Urban rail vehicle chassis wiring method

A wiring method and technology for urban rail vehicles, which are applied in the field of underframe wiring of urban rail vehicles, can solve problems such as inconvenience in vehicle manufacturing, and achieve the effects of easy maintenance, good platform performance, and good electromagnetic compatibility.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with specific preferred embodiments, but the protection scope of the present invention is not limited thereby.

[0031] For the convenience of description, the relative positional relationship of each component, such as: the description of up, down, left, right, etc., is described according to the layout direction of the drawings in the specification, and does not limit the structure of this patent.

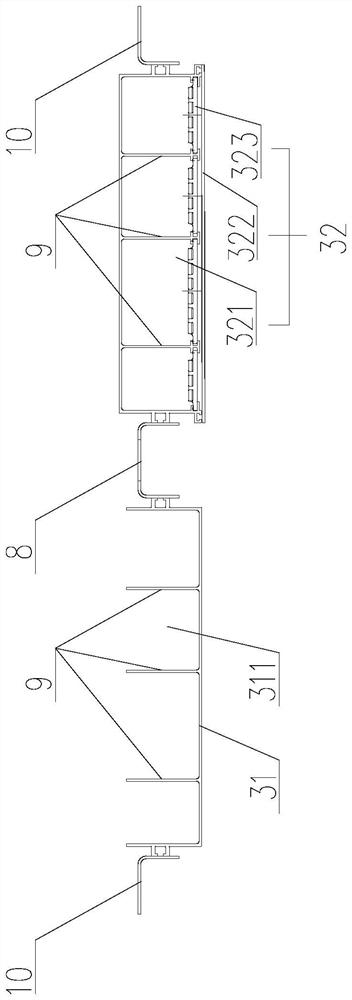

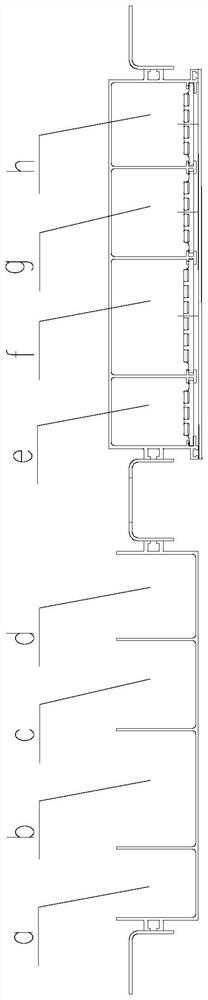

[0032] Such as figure 1 - Figure 4 As shown, an embodiment of the urban rail vehicle underframe wiring method of the present invention includes:

[0033] A mounted end box 2 is used at the end of the chassis 1;

[0034] In the equipment installation area in the middle of the underframe 1, that is, between the bogies at both ends of the car body, the central wire slot 3 is adopted, and the central wire slot 3 is installed using the three chutes 6 that come with the under frame 1, and the brake pipe 7 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com