Intelligent disassembling equipment for cascade utilization of a power battery

A power battery and step-by-step technology, applied in the field of mechanical processing, can solve the problems of time-consuming and labor-intensive disassembly, no function of moving parts after disassembly, and difficult precise positioning, etc., and achieve the effect of improving disassembly efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Example Embodiment

[0030] The technical solutions in the embodiments of the present invention will be apparent from the drawings in the embodiment of the present invention.

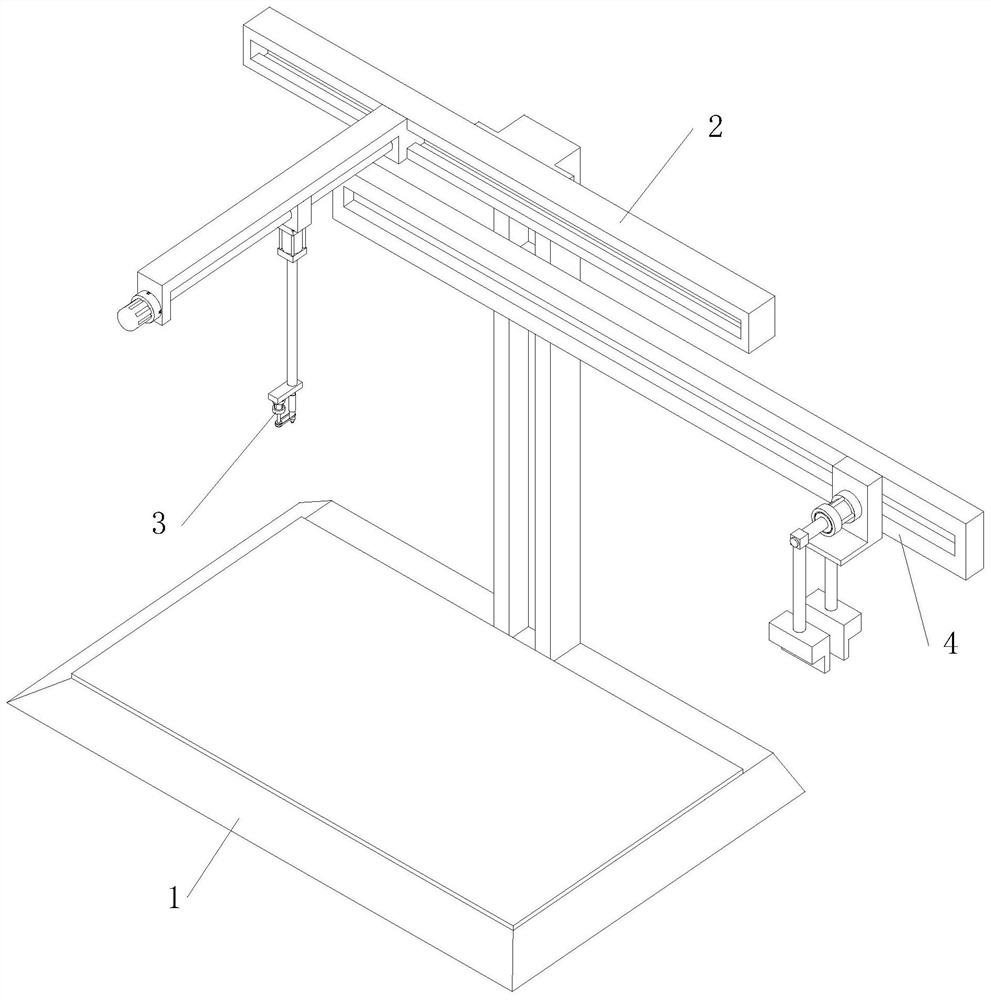

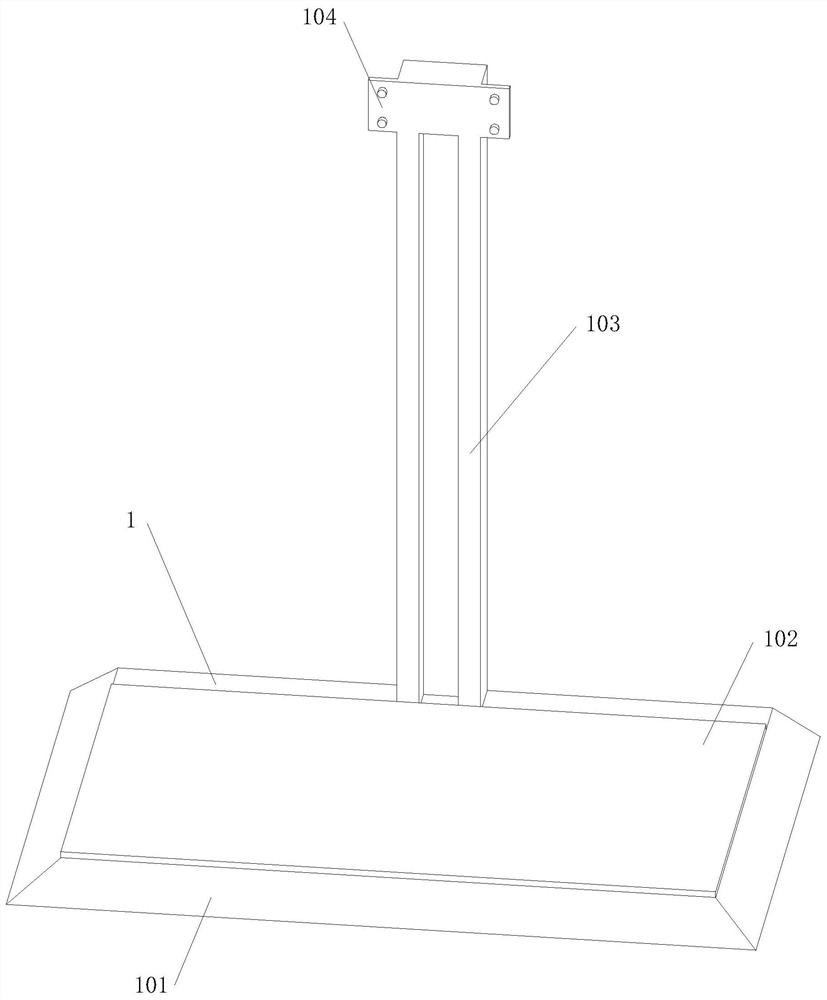

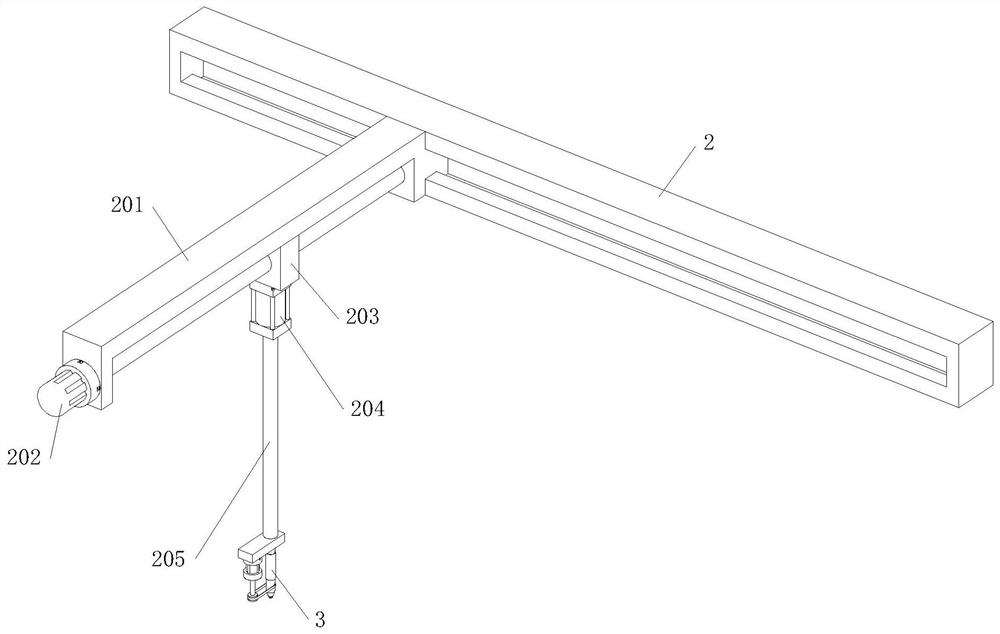

[0031] See Figure 1-6 As shown, the present invention is a power battery ladder that utilizes an intelligent disassembly apparatus, including the disassembly table 1, the second sliding rail 2, the disassembly assembly 3 and the third slide rail 4, and the upper side welding fixed station is fixed. The sliding rail 103 can drive the up and down movement of the third slide rail 4 by the first sliding rail 103, which is convenient for moving the part after the disassembly, reducing the labor intensity of the staff, and the top end of the first slide rail 103 The second sliding rail 2 is fixed, and the second sliding rail 2 is coupled to the stepping track 201, and the left and right movement of the disassembly assembly 3 can be driven by the second sliding rail 2, and the disassembly assembly can be driven by the step rail 201. T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com