Circuit board inner layer punching machine die automatic position adjusting structure and position adjusting method

An automatic positioning and punching machine technology, applied in metal processing and other directions, can solve the problems of high labor intensity, scrapped circuit boards, and unsatisfactory accuracy, and achieve the goal of reducing labor intensity, reducing assembly processes, and improving work efficiency. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

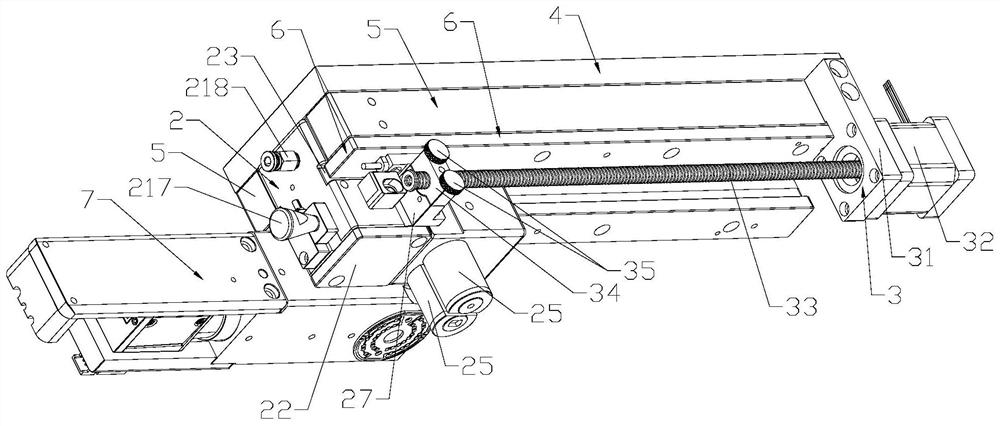

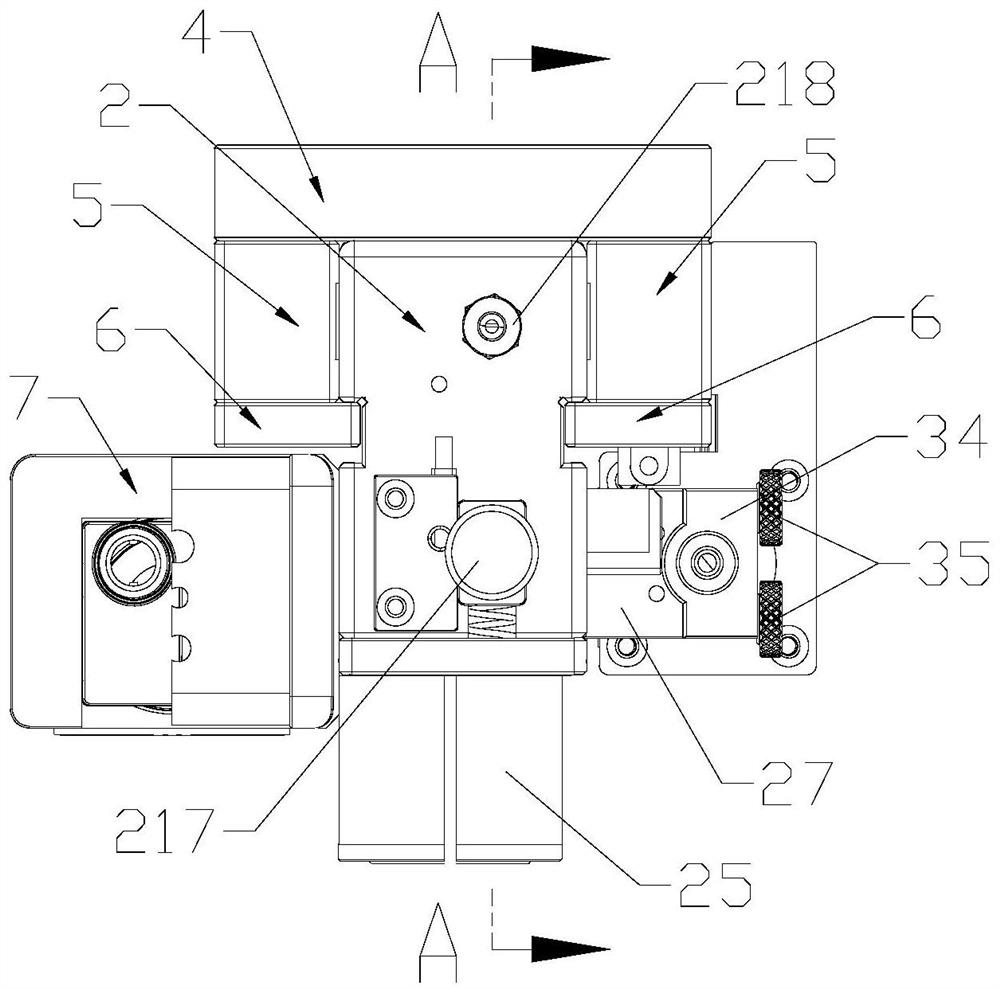

[0029] Please refer to Figure 1-4 , the present invention provides a circuit board inner layer punching machine mold automatic adjustment structure, which includes a mold 2 carrying an industrial camera 7 and at least one punching needle 1, and is used to drive the mold 2 to move to drive the punching needle 1. A displacement drive mechanism 3 that moves to a designated position, a positioning plate 4 with several positioning holes 41, and the positioning holes 41 are arranged along the moving path of the mold 2; wherein, the mold 2 also has a positioning assembly 21, The positioning assembly 21 includes a positioning pin 211 matched with the positioning hole 41 and an in-and-out driving mechanism for driving the positioning pin 211 into and out of the positioning hole 41 .

[0030] Specifically, the positioning assembly 21 also includes a sliding groove 212 and a return spring 213, the sliding groove 212 is arranged on one side of the mold 2, the positioning pin 211 is arran...

Embodiment 2

[0042] This embodiment also provides a method for automatically adjusting the mold of a circuit board inner layer punching machine realized by the adjusting structure of Embodiment 1, which includes the following steps: the in-out driving mechanism controls the positioning pin to escape from the positioning hole. At this time, there is an industrial camera The positioning plate with several positioning holes relative to the mold with at least one punching pin is in a free state, the displacement drive mechanism drives the mold to move to the designated position, and the in-out drive mechanism controls the positioning pin to enter the positioning hole at this position. At this time, the mold is relatively The positioning plate is in a fixed state to complete the adjustment of the mould.

[0043] Specifically, the process of the entry and exit drive mechanism controlling the movement of the positioning pin is as follows: after the air is inflated into the sealed cavity through th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com