A deploying and recovering device for a multi-joint submersible

A recovery device and multi-joint technology, which is applied in lifting devices, transportation and packaging, cargo handling equipment, etc., can solve the problems of complex oil circuit layout, difficult recovery methods, and cumbersome processes, so as to improve the efficiency of deployment and recovery and reduce recovery. The difficulty of the operation and the effect of the overall compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

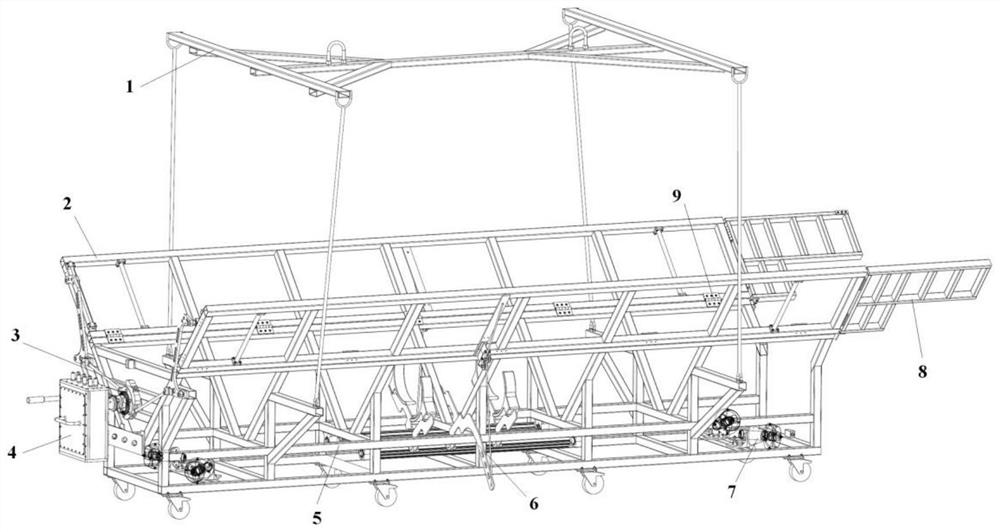

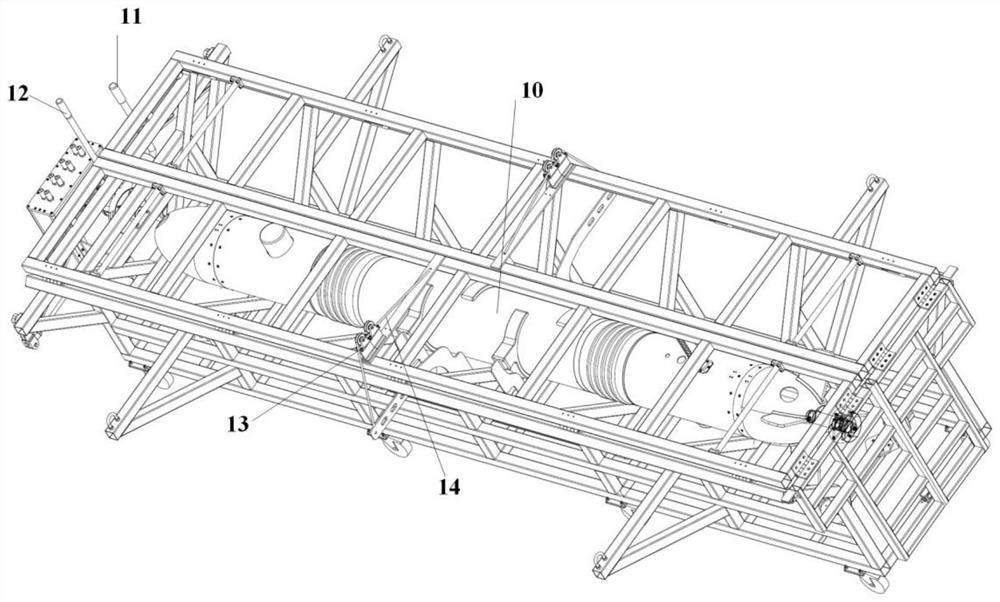

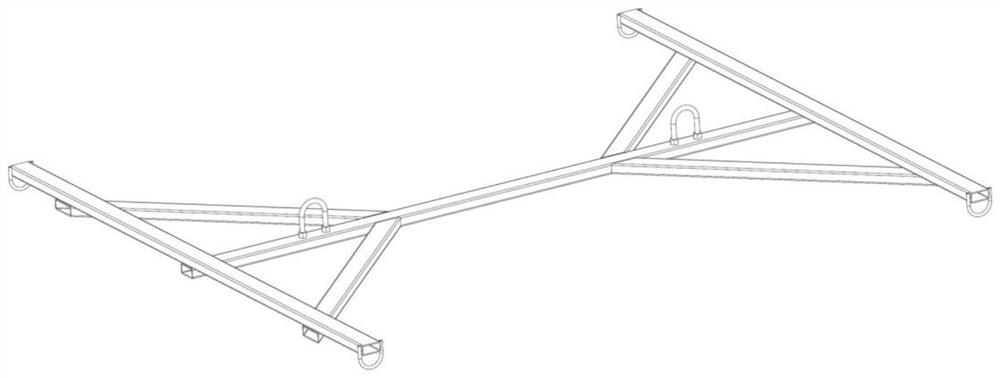

[0052] refer to Figure 1-Figure 2 , a deployment and recovery device for deep-sea multi-joint submersibles with manual / electric conversion function proposed by the present invention, including a hoisting structure 1, a basic load-carrying structure 5, a top door 2, a tailgate 8, a door opening mechanism 3, electrical and The transmission system 4, the cabin clamping structure 6, the position fine-tuning system 7 and the heavy hinge 9, and the multi-joint submersible 10 are placed in the V-shaped groove built by the basic bearing structure 5. A manual opening wrench 11 and a locking lever 12 are provided on the front side of the device. The top door 2 and the cabin body clamping structure 6 are connected by cables 14 , and a fixed pulley block 13 is arranged on the upper side of the top door 2 to support and guide the cables 14 .

[0053] The position fine-tuning system 7 is composed of four sets of propellers, installed on the propeller installation position at the bottom of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com