Flexible edge rolling equipment for rear wheel cover

A rear wheel cover, flexible technology, applied in the superstructure, sub-assembly of the superstructure, transportation and packaging, etc., can solve the problems of inability to achieve flexible hemming operation, excessive pressure, and insufficient pressure on the hemming wheel, and achieves ingenious design. , The production process is simple, and the effect of preventing air pressure or overpressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

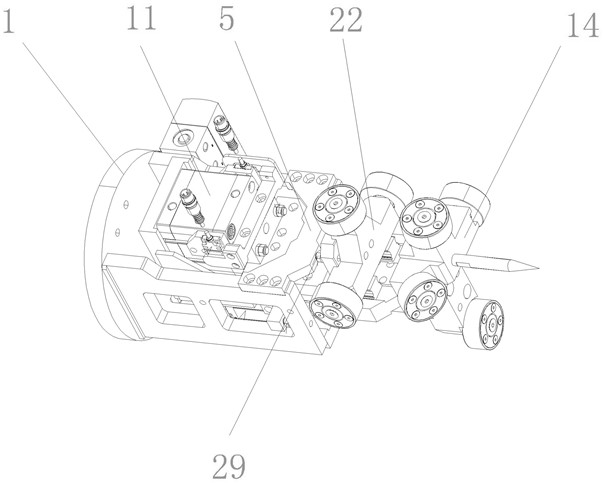

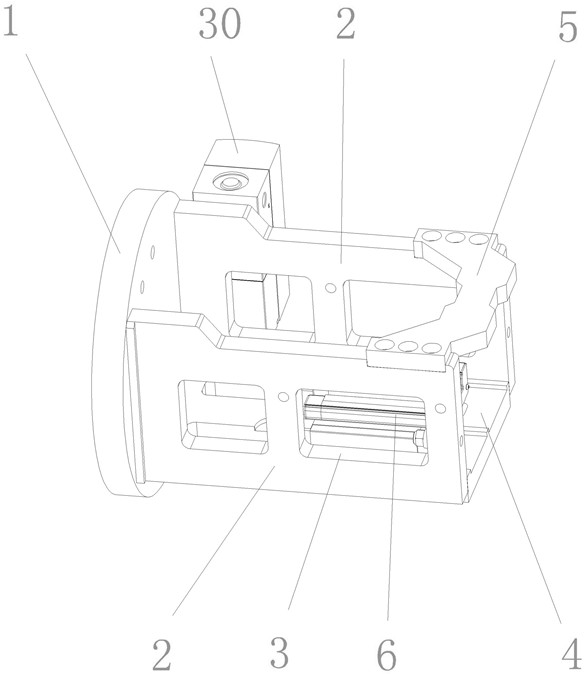

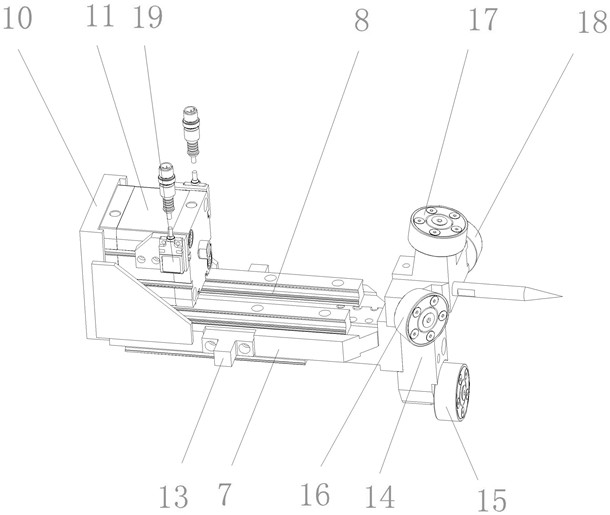

[0019] The specific implementation manner of the present invention will be described below with reference to the accompanying drawings. Such as Figure 1 to Figure 7 Shown: a rear wheel cover flexible hemming equipment, characterized in that: the equipment includes a base 1, the base 1 is connected with an outer support frame, the outer support frame includes two symmetrically distributed side plates 2, A limiting square hole 3 is provided on the side plate 2, a back plate 4 and a front limiting plate 5 are connected between the two side plates 2, a pair of first sliders 6 are fixedly arranged on the inner side of the back plate 4,

[0020] The device also includes a clamp wheel support plate 7, a pair of front slideways 8 and a pair of rear slideways 9 are respectively arranged on both sides of the clamp wheel support plate 7, wherein the rear slideways 9 are connected with the first slide block 6 sliding connection, the bottom of the clamp wheel support plate 7 is provided ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com