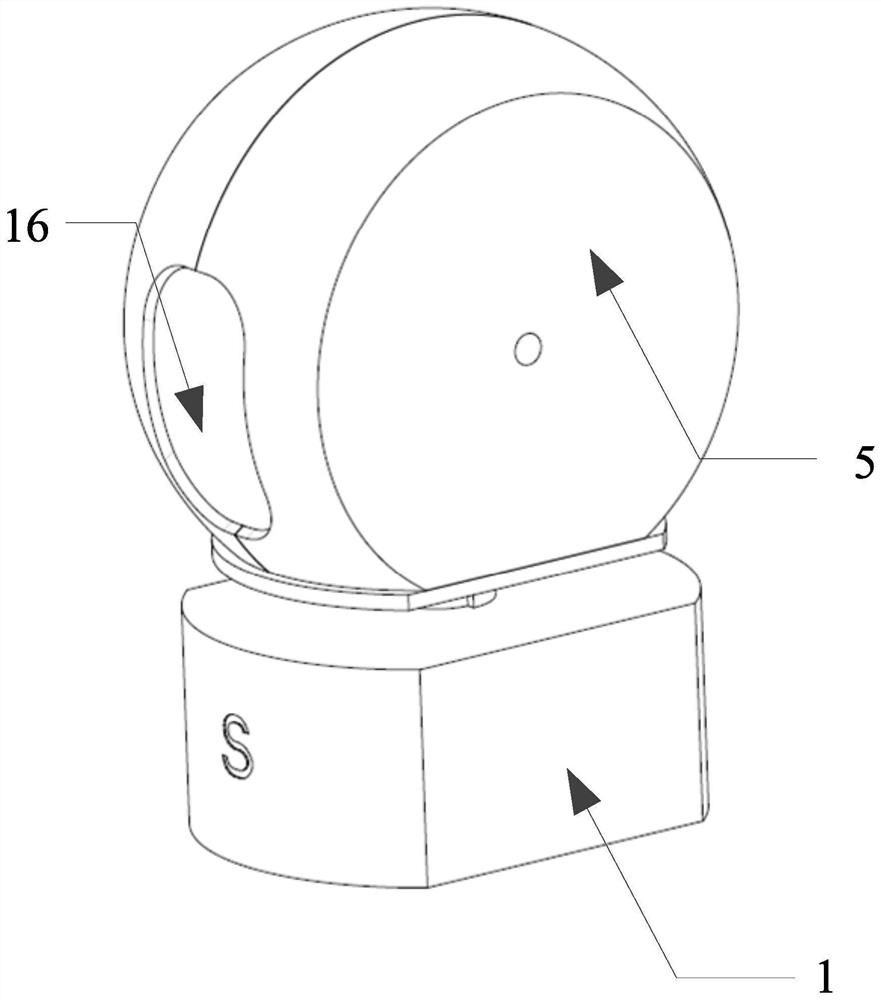

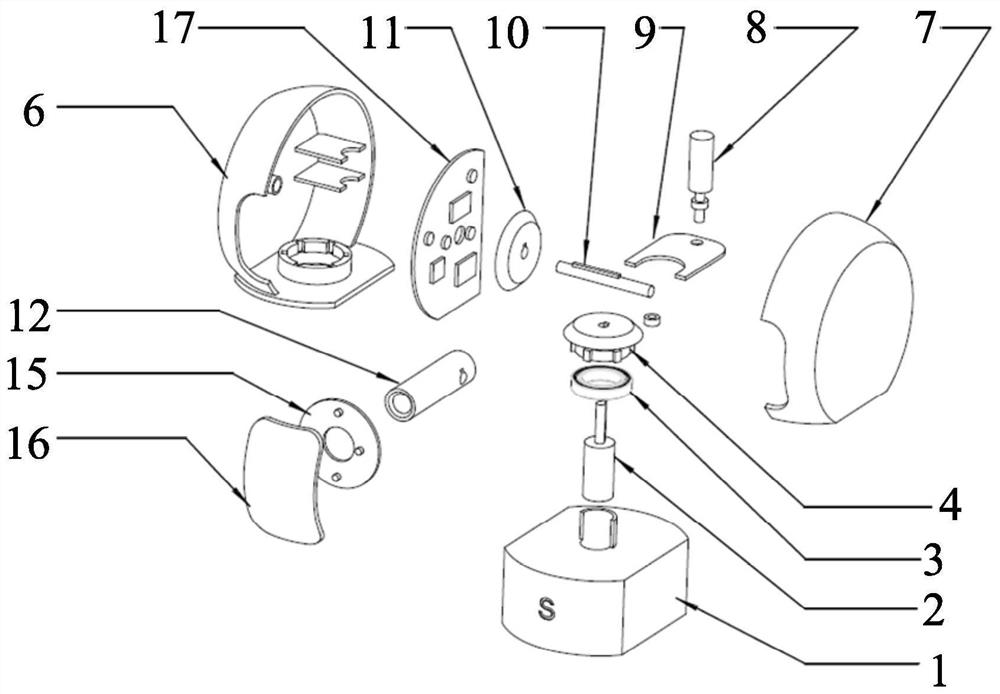

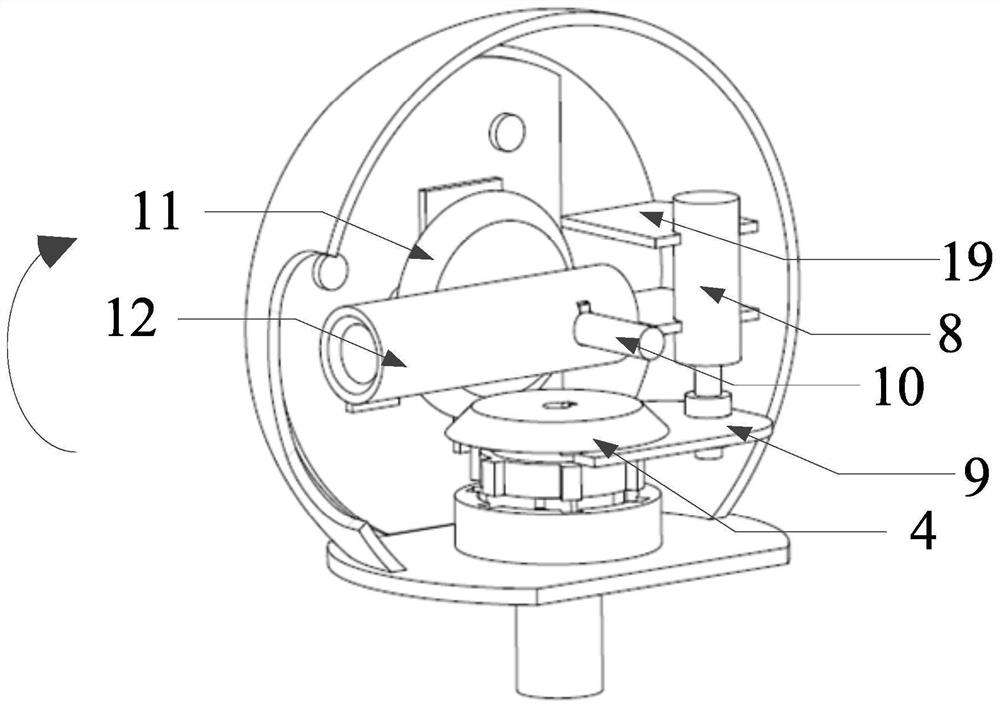

[0074] This embodiment provides a camera, which includes: a driving mechanism for driving the horizontal helical bevel gear assembly 4 to rotate; and a lifting mechanism 18 for driving the horizontal helical bevel gear assembly 4 to lift and lower, so that the horizontal helical bevel gear assembly 4 is lifted and lowered. The assembly 4 meshes with the vertical helical bevel gear 11 or engages with the groove 22 of the casing 5 to drive the vertical helical bevel gear 11 or the casing 5 to rotate, thereby realizing the vertical or horizontal rotation of the camera 12 .

[0075] The vertical rotation in this embodiment refers to the rotation of the camera 12 in a vertical plane. At this time, the camera 12 rotates around a horizontal axis as the rotation center axis. The horizontal rotation in this embodiment refers to the rotation of the camera 12 in a horizontal plane, and at this time, the camera 12 rotates around a vertically arranged axis as the rotation center axis.

[0...

Embodiment 2

[0084] A main control system 17 is arranged in the first housing 6 , and the main control system 17 is connected to the driving mechanism and the lifting mechanism 18 in communication. The main control system 17 is used for receiving user instructions to control the normal and efficient operation of the driving mechanism and the lifting mechanism 18 , so as to realize the vertical rotation and horizontal rotation of the camera 12 .

[0085] Specifically, the main control system 17 receives an instruction from the user, and the instruction is an instruction to rotate the camera 12 vertically or an instruction to rotate the camera 12 horizontally.

[0086] like Figure 7 As shown, when the command is to rotate the camera 12 vertically, the main control system 17 first sends the first command to control the lifting mechanism 18 to the lifting mechanism 18, and the lifting mechanism 18 immediately executes the first command. At this time, the first command is The lifting mechanis...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com