Energy-saving environment-friendly green building board laying device

A green building, energy saving and environmental protection technology, applied in construction, building construction, etc., can solve the problems of labor consumption, high cost, complex structure, etc., and achieve the effect of convenient use and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

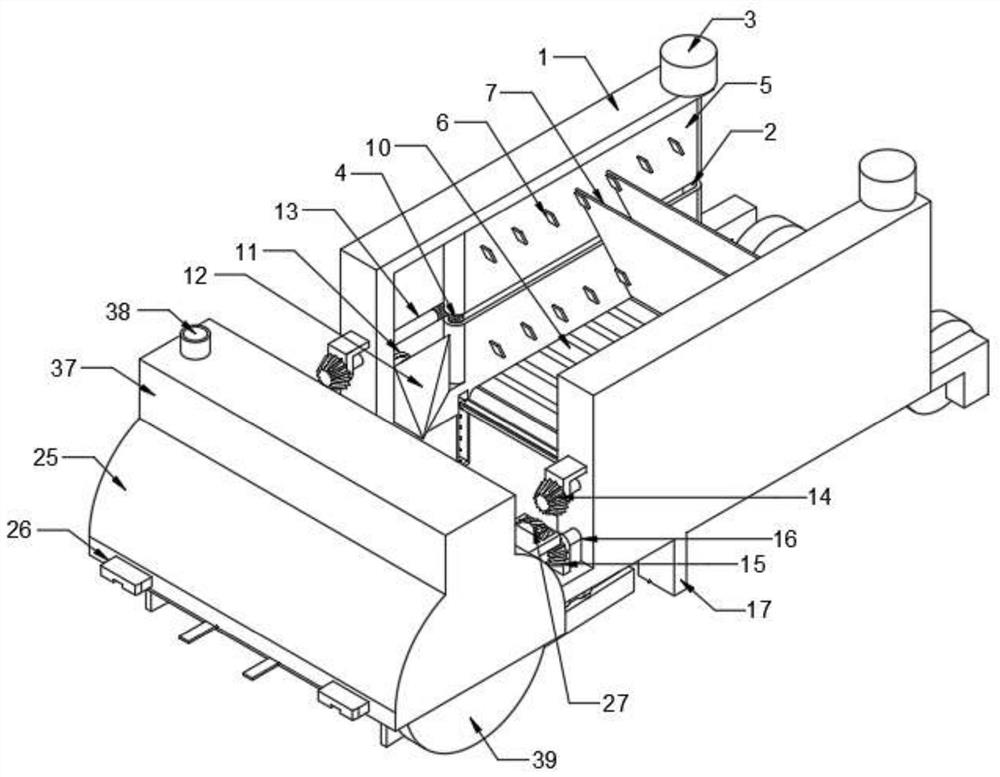

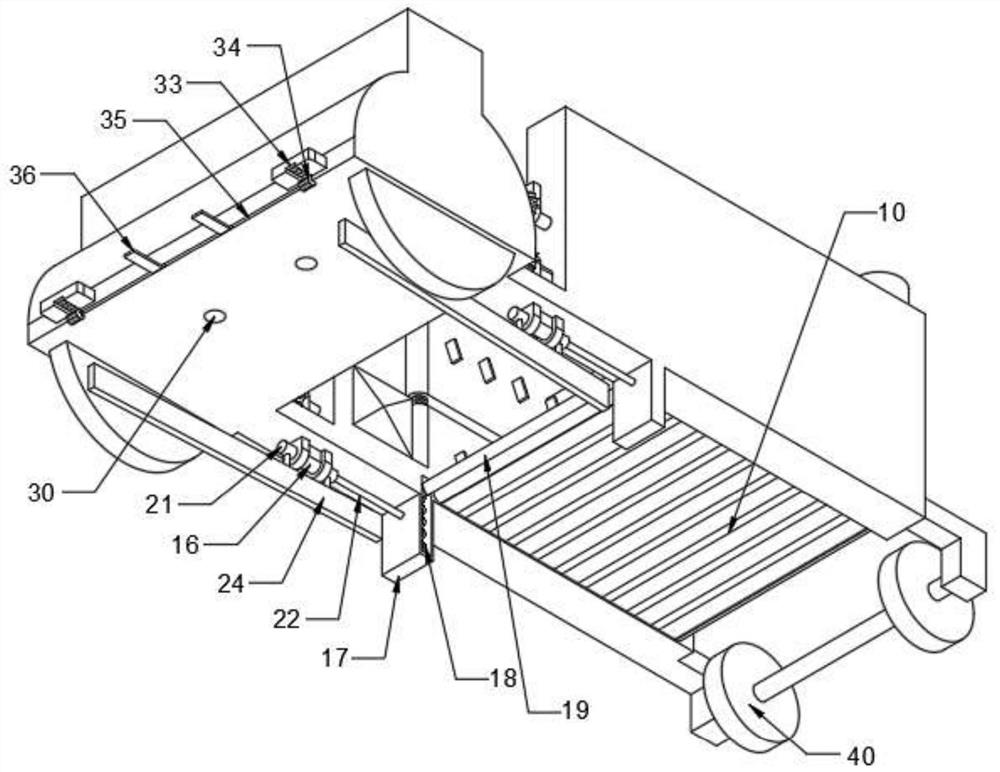

[0033] Example 1: Please refer to Figure 1-9 , in an embodiment of the present invention, an energy-saving and environmentally friendly green building board laying device includes a support plate 1 and a headstock 25, a drive motor 3 is installed on the upper end of the support plate 1, and a drive shaft 2 is connected to the lower end of the drive motor 3. The drive shaft 2 The bottom end is equipped with a first bevel gear 201, one side of the first bevel gear 201 is connected with a second bevel gear 901, a driving shaft 9 is installed between the two second bevel gears 901, and an auxiliary gear is arranged on one side of the driving shaft 9. Shaft 8, the second conveyor belt 10 is sleeved on the auxiliary shaft 8, a plurality of slots are provided on the second conveyor belt 10, the first conveyor belt 5 is sleeved on the driving shaft 9, the first conveyor belt 5 A fixed block 6 is installed on the top, the left side of the driving shaft 9 is provided with a driven shaf...

Embodiment 2

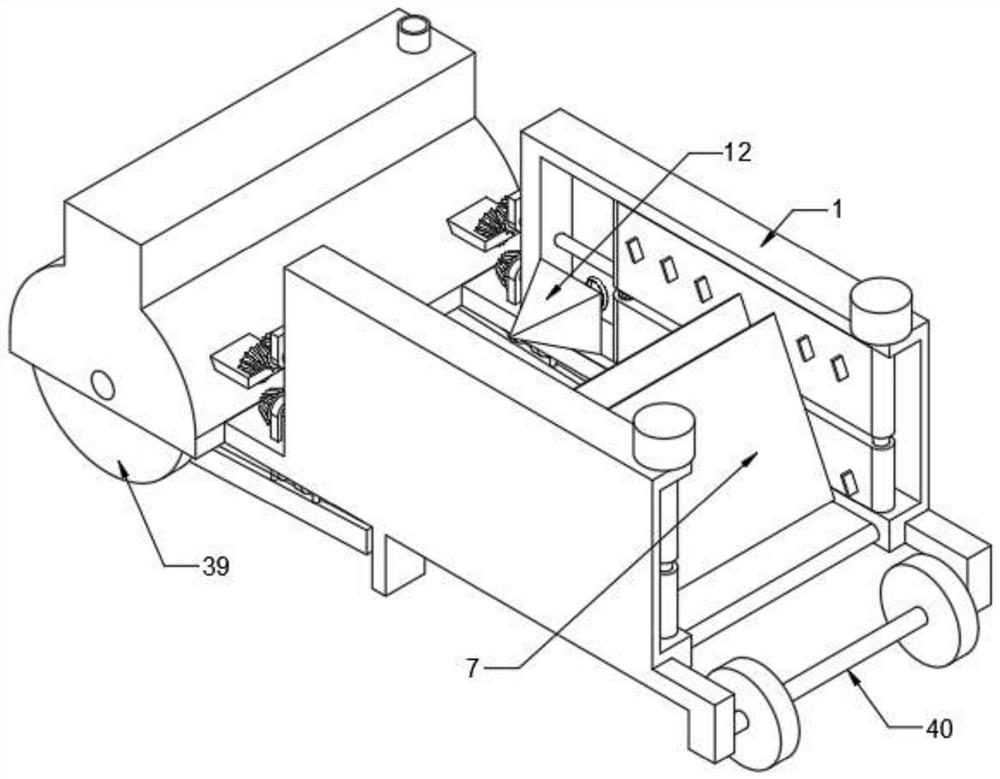

[0037] Embodiment 2: This embodiment is based on the previous embodiment: the upper end of the headstock 25 is equipped with a trough 37, the lower end of the chute 37 is connected with a first feeding pipe 30, and the right side of the first feeding pipe 30 is set There is a second feeding pipe 32, and a feeding port 38 is installed on the top of the trough 37;

[0038] A trough 37 and a feed port 38 are added at the position of the headstock 25 to store materials used for laying. When the pressing plate 26 is pressed against the wall and pressed into the headstock 25, the first through hole 29 is docked with the first feeding pipe 30 , so the position where the wall is laid can be unloaded. After leaving the wall position, the second feeding pipe 32 is docked with the second through hole 31, and the normal laying position can be unloaded.

[0039] The working principle of the present invention is:

[0040] On the support plate 1 of the device, the driving motor 3 drives the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com