Loading tray for logistics cargo transportation and using method of loading tray

A technology for cargo transportation and loading pallets, which is applied in the direction of transportation and packaging, containers, trolleys, etc., can solve the problems of high labor intensity and inconvenient use, and achieve the effect of reducing labor intensity, not easy to fluctuate, and moving stably

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

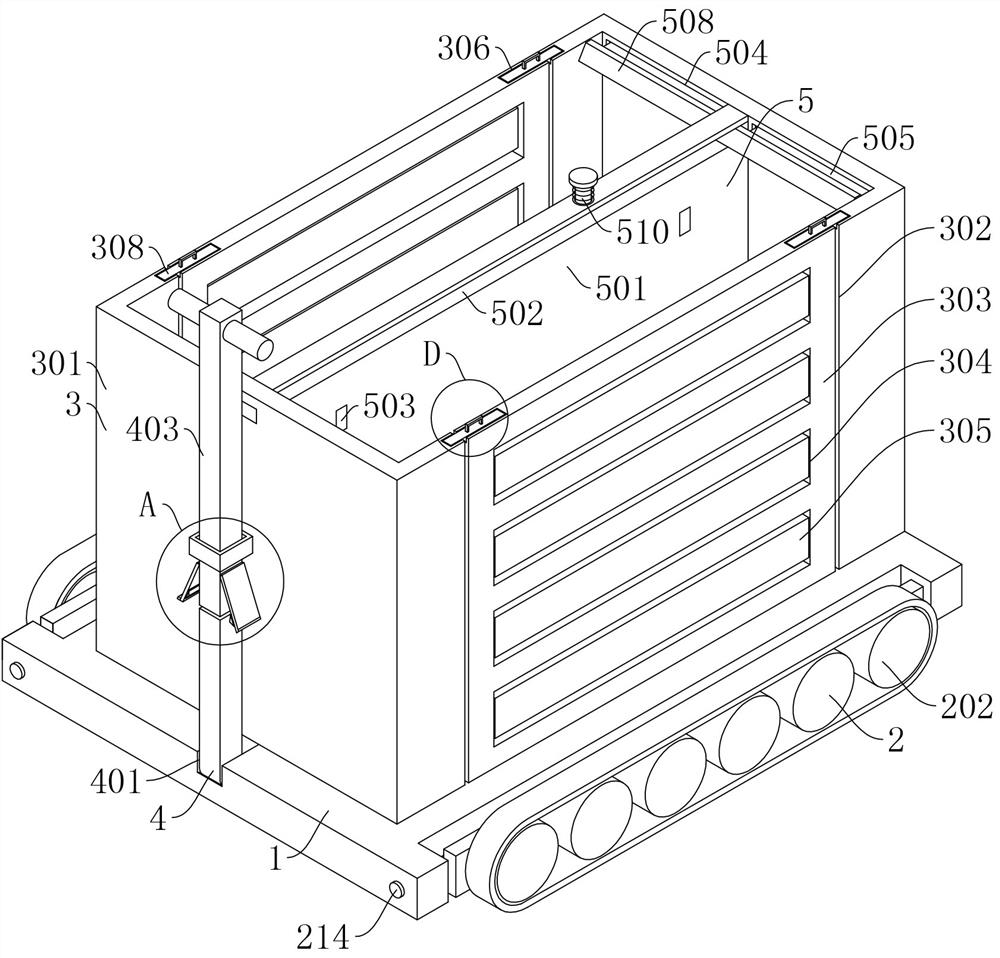

[0051] Such as figure 1 and Figure 13 As shown, this embodiment proposes a loading tray for logistics goods transportation, including a base 1, the front and rear sides of the base 1 are provided with a brake movement mechanism 2, and the top of the base 1 is provided with a climbing load for placing goods. Mechanism 3, the middle part of the top side of the base 1 is provided with a braking mechanism 4, and the middle part of the climbing and loading mechanism 3 is provided with a sealing mechanism 5; the braking moving mechanism 2 includes a crawler moving part and a roller moving part, and the braking moving mechanism 2 After turning, the roller moving part on it cooperates with the braking mechanism 4 and can be used to brake the crawler moving part; the climbing loading mechanism 3 is obliquely connected to the sealing mechanism 5 after structural transformation to form a ladder for climbing.

Embodiment 2

[0052] Embodiment 2: The scheme in Embodiment 1 is further introduced below in conjunction with specific working methods, see the following description for details:

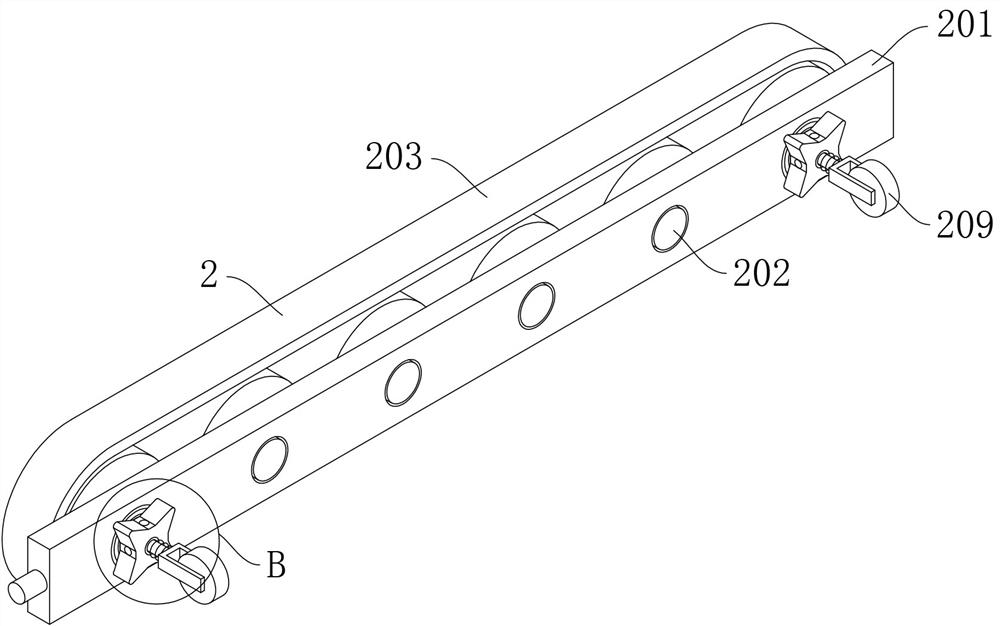

[0053] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 14 As shown, as a preferred embodiment, on the basis of the above method, further, the brake moving mechanism 2 includes a rotating plate 201 with two ends arranged on one side of the base 1 through bearings, and one side of the rotating plate 201 is connected with a The plurality of pulleys 202 and the same crawler belt 203 are wound around the outer portions of the plurality of pulleys 202 .

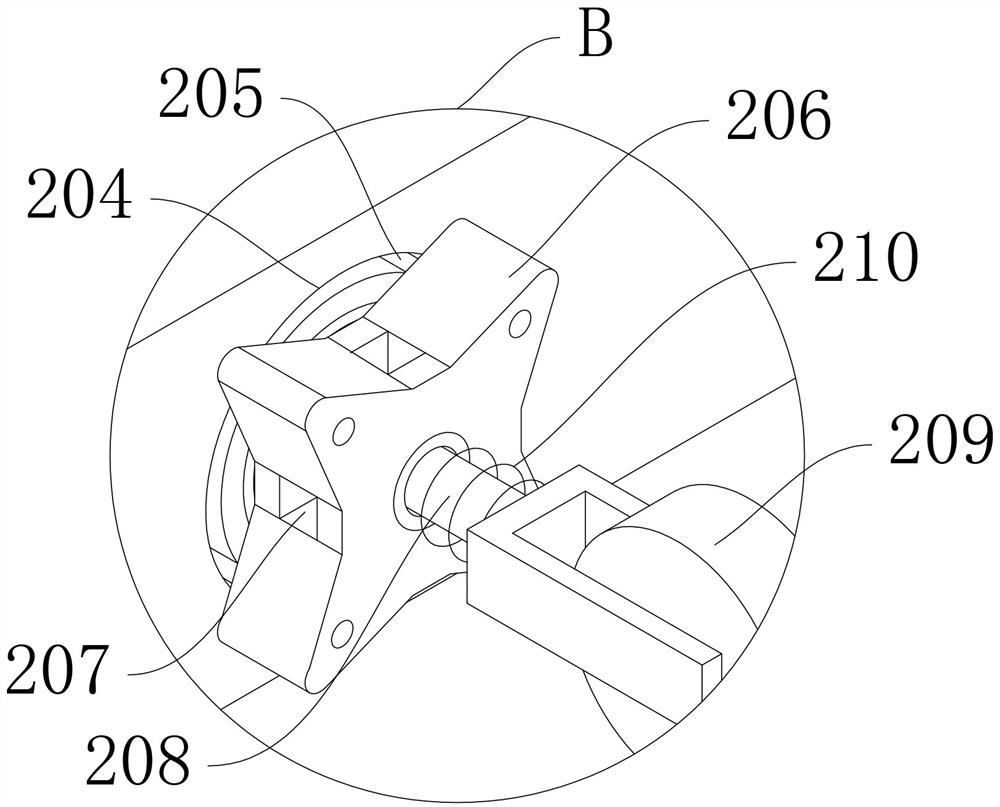

[0054] Such as figure 1 , figure 2 , image 3 , Figure 4 and Figure 14 As shown, as a preferred embodiment, on the basis of the above method, further, the roller moving part includes an annular groove 204 opened at both ends of the side of the rotating plate 201, and the inside of the annular groove 204 is slidably connected with four T-sha...

Embodiment 3

[0062] Embodiment 3: The scheme in embodiment 1 and embodiment 2 is further introduced below in conjunction with specific working mode, see the following description for details:

[0063] A method for using a loading pallet for logistics cargo transportation, comprising the following steps:

[0064] Step 1. Loading: Load the goods into the climbing loading mechanism 3, and by operating the braking mechanism 4, the sealing mechanism 5 seals one end of the climbing loading mechanism 3, so that the base 1 goes up on the stairs When moving, the goods are not easy to fall off from the inside of the climbing loading mechanism 3; the goods are put into the inside of the loading frame 301, and by rotating the handrail 403, the handrail 403 drives the hook 512 and the second connecting rope 513 to move, so that the inclined block 508 Moving under the transmission of the hook 512 and the second connecting rope 513, the packing cloth 505 is driven to protrude from the inside of the slot ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com