Reaction device with purification function and for high polymer material

A technology of polymer materials and reaction devices, applied in chemistry/physics/physicochemical fixed reactors, separation methods, separation of dispersed particles, etc., can solve problems such as environmental impact, inability to adjust the specifications of reaction devices, etc., to avoid pollution, Ease of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

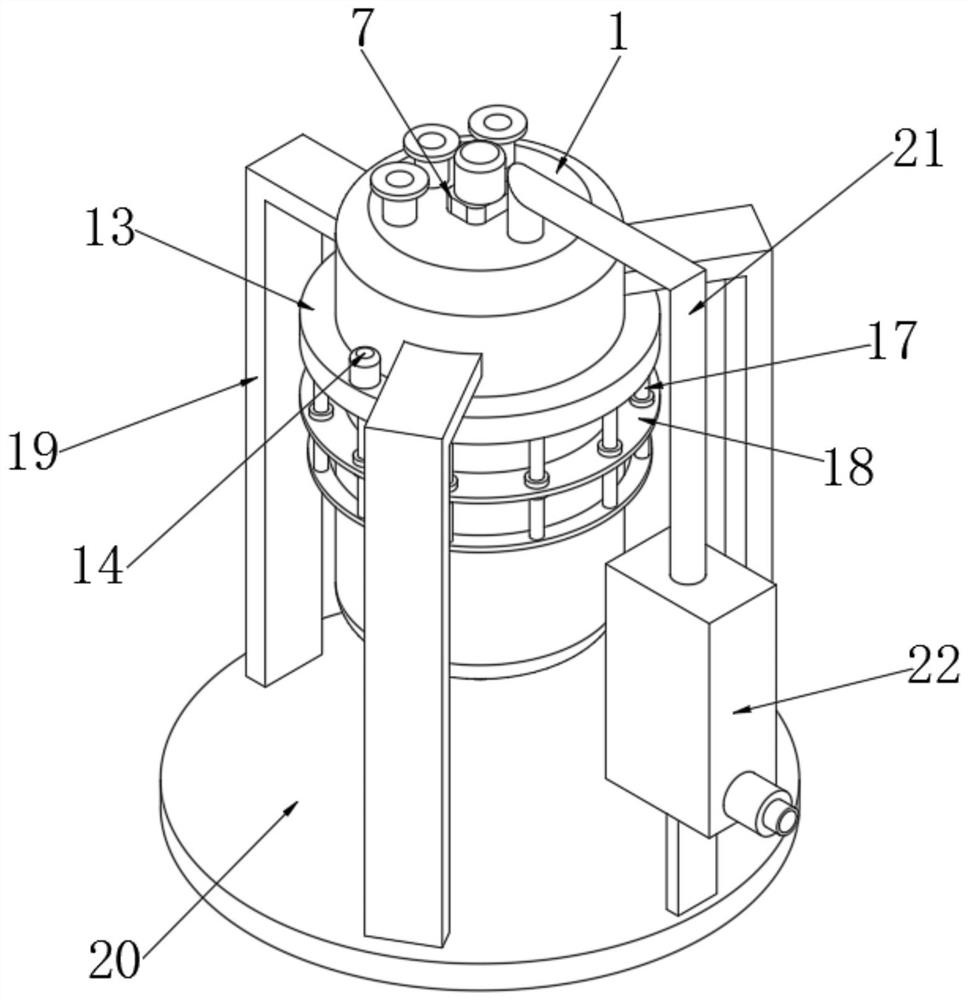

[0035] As an embodiment of the present invention, a reaction device with purification function for polymer materials, the specific operation steps of the reaction device are as follows:

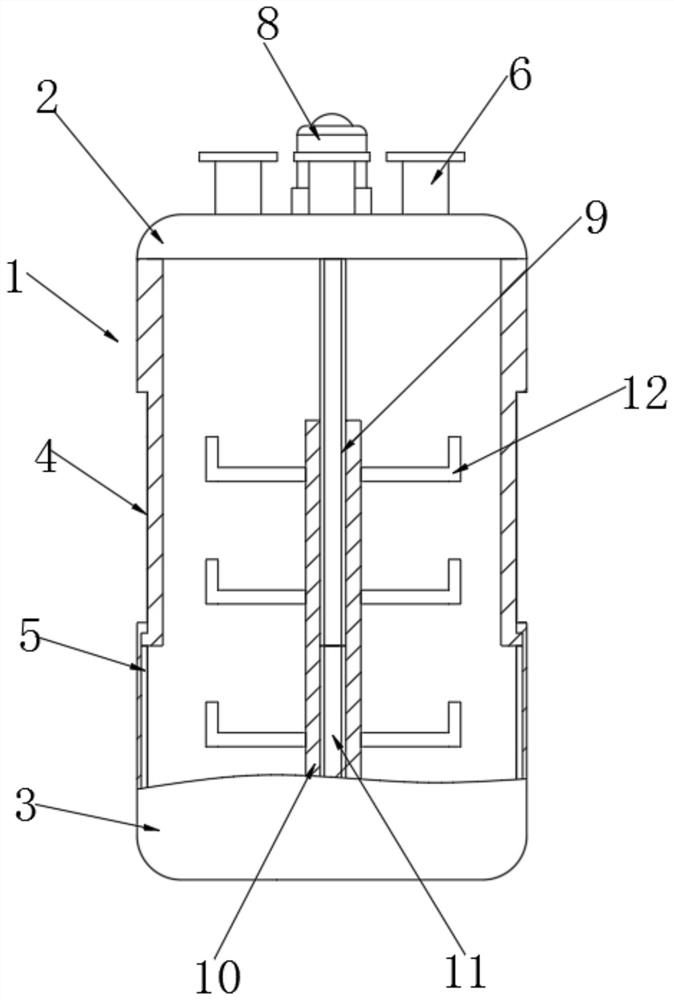

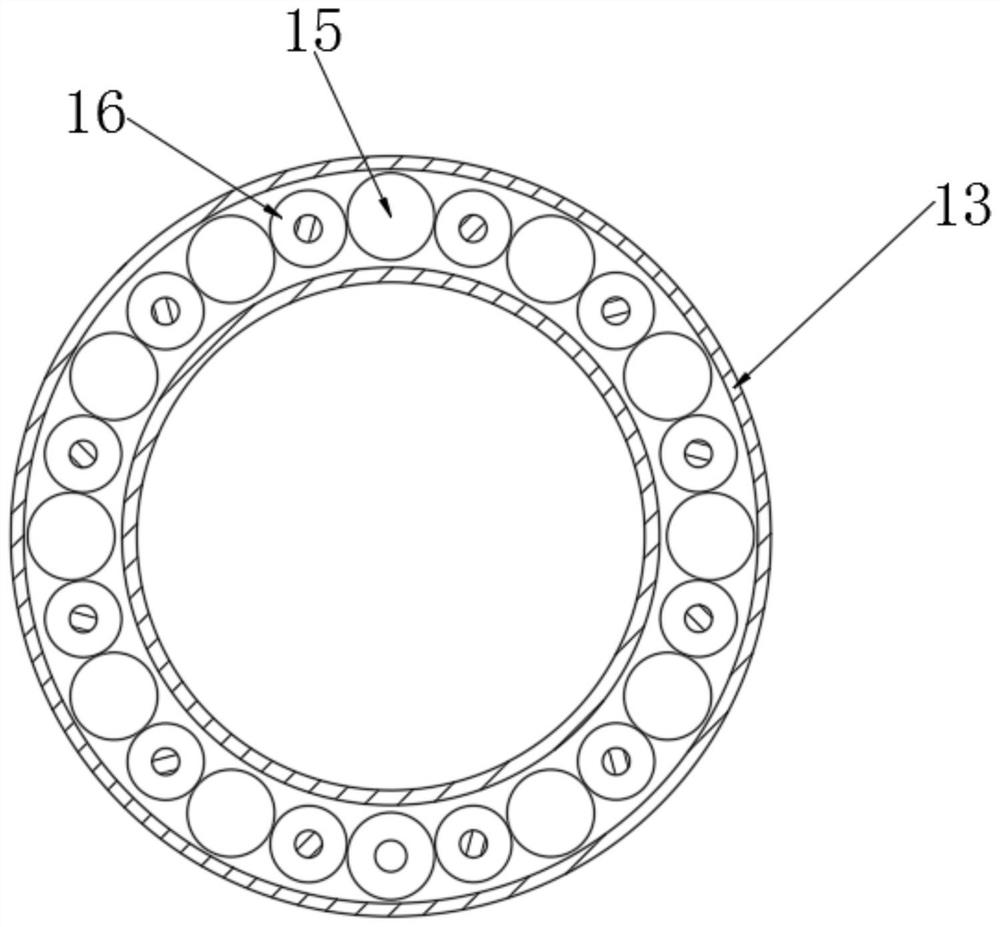

[0036] Step 1: Drive a rotary tooth 15 in the transmission cover 13 to rotate through the second motor 14, drive the threaded rod 17 to rotate through the meshing transmission of the rotary tooth 15 and the transmission tooth 16, and cooperate with the threaded sleeve threaded on the fixed ring 18, Drive the bottom kettle 3 to slide outside the bottom of the top kettle 2 to adjust the internal space of the reaction kettle 1, and at the same time the hexagonal shaft 9 moves in the socket 11 of the rotating shaft 10, and the connection between the hexagonal shaft 9 and the rotating shaft 10 is always maintained;

[0037]Step 2: When the raw material enters the reaction kettle 1 through the feeding pipe 6, the first motor 8 works at this time, and the speed adjustment of the reducer 7 drives the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com