Perforated brick surface identification treatment system

A processing system and perforated brick technology, applied in decorative arts, embossed ornaments, lighting and heating equipment, etc., can solve problems such as failure to detect the degree of engraving, and achieve the effect of avoiding waste and ensuring quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

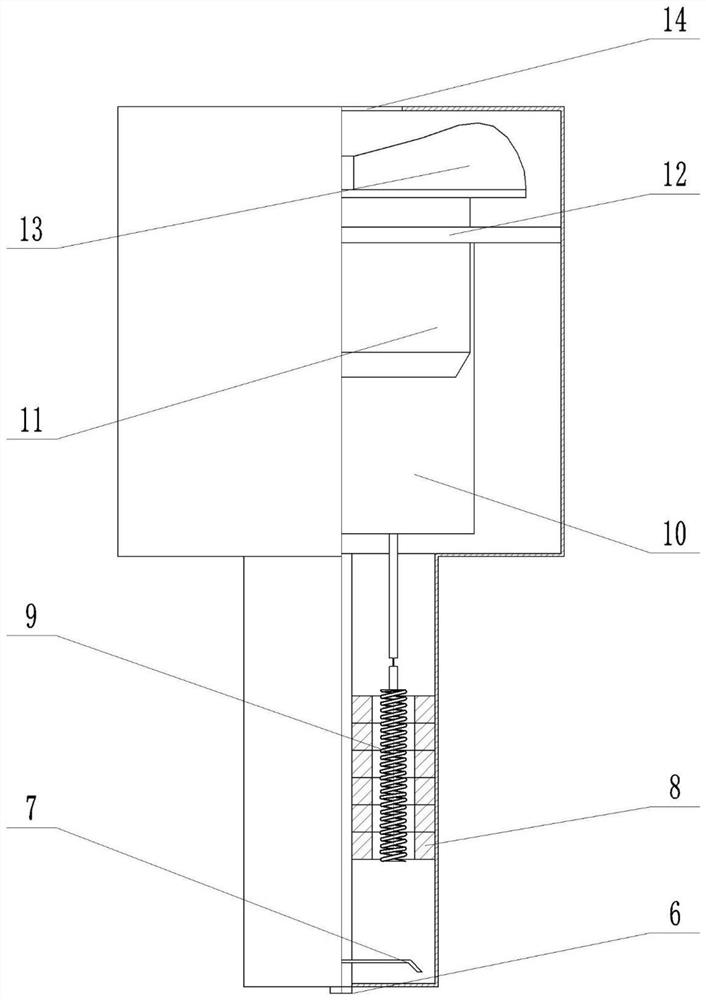

Image

Examples

Embodiment 2

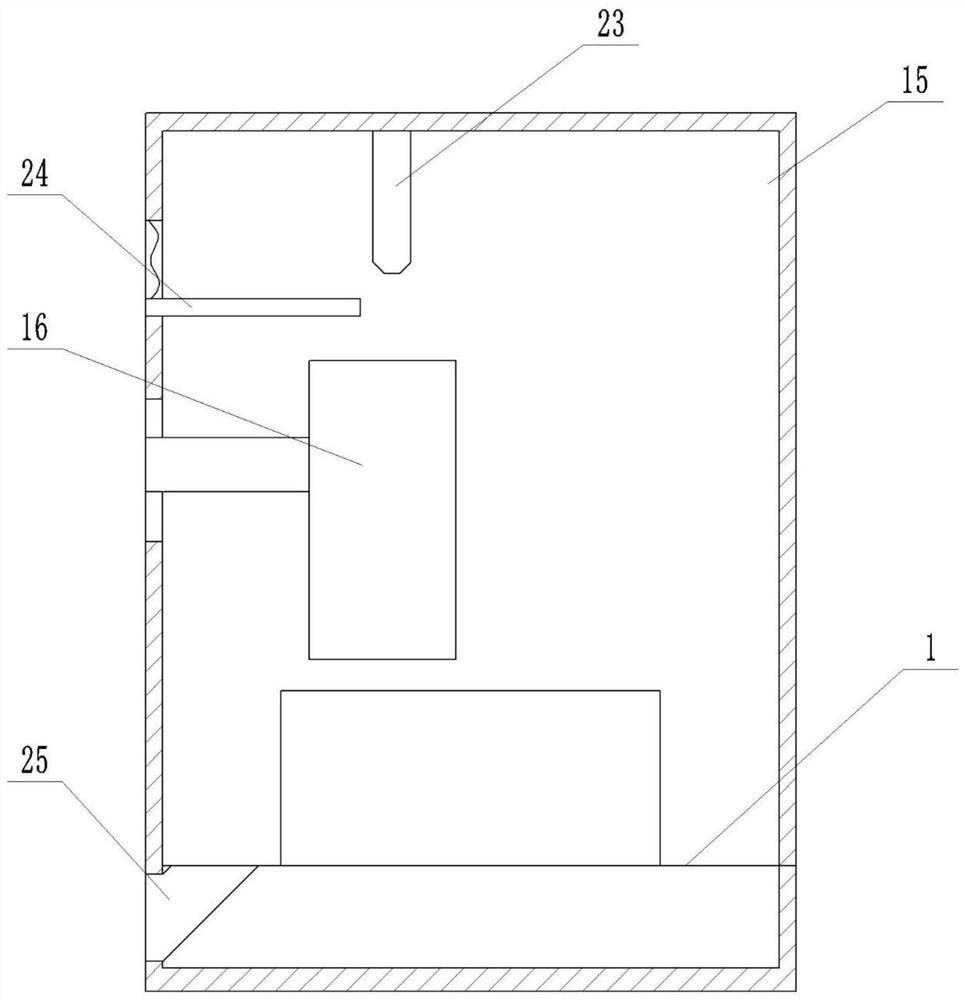

[0044] Example 2 (such as image 3 Indicated by)

[0045] Embodiment 2 The difference from the first embodiment is that the printing assembly is different, and the printing roller 18 in the printing assembly in the second embodiment is rotated on the printing frame 15, and the outside is provided with a driving device for adjusting the up and down distance. The printing roller 18 is eccentricly rotated and the convex one end is provided with a stamp that requires a print. The top of the printing roller 18 is provided with a sliding mounted contact switch 24, and a spring is provided between the outer end of the contact switch 24 and the printing frame 15. The top of the printing frame 15 is provided with a hot air port 23, and the hot air port 23 is connected to the waste heat generating device of the sintered porous brick, and the contact switch 24 controls the opening or closing of the hot air port 23. Due to the eccentric setting of the print roller 18, the intermittent contact ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com